videoXtens Array

videoXtens L 3-320, 4-460, 6-680: the extremely versatile extensometer for high resolution in a wide measurement range. Download- 680 mm

- +10°C ... +35°C

- Tensile, compression, flexure tests

- Cyclic tests

- Metals

Patented technology ensures 100% validity of performed tests

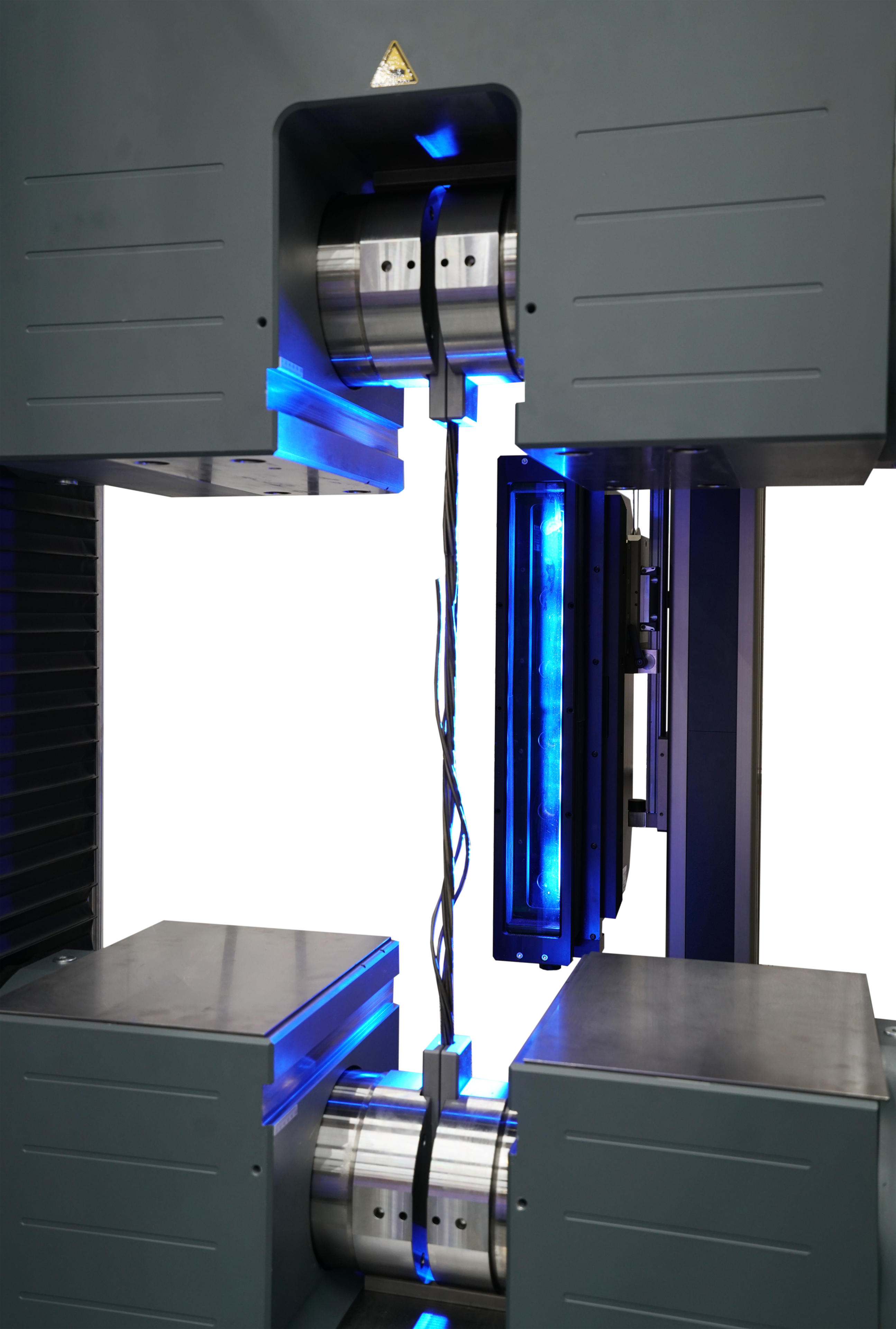

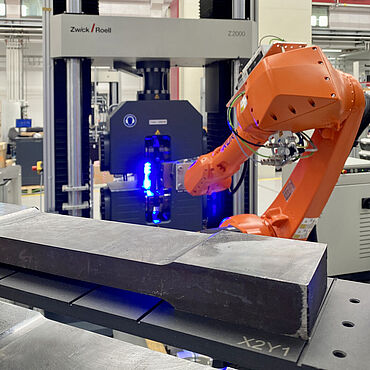

The videoXtens L 3-320, 4-460, 6-680 Array systems provide the highest level of flexibility and accuracy for a wide range of applications. The videoXtens Array series contains an option of three, four or six high-resolution cameras for the measurement of axial extension.

