Max. measurement range

- 25 mm

Temperature range

- Ambient temperature

- Up to 250°C

Material

- Metals

- Plastics

- Fiber-reinforced composites

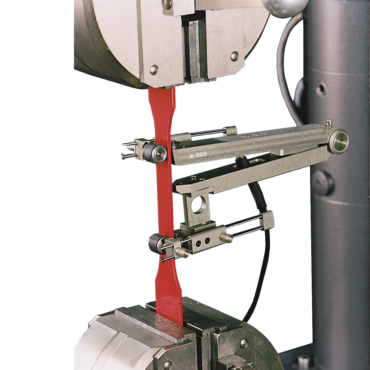

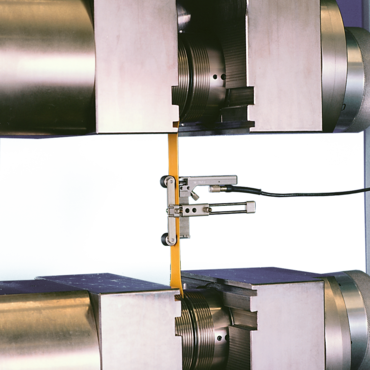

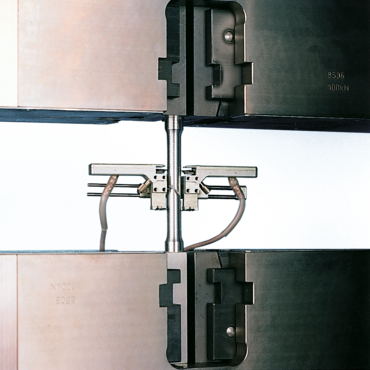

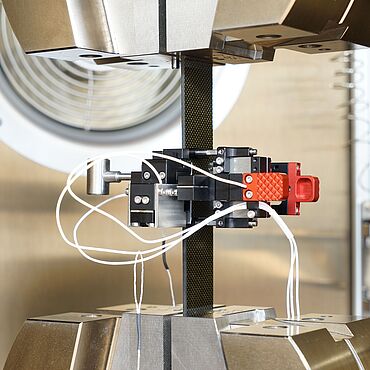

Strain gauge clip-on extensometer

Strain gauge clip-on extensometers are manual clip-on extensometers, that are clamped to the specimen. With various preset gauge-lengths they are suitable for use on metal and plastic specimens.

- Measuring systems possess excellent linearity, providing reliable test results.

- Lightweight, miniaturized construction, ideal for short specimens.

Advantages & features

- Excellent linearity for reliable test results.

- High resolutions enable measurement of very small deformations during test.

- Lightweight, miniaturized construction, ideal for specimens with small parallel length.

- Initial gauge length can optionally be reset from 10 to up to 100 mm using extension pieces (does not apply to Type DMS Length 1).

- Temperature-resistant measurement systems for use from -50°C to +200°C.

- Extensometers for two-sided measurement of specimen deformation, enabling exact determination of Young's modulus and engineering elastic limit.

- Variable measurement options are possible on extensometers with 2 separate measurement systems; individual signals or mean-value signal can be displayed.

- While attached to the specimen the extensometer is prevented by limit stops from exceeding the measurement travel and protected in the event of specimen break (Type DMS Length 1 only).

