- -80°C to +250°C

- -80°C to +250°C

- -50°C to +180°C

- Up to 250 kN

- Up to 2.5 kN

- Precise temperatures

- Flexible extensometer integration

- Flexible in use

- Can be retrofitted

- Universal

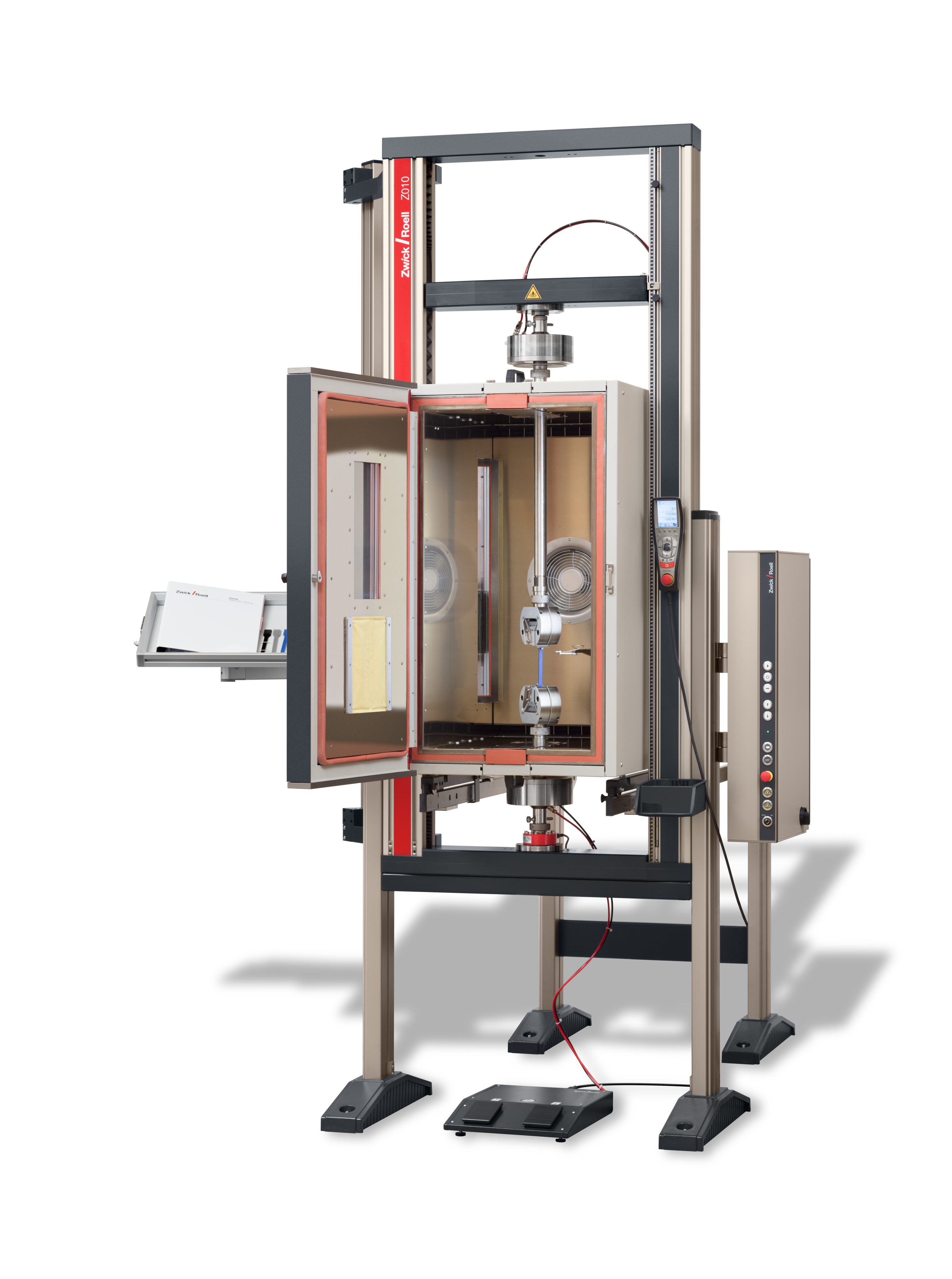

Temperature chambers, also referred to as thermal chambers, are an important component in quality assurance in many industries and play a crucial role in the assessment of quality, reliability and performance of products and materials under temperature conditions. Many standards require tests under temperature. The innovative temperature chambers from ZwickRoell guarantee a flexible testing system, specifically tailored to customer requirements, for materials and component testing in a load range up to 250 kN and a wide temperature range of -80 °C to +360 °C.

