Temperature range

- -80 to +2000°C

Components

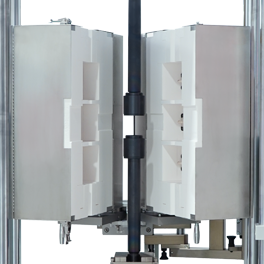

- Temperature chambers

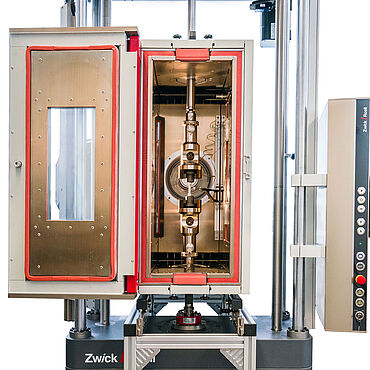

- Furnaces

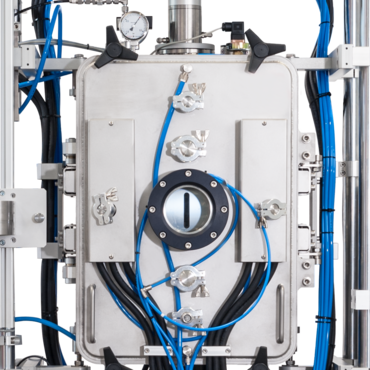

- Vacuum chambers

- Induction heating

- Temperature controller

- Specimen temperature measuring device

- Extensometers

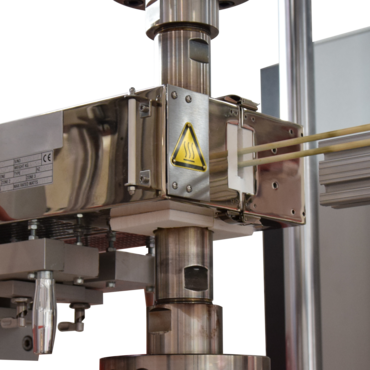

- Load strings

Advantages

- Precise temperature

- Reliable strain measurement

- Secure specimen gripping

Wide selection of modular accessories for different environmental conditions in creep testing

For use with different applications and environmental conditions in creep testing, ZwickRoell offers a wide variety of modular accessories up to +2,000°C for the Kappa creep testing machines. The optimal combination of heating system, precise temperature control, suitable thermocouples, load strings and coordinated extensometers is the basis for reliable test results in creep testing.

Get an overview of the available accessories for the Kappa series and let one of our engineers assist you in your selection.

Overview of heating systems for creep testing

Downloads

Name

Type

Size

Download

- Product information: High-temperature furnace up to 1,200°C PDF 725 KB

- Product information: Load string for creep tests up to 1,200°C PDF 1 MB

- Product information: Load string for creep tests up to 1,500 °C PDF 1,023 KB

- Product information: Contact-type high-temperature extensometer PDF 760 KB