Load cells

Download- 5 N - 2,500 kN (quasi-static)

- 1 kN - 1,000kN (dynamic)

- ISO 7500-1

- ASTM E4

Load cell comparisons Requirements Advantages & features Accuracy features Optional accessories

In the field of materials testing, a load cell is used to characterize the mechanical properties of a material by measuring the force required to deform or break the material. Load cell sensors convert the physical quantity force into an electrical voltage which can then be measured. Load cells can be used for tensile, compression and flexure tests, as well as torsion and cyclic tests.

Due to the often extreme and diverse requirements in materials testing, the load cell is the heart of the testing system. By nature it provides the prerequisite for reliable, interpretable test results. To ensure that this core component is optimally integrated into the testing system, ZwickRoell has developed and manufactured our own patented Xforce load cell series, which meet the highest requirements in terms of accuracy and robustness.

| Xforce | Precision P | High-precision HP | High-precision HP+ 1 | K | K+ 1 | High-capacity | Dynamic 2 |

|---|---|---|---|---|---|---|---|

| Nominal force Fnom | 5 N to 150 kN | 5 N to 10 kN | 5 N to 10 kN | 10 kN to 250 kN | 10 kN to 250 kN | 330 kN to 2,500 kN | 1 kN to 1,000 kN |

| Accuracy Class 1 from x % of Fnom | 0.4% | 0.2% | 0.1% | 0.2% | 0.1% | From 0.2% of Fnom | From 0.4% of Fnom |

| Accuracy class 0.5 | 2% | 1% | 0.1% | 1% | 0.1% | From 1% of Fnom | From 1% of Fnom |

| Applications | Quasi-static | Quasi-static | Quasi-static | Quasi-static | Quasi-static | Quasi-static | Quasi-static and fatigue tests |

1 The plus load cells feature a wider measurement range in which the calibration is valid.

2 The Xforce dynamic load cell is equipped with an integrated accelerometer (from 5 kN).

How does a load cell work?

The most common industrial load cell is the strain gauge. It works by means of a mechanical deformation element to which strain gauges are attached in the form of a measurement bridge.

When a force is applied to the load cell, the mechanical element to which the strain gauge is attached is elastically deformed. Deformation in the form of mechanical elongation and compression causes the strain gauge to be elongated or compressed. This strain-related (and therefore force-dependent) change in resistance is converted into a measurement signal by the measuring electronics and processed.

A compression load cell measures compression forces and is normally installed below the test fixture. A tension load cell measures tensile forces.

Daily Check device

The Daily Check device is used for regular checks on load cells up to 500 N by means of comparison values which have been measured following recalibration/adjustment. The device consists of two reference standards (master/slave).

- Implementation of the fixtures and software on any number of machines through simple installation and removal.

- Detection of systematic errors in compression and tensile direction in the load cell.

- Reliable test results: Performing checks between periodic calibrations ensures that the load cell transducer is free of systematic errors.

- The results of the daily check are documented in a testXpert report.

- Traceability: All safety-critical tests have specific requirements in terms of traceability and documentation. With our ZwickRoell testing software, the administrator can specify what is to be recorded and for which operations and events justifications must be added.