Our temperature chamber for temperatures ranging from -50 °C to +180 °C for small loads up to 2.5 kN provides a cost-effective option with a small footprint.

Applications Videos Advantages & features Technical data Optional accessories

| 250 °C AllroundLine temperature chamber | 360 °C AllroundLine temperature chamber | zwickiLine temperature chamber | |

|---|---|---|---|

| Temperature range | -80°C to +250°C | -80°C to +360°C | -50°C to +180°C |

| Load range | Up to 250 kN | Up to 250 kN | Up to 2.5 kN |

| Applications |

| Cost effective option for tensile, compression and flexure tests with low loads and a small footprint | |

| Number of different sizes |

|

|

|

| Extensometer type and arrangement |

|

|

|

| Door-in-door |

|

| ./. |

Applications of the -80 °C to +360 °C temperature chamber

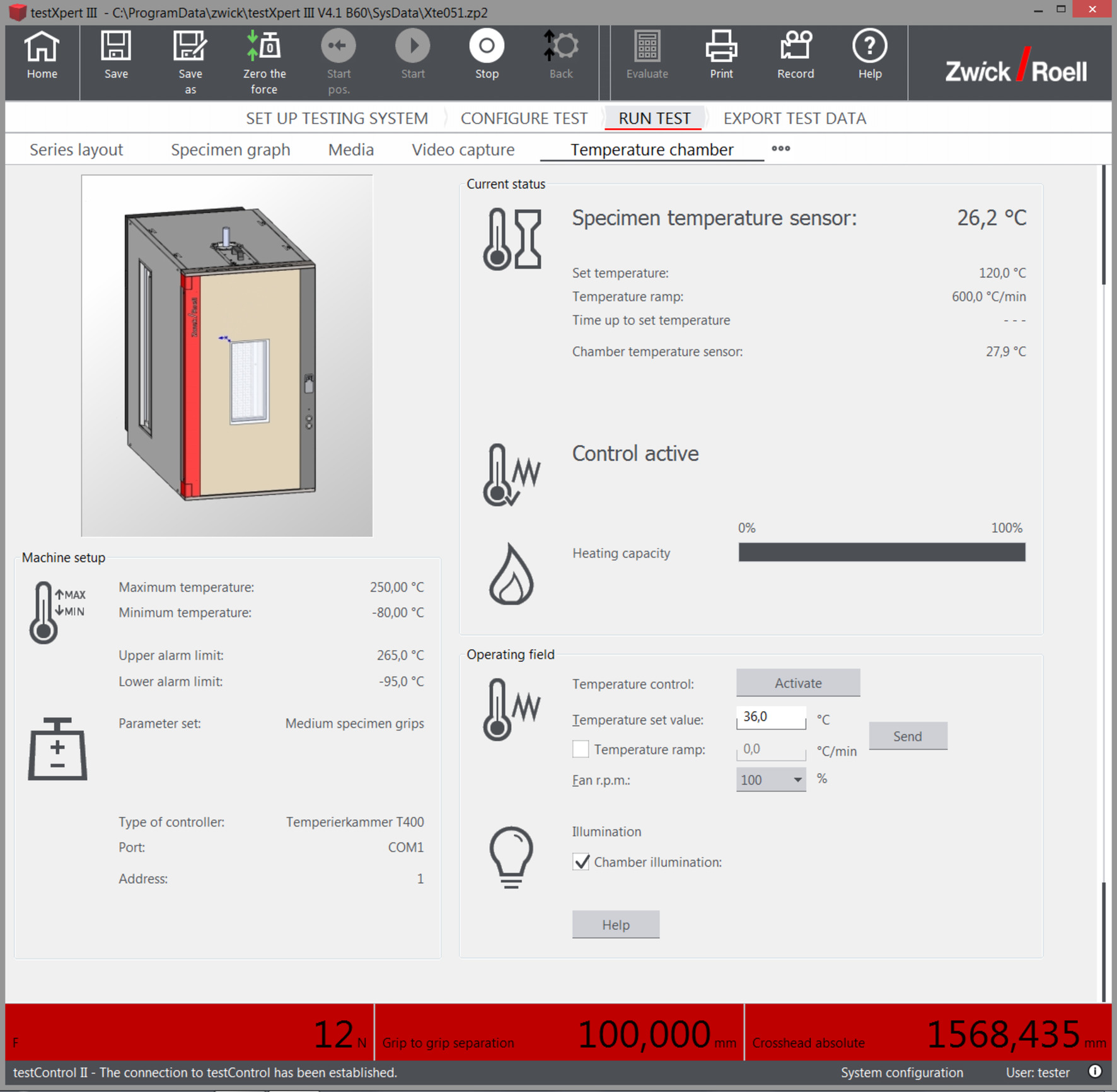

All system components used with the temperature chambers made by ZwickRoell are seamlessly compliant with each other. With the use of our testXpert testing software, operation of all system functions is ergonomic and intuitive. All data can be traceably documented with the test series. The temperature chamber is optimally integrated in the world of ZwickRoell extensometers. Reliable test results are guaranteed for both optical and sensor arm measurements. Our modular design allows optimum adaptation of the chamber to suit your needs. The large volume capacity of the chamber allows additional test area space for components testing.

Our temperature chambers up to +360 °C for the AllroundLine materials testing machine with a load range up to 250 kN are universal chambers that can be used for the following applications:

Applications for standard and engineering plastics