The patented array technology consolidates overlapping fields of view into one large field of view. The combination of the large field of view and the blue contrast light ensures complete illumination of the specimen and detection of the fracture along the entire area of grip-to-grip separation. This allows you to achieve 100% validity of performed tests, even when the fracture lies outside of the original gauge length, which may also be significantly smaller than the grip-to-grip separation.

- 100% validity of performed tests due to the detection of every fracture location.

- Optimal illumination of the entire specimen through integrated blue contrast light.

- Significant time and cost savings through measurement without gauge marks.

- Extremely low wear, especially for high specimen throughput or vigorous specimen breaks.

- Closed loop strain rate control according to ISO 6892-1 method A1

Additional videoXtens advantages & features

Of course, all the general advantages of videoXtens systems also apply to the videoXtens L 3-205 HP/OPC.

Advanced functionality: Simply activate and see more

The testXpert testing software gets even more out of the camera images. Why only set two gauge marks? The video extensometer’s camera(s) capture a large part of the specimen. The testing software also uses this area for other evaluations, from change in width and automatic break detection to 2D digital image correlation.

Change in width measurement / transverse strain measurement

This option is used for biaxial measurements: One or more transverse strain measurements are recorded at the same time as the longitudinal strain measurement, for example the change in width directly at the edge of the specimen, contact-free and without gauge marks. The number of measuring points can be freely selected. The values are automatically averaged, but can also be evaluated individually.

The extension is available as a software-only option or as a hardware extension:

- The software option can be easily extended and meets accuracy class 1 (ISO 9513) for most videoXtens systems.

- For the transverse strain hardware option, an additional camera is integrated directly into the housing of the videoXtens. This camera is specially designed for the change in width and achieves much more accurate measurement values, for example accuracy class 0.5 (ISO 9513).

Strain distribution: every specimen counts

A break outside the gauge length causes costs and additional time for specimen preparation and retesting. This can be prevented with the strain distribution option.

During the test, the testing software automatically places the gauge length symmetrically around the break point.

The workaround offered by ISO 6892-1 in Annex I to validate breaks outside the gauge length is also activated effortlessly by our software; calculation and validation according to standard specifications run automatically and in real time. No need to manually measure and recalculate the specimen as was the case before.

Test Re-Run: re-calculate instead of re-testing

The test re-run function can be used to virtually repeat and recalculate the test with a modified initial gauge length. You save time on specimen preparation and testing and can run different evaluations on one and the same specimen.

During the test, the testing software records the image series. You can later use these to change the size and position of the initial gauge length as required. One click starts the recalculation and all characteristic values are recalculated on the basis of the new gauge length. Each recalculation is displayed separately, making comparisons simple and clear.

2D Digital Image Correlation (DIC)

2D digital image correlation visualizes deformations and strain over the entire visible specimen surface. This software option considerably expands the analysis options of the videoXtens. Activation is very simple, you only need a software license. The live strain measurement and subsequent 2D DIC analysis are performed with the same videoXtens and using the same marker.

A wide range of analysis tools provide different types of information: Gauge lengths, measuring points, virtual strain gauges, cutting lines, vector maps and more. Here you will find detailed information about 2D DIC.

2D dot matrix

Up to 100 measuring points can be set and measured in any arrangement or in the form of a grid. In this way, local strains and inhomogeneities of a specimen under load are determined. X and Y coordinates as well as the distances between dots are available as measured values.

The measured values can be easily exported or displayed as channels directly in testXpert. The prerequisite is that all measuring points are applied to a flat specimen surface, as this is a two-dimensional measurement. Typical applications includes tests on components or multiaxial tensile tests.

Flexure test: deflection measurement

The videoXtens offers different options to measure deflection. A measuring plunger is often placed under the specimen for comparability with measurements using sensors or transducers. The measurement displacement during the test is measured by videoXtens using stick-on gauge marks.

Alternatively, it is also possible to measure directly on the specimen edge: either by applying a mark to the flexure specimen or by using a backlight behind the specimen, which makes the lower edge of the specimen visible and measurable for the videoXtens. In addition to the deflection in the test axis, the polynomial approximation of the curvature can also be determined.