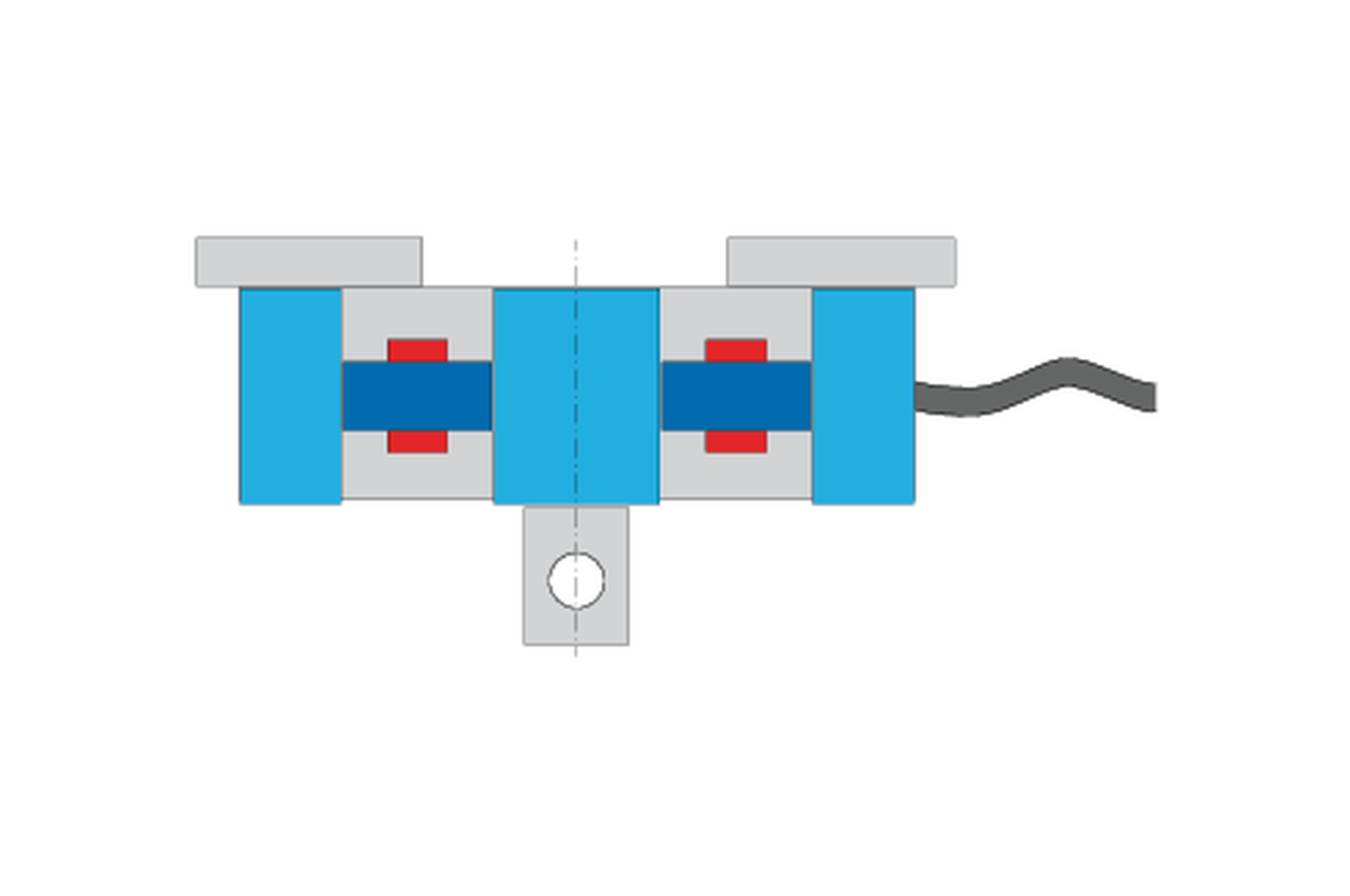

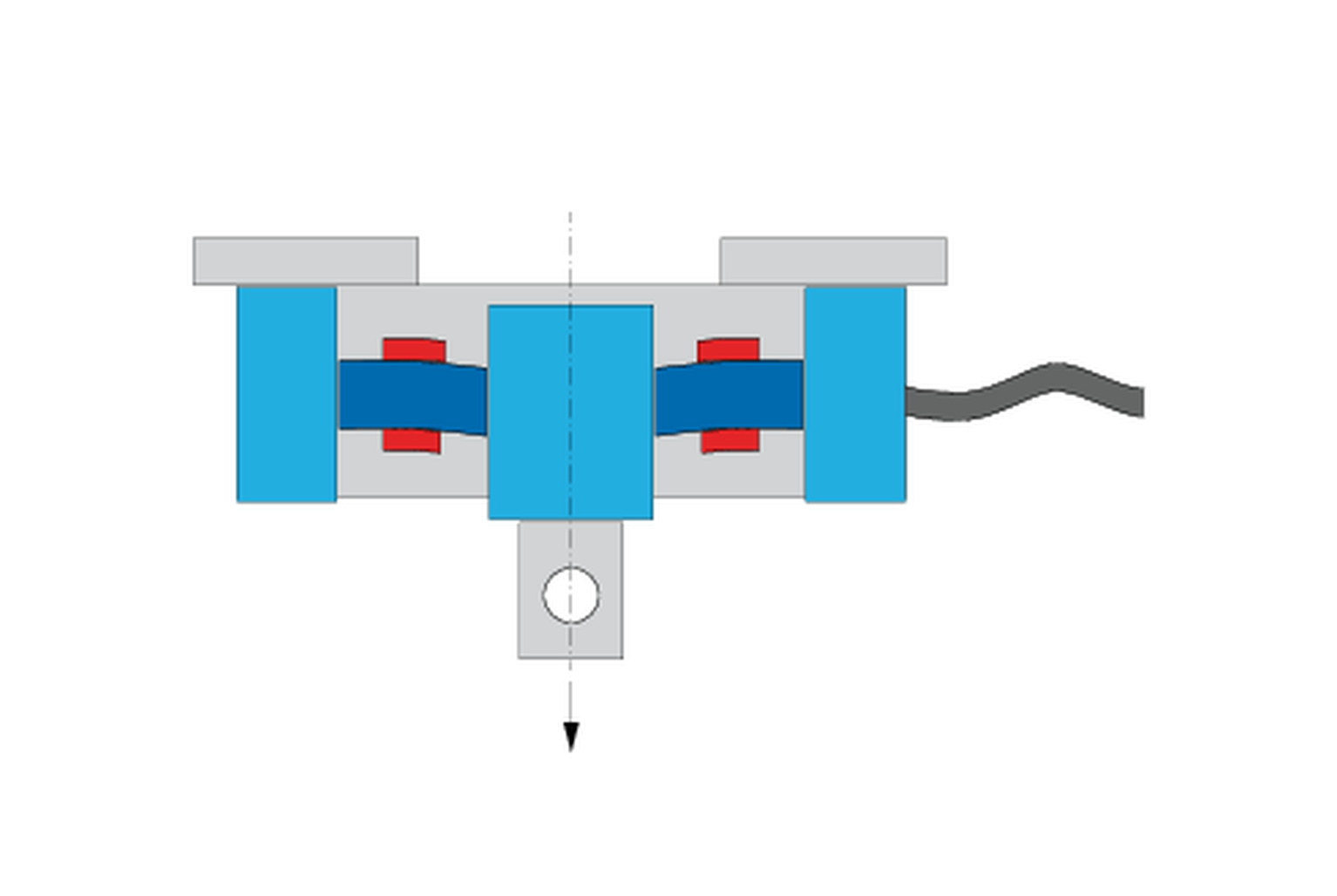

Xforce load measuring system with load bypass unit

Load cells with load bypass unit are particularly suitable when:

- Tests are performed at high test speed, since here there is a possible risk that the set force limits don’t react quickly enough.

- Tests take place with small separation between test tools or with short travel distances; therefore, also particularly well suited for spring and component testing.

For tests in the compression direction, Xforce HP load cells are protected by mechanical overload protection and an integrated load bypass unit.

- In case of mechanical overload protection, a mechanical stop blocks it before reaching the maximum permissible limit force of the load cell. This prevents any damage to the load cell due to overloading.

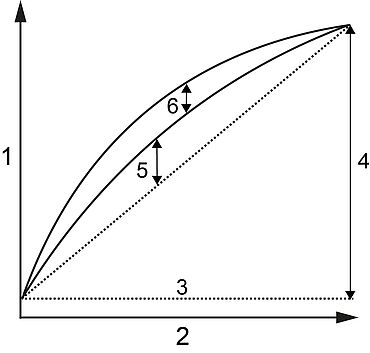

- The integrated load bypass unit protects the entire test arrangement: Starting at force threshold 120+6/-4% Fnom, the existing force is transferred to several springs. As a result, the entire test arrangement bypasses a load. This load bypass prevents a force increase in the load cell that would cause overloading or even destruction.

Downloads for load cells

- Product Information: Xforce K Load Cell PDF 3 MB

- Product Information: Xforce HP Load Cell PDF 6 MB

- Product Information: Xforce HP+ and Xforce K+ Load Cells PDF 3 MB

- Product Information: Xforce P Load Cell PDF 1 MB

- Product Information: Load Cells 330 kN - 2,500 kN PDF 244 KB

- Product Information: Xforce Load Cell, Dynamics PDF 314 KB

- Product Information: Xforce Load Measuring System with Load Bypass Unit PDF 389 KB

- Daily Check PDF 750 KB

Frequently asked questions

A load cell converts forces caused by tension, compression or torsion into an electrical signal that can be measured, read and recorded.

The main component of a load cell is a mechanical deformation element to which strain gauges are attached.

A strain gauge is a sensor that measures deformation caused by a change in electrical resistance. In materials testing, strain gauges are used in load cells.

A load cell is used to measure the force acting on the sensor. They are used to determine compression forces or tensile forces, but are also suitable for dynamic test tasks.