This thermal chamber, including all system components, covers the full temperature range for all standard and engineering plastics. Reliable test results, e.g. to ISO 527-1 and ASTM D638 are therefore guaranteed .

- For example, you can measure plastics with pronounced yield strength with high precision using the videoXtens or the makroXtens and you can switch the crosshead travel measurement completely automatically without opening and closing the door.

- If you need large measurement travel distances for plastics without pronounced yield point, an optical and mechanical version with lightXtens and longstroke extensometer is also available.

Applications for elastomers and rubber

The thermal chamber, including all system components, also covers the full temperature range for rubber and elastomers.

- Large measurement travel distances for elastomers and rubber are handled with the lightXtens or the longstroke extensometer, giving you the flexibility of using optical or sensor arm measurements.

- Standard compliant testing and temperature accuracy are ensured, for example, in accordance with ISO 23529, ISO 37 and ASTM D412.

Applications for composites

The temperature chamber, including all system components, covers the temperature range for most types of composites.

- For composites with PEEK matrix for example, the temperature chamber up to 360 °C is suitable with corresponding specimen grips and tools.

- We offer a comprehensive test tool portfolio for composites testing, which can be flexibly used with the temperature chamber.

Temperature chamber -50 °C to +180 °C up to 2.5 kN

One of our temperature chambers was specially designed for use with a zwickiLine materials testing machine to provide a cost-efficient option for small loads up to 2.5 kN and with a small footprint. You can use it to perform tensile, compression and flexure tests at specified temperatures within a range of -50 °C to +180 °C.