Extension measurement in pictures

Technical overview

| Description | Value | |

| Type | Strain gauge length 1 | |

| Item No. | 057808 | |

| Measuring system | Single-sided strain gauge system | |

| Initial gauge length | 25 | mm |

| Modifiable to | 50 | mm |

| Measurement travel | ||

| Tensile | 25 | mm |

| Compression | - | mm |

| Specimen dimensions, max. | ||

| Round specimen, Ø | 28 | mm |

| For flat specimens (d x w) | 28 x 30 | mm |

| Specimen dimensions, min. | ||

| Round specimen, Ø | 1 | mm |

| For flat specimens (d x w) | 1 x 1 | mm |

| Accuracy to EN ISO 9513 | Class 0.5 | |

| Weight | 95 | g |

| Mounted height | Gauge length + 2 | mm |

| Number of sensors | 1 | |

| Type of output signal | Individual signal | |

| Ambient temperature | > 0 ... +60 | °C |

| Factory calibration | 21 | °C |

| Description | Value | |

| Type | Strain gauge length 2 | |

| Item No. | 057809 | |

| Measuring system | Single-sided strain gauge system | |

| Initial gauge length | 20 | mm |

| Modifiable to | 10 | mm |

| Measurement travel | ||

| Tensile | 2 | mm |

| Compression | 1 | mm |

| Specimen dimensions, max. | ||

| Round specimen, Ø | 25 | mm |

| For flat specimens (d x w) | 25 x 25 | mm |

| Specimen dimensions, min. | ||

| Round specimen, Ø | 1 | mm |

| For flat specimens (d x w) | 1 x 1 | mm |

| Accuracy to EN ISO 9513 | Class 0.5 | |

| Weight | 45 | g |

| Mounted height | 24 | mm |

| Number of sensors | 1 | |

| Type of output signal | Individual signal | |

| Ambient temperature | > 0 ... +60 | °C |

| Factory calibration | 21 | °C |

| Description | Value | |

| Type | Strain gauge length 3 | |

| Item No. | 057810 | |

| Measuring system | Single-sided strain gauge system | |

| Initial gauge length | 20 | mm |

| Modifiable to | 10 | mm |

| Measurement travel | ||

| Tensile | 2 | mm |

| Compression | 1 | mm |

| Specimen dimensions, max. | ||

| Round specimen, Ø | 25 | mm |

| For flat specimens (d x w) | 25 x 25 | mm |

| Specimen dimensions, min. | ||

| Round specimen, Ø | 1 | mm |

| For flat specimens (d x w) | 1 x 1 | mm |

| Accuracy to EN ISO 9513 | Class 0.5 | |

| Weight | 45 / 70 | g |

| Mounted height | 24 | mm |

| Number of sensors | 1 | |

| Type of output signal | Individual signal | |

| Ambient temperature | -50 ... +200 | °C |

| Factory calibration | 21 | °C |

| Description | Value | |

| Type | Strain gauge length 4 | |

| Item No. | 057811 | |

| Accuracy to EN ISO 9513 | Class 0.5 | |

| Factory calibration | 21 | °C |

| Measuring system | Two-sided strain gauge system | |

| Initial gauge length | 20 | mm |

| Modifiable to | 10 | mm |

| Measurement travel | ||

| Tensile | 2 | mm |

| Compression | 1 | mm |

| Specimen dimensions, max. | ||

| Round specimen, Ø | 25 | mm |

| For flat specimens (d x w) | 25 x 25 | mm |

| Specimen dimensions, min. | ||

| Round specimen, Ø | 1 | mm |

| For flat specimens (d x w) | 1 x 1 | mm |

| Mounted height | 24 | mm |

| Number of sensors | 2 | |

| Type of output signal | Mean value | |

| Ambient temperature | -50 ... +200 | °C |

| Weight | 70 | g |

| Description | Value | |

| Type | Strain gauge length 5 | |

| Item No. | 0568931 | |

| Measuring system | Two-sided strain gauge system | |

| Initial gauge length | 10 | mm |

| Modifiable to | - | mm |

| Measurement travel | ||

| Tensile | 1.5 | mm |

| Compression | 1.5 | mm |

| Specimen dimensions, max. | ||

| Round specimen, Ø | 25 | mm |

| For flat specimens (d x w) | 25 x 25 | mm |

| Specimen dimensions, min. | ||

| Round specimen, Ø | 1 | mm |

| For flat specimens (d x w) | 1 x 1 | mm |

| Accuracy to EN ISO 9513 | Class 0.5 | |

| Weight | 70 | g |

| Mounted height | 14 | mm |

| Number of sensors | 2 | |

| Type of output signal | Individual signal | |

| Ambient temperature | -50 ... +200 | °C |

| Factory calibration | 21 | °C |

- USC or DCSC module 2x required

| Type | Clip-on extensometer 2002-2 | |

| Item No. | 10422071 | |

| Measuring system | Two-sided strain gauge system | |

| Initial gauge length | 20 | mm |

| Modifiable to | 10 | mm |

| Measurement travel | ||

| Tensile | 2 | mm |

| Compression | 1 | mm |

| Specimen dimensions, max. | ||

| Round specimen, Ø | 25 | mm |

| For flat specimens (d x w) | 25 x 25 | mm |

| Specimen dimensions, min. | ||

| Round specimen, Ø | 1 | mm |

| For flat specimens (d x w) | 1 x 1 | mm |

| Measurement value resolution | Depends on machine electronics, see machine electronics resolution | |

| Accuracy to EN ISO 9513 | Class 0.5 | |

| Weight | 70 | g |

| Mounted height | 24 | mm |

| Number of sensors | 2 | |

| Type of output signal | Individual signal | |

| Factory calibration | 21 | °C |

| Ambient temperature | -50 ... +200 | °C |

- USC or DCSC module 2x required

Transverse strain extensometer for AllroundLine and zwickiLine testing systems

| Type | Strain gauge width | |

| Item No. | 057813 | |

| Measurement width | 20.5 ... 16.5 (convertible) | mm |

| Measurement travel | 4 | mm |

| Specimen thickness | 0.4 ... 6 (steel) | mm |

| Installation height | 60 | mm |

| Measurement value resolution | Depends on machine electronics, see machine electronics resolution | |

| Accuracy | Class 0.5 | to EN ISO 9513 |

USC or DCSC module required !

| Type | Biax 2501-2 clip-on extensometer | |

| Item No. | 10449601 | |

| Measuring system | double-sided strain-gauge system | |

| Measurement travel | ||

| tensile | 1.2 | mm |

| compression | 0.5 | mm |

| Measurement travel for change in width | ±0.5 | mm |

| Initial gauge length L0 | 25 | mm |

| Specimen dimensions | ||

| round specimen (Ø) | up to 38 | mm |

| flat specimen width, max. | 60 | mm |

| flat specimen thickness, max. | 34 | mm |

| Measured-value resolution | depends on machine electronics, see machine electronics resolution | |

| Accuracy to EN ISO 9513 | ||

| -55 ... +100 °C | Class 0.5 | |

| -70 ... +175 °C | Class 1 | |

| Ambient temperature | -70 ... +175 | °C |

| Overall height | 39 | mm |

| Approx. weight | 200 | g |

| Number of sensors | 3 | |

| Type of output signal (extension) | Mean value | |

| Type of output signal (change in width) | Single signal | |

- 2 x USC module required