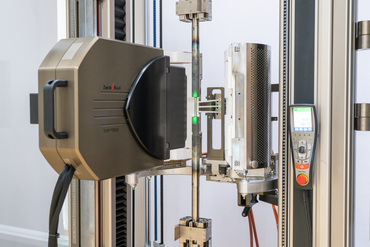

Laser extensometers

Non-contact and precise measurement without gauge marks at ultra-high temperatures up to +2,000 °C? Not a problem with the laser extensometer. The laserXtens is ideal for optical / non-contact strain measurement on different materials, in different environmental conditions and in a wide temperature range from -80 °C to +2,000 °C. Due to the measuring principle, it is not necessary to apply measuring marks, which saves time and money.

Advantages laserXtens selection VIDEO Downloads Advanced functionality Request a consultation

The advantages of laser extensometers

- Ideal for changing temperature ranges and ambient conditions (air, vacuum, inert gas, etc.)

- Universally applicable for various materials: metals, refractory materials, ceramics, graphite, glass

- Wide variety of specimen shapes and sizes including sensitive specimens and mini specimens from 1.5 mm

- Non-contact strain measurement: no influence on the specimen, maintenance-free

- No specimen marking: Cost and time savings

- High accuracy and precision in the micro and macro measurement range

- Compensation of lateral specimen movements (out-of-plane)

- Compliance with all standard requirements in high-temperature testing, e.g. ISO 6892-2, ASTM E21, DIN EN 2002-002

Optical strain measurement at high temperatures - how it works

The laser extensometer illuminates the specimen with green or blue laser light (depending on the temperature range), creating a speckle pattern on the specimen surface. Lenses with special filters allow only the desired laser light to pass through, blocking the interfering red light from the glowing or hot specimen. This makes it possible to measure the change in length even at very high temperatures.

The specimen surface with the speckle patterns is captured with one or two cameras. Two evaluation fields are set within the camera image (field of view) and thereby two sub-patterns are defined and tracked. The displacement of each speckle pattern is calculated using a highly advanced correlation algorithm. The elongation of the specimen is calculated from the difference of these displacement measurements.

Measure without marking and without influence on the specimen

Thanks to its unique technology, the laser extensometer does not require specimen marking. Applying measurement marks in temperature chambers, high-temperature ovens or even vacuum chambers would be very difficult anyway due to the ambient conditions and high temperatures. This effort is eliminated when using thlaserXtens, saving time and cost, especially with high specimen throughputs.

Due to the non-contact strain measurement, the laserXtens has no mechanical contact with the specimen and does not influence it with the laser light. This advantage is particularly beneficial for sensitive specimens and high temperatures. The optimally matched high-temperature components, such as laserXtens, temperature control unit, specimen temperature measurement, etc., guarantee reliable test results even under difficult ambient conditions. High-temperature furnaces, vacuum chambers and temperature chambers can remain closed during the entire test. The laser extensometer measures the specimen strain from the outside via an furnace port or through a glass window.

Compensation of lateral specimen movements (out-of-plane)

Many test setups specifically for high-temperature testing allow the specimen to align itself at the start of the test. This movement into the center of the test axis can be towards or away from the camera. This is especially common with small specimens. A change in the specimen distance to the camera does however, in a trapezoidal field of view, result in an magnification/demagnification of the specimen, whereby the test results are influenced. The telecentric lens of the laserXtens compensates for these lateral specimen movements and minimizes measurement error.

Laser extensometer for high-temperature testing

laserXtens 2-120 HP/TZ |

laserXtens 1-32 HP/TZ | |

|---|---|---|

| Temperature range | -80°C to +1,600°C | -80°C to +2,000°C |

| Temperature control |

|

|

| Typical applications |

|

|

| Typical standards |

|

|

| Number of cameras | 2 | 1 |

| Measurement range | max. 120 mm | max. 32 mm |

| Accuracy class to EN ISO 9513 | 0.5 | 0.5 |

| Laser light | Green | Green and blue |

Laser extensometer applications in high-temperature testing

Laser extensometer advanced functionality

The range of applications of the laser extensometer can be expanded with various advanced functionality options. With the various functions such as strain distribution, change in width, test re-run, etc., you can get even more out of your strain measurement.

Strain distribution: every specimen counts

A break outside the gauge length causes costs and additional time for specimen preparation and retesting. This can be prevented with the strain distribution option.

During the test, the testing software automatically places the gauge length symmetrically around the break point.

The workaround offered by ISO 6892-1 in Annex I to validate breaks outside the gauge length is also activated effortlessly by our software; calculation and validation according to standard specifications run automatically and in real time. No need to manually measure and recalculate the specimen as was the case before.

Test Re-Run: re-calculate instead of re-testing

The test re-run function can be used to virtually repeat and recalculate the test with a modified initial gauge length. You save time on specimen preparation and testing and can run different evaluations on one and the same specimen.

During the test, the testing software records the image series. You can later use these to change the size and position of the initial gauge length as required. One click starts the recalculation and all characteristic values are recalculated on the basis of the new gauge length. Each recalculation is displayed separately, making comparisons simple and clear.

2D dot matrix

This option supports two-dimensional measurement of points that are selected with an evaluation field as partial patterns from the overall pattern generated by laser light. By measuring the displacement between the fields, it is possible to determine local strains and inhomogeneities of the specimen under load. X and Y coordinates as well as the distances between dots are available as measured values.

Up to 100 measurement dots can be measured in any desired arrangement or in matrix form. Display in testXpert III is limited to 15 channels.

This option uses only one camera for measurement; any other cameras present are switched off beforehand.

Measurement of the change in width / transverse strain

With this option, biaxial measurements can be performed: In addition to the longitudinal strain, transverse strains can also be recorded—for example the change in width. Alternatively, change in width can naturally be measured alone.

Two versions are available for measurement of transverse strain:

- Direct measurement on the specimen edge without additional markings (required for the determination of the r-value). For this version a backlight is required.

- Local measurement on the specimen surface via pattern recognition

Deflection measurement

The laser extensometer can also be used for flexure tests. There are several options for measuring specimen deflection, depending on the type of test and the specimen condition and properties:

- Measurement with laser light on the specimen (pattern recognition)

- Measurement of deflection in the test axis