- Cost-efficient temperature chamber with industrial standard Eurotherm controller

- Equipped with RS 232 interface for operation with PC as standard

- Ergonomic, CE-compliant design for simple, safe, and reliable operation

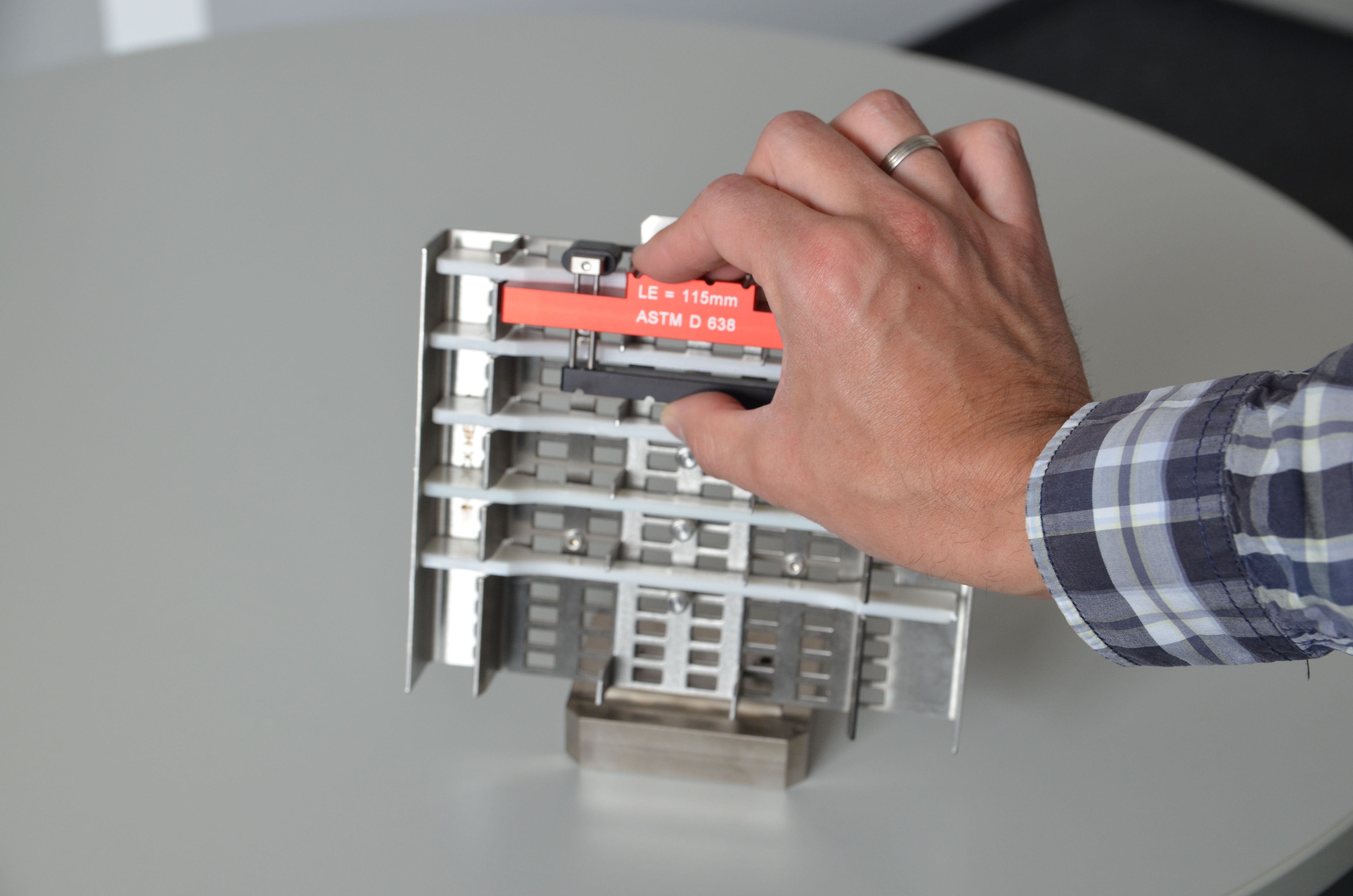

- Flexible use of different clip-on extensometers

- Easy removal of the temperature chamber

Video: Temperature chamber in use

Tensile test on plastics to ISO 527-1

Technical overview of the different temperature versions

| Item No. | 1090458 | |

| Temperature range | RT +10°C ... +360 °C | |

| With LN2 cooling system (option) | -80 ... +360 °C | |

| Connection LN2 (inner threads)1 | G 3/8 | |

| Coolant operating pressure | 1.5 +/- 0.1 | bar |

| Typical LN2 consumption when: 2 | ||

| Cooling from RT to -30 °C | 8.5 | l |

| Hold at -30 °C | 9 | l/h |

| Cooling to -80 °C | 19 | l |

| Hold at -80 °C | 14 | l/h |

| Rate of temperature change without load to EN 60068-3-53 | ||

| Heating mode from RT to 360°C | 11.5 | K/min |

| Corresponds to a warm-up time of: | 23 | min |

| Cooling mode from RT to -80 °C | 5 | K/min |

| Corresponds to a cool-off time of: | 17 | min |

| Temporal instability 4 | +/- 1 | °C |

| Local inhomogeneity 4 | +/- 1 | °C |

| Power supply | 400 | V, 3Ph/N/PE |

| Power frequency | 50/60 | Hz |

| Power consumption | 7.2 | kVA |

| Power supply cable | l = 4 m, with 5-pin CEE plug (16A) | |

| Interface | RS 232 (requires a COM port on the PC) | |

| Minimum version | As of testXpert III V1.6 | |

| Dimensions: | ||

| Test area: | ||

| Height | 900 | mm |

| Width | 460 | mm |

| Depth | 740 | mm |

| Inside of the door to the test axis | 400 | mm |

| Outer (distance to outer sides): | ||

| Height | 1040 | mm |

| Width | 600 | mm |

| Depth | 1345 | mm |

| Weight, approx. (without options) | 230 | kg |

