videoXtens T-160 HP Transverse Strain Extensometer

The new standard for r-value measurement Download

Max. measurement range

- 160 mm

Temperature range

- Ambient temperature

Type of test

- Transverse strain measurement

- r-value determination

Material

- Metals

Reliable r-values to ISO 10113:2020 with low scatter, easy handling and many extras

Here is what differentiates the videoXtens T-160 HP from the other optical transverse strain extensometers:

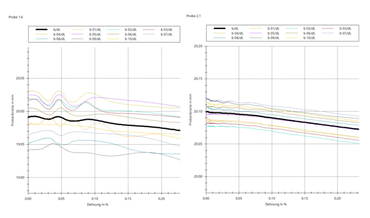

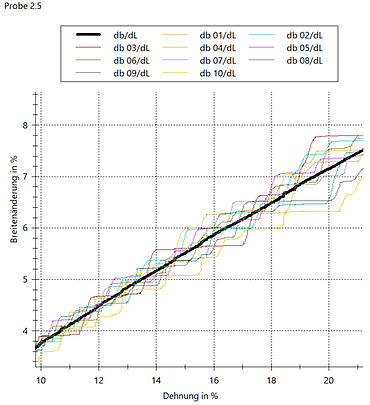

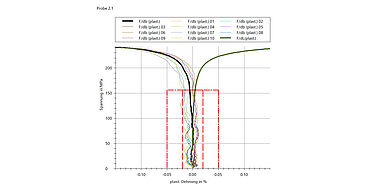

- Measurement of change in width over the entire gauge length according to the recommendation of ISO 10113:2020.

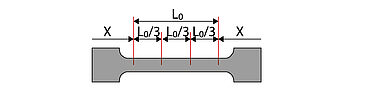

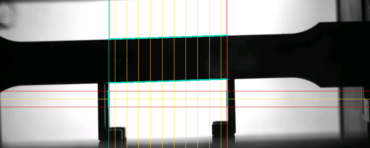

- Automatic axial gauge length detection through the use of offset sensor arms with multiXtens II HP / makroXtens II.

- Uniform distribution of the 10 measurement axes over the entire gauge length. The outer measurement axes run through the measuring points of the gauge length.

- Tracking of the 10 measurement axes during the test; no slipping of the specimen through the measurement axes.

- Automatic detection of the break location and break classification to ISO 6892 or JIS Z2254.

- Very high accuracy (class 0.5 to ISO 9513) through use of a camera and lens specifically selected for the test task.

The new standard for reliable r-values according to ISO 10113, ASTM E517, JIS Z2254

The r-value, or more accurately the vertical anisotropy, is one of the common characteristic values determined from tensile tests in accordance with ISO 10113, ASTM E517 and JIS Z2254. ZwickRoell developed the new videoXtens T-160 HP for this purpose. It measures over 10 measurement axes, equally distributed over the entire measurement range. With that, it not only delivers realistic r-values to ISO 10113, but also precise and highly accurate values.