| Design | Four openings (two left, two right), closed with dummy plug by default, for connection of extensometers, for example; door hinge on left; condensation drain included in connection unit | |

| Overall noise level | < 68 | dB(A) |

- The supply line connection also includes a G 3/8"-UNF 3/4"-16 adapter

- Chamber closed, with typical equipment (100 kN specimen grips). During cooling: consumption between 10% and 90% of the temperature range to EN 60068-3-5

- The rate of temperature change is determined between 10 % and 90 % of the specified range to EN 60068-3-5

- To DAkkS/DKD R 5-7 Method C: expanded measurement uncertainty of the temperature measurement system +/- 1.5 K (basic chamber, no load)

| Item No. | 1022207 | 1022208 | 1022209 | 1022210 | 1022211 | |

| Temperature range | RT +10°C ... +250 °C | |||||

| With LN2 cooling system (option) | -80 ... +250 °C | |||||

| Connection LN2 (inner threads)1 | G 3/8 | G 3/8 | G 3/8 | G 3/8 | G 3/8 | |

| Coolant operating pressure | 1.5 +/- 0.1 | 1.5 +/- 0.1 | 1.5 +/- 0.1 | 1.5 +/- 0.1 | 1.5 ± 0.1 | bar |

| Typical LN2 consumption when: 2 | ||||||

| Cooling from RT to -30 °C | 2.5 | 3 | 5 | 6 | 8.5 | l |

| Hold at -30 °C | 5 | 5 | 5.5 | 6 | 9 | l/h |

| Cooling to -80 °C | 6 | 9 | 13 | 14 | 19 | l |

| Hold at -80 °C | 8.5 | 8.5 | 8.5 | 11 | 14 | l/h |

| Rate of temperature change without load to EN 60068-3-53 | ||||||

| Heating mode from RT to 250°C | 12 | 12 | 7.5 | 13 | 9.5 | K/min |

| Corresponds to a warm-up time of: | 15 | 17 | 23 | 14 | 19 | min |

| Cooling mode from RT to -80 °C | 7 | 5.5 | 5 | 4.5 | 5 | K/min |

| Corresponds to a cool-off time of: | 12 | 14 | 16 | 19 | 17 | min |

| Temporal instability 4 | +/- 1 | +/- 1 | +/- 1 | +/- 1 | ± 1 | °C |

| Local inhomogeneity 4 | +/- 1 | +/- 1 | +/- 1 | +/- 1 | ± 1 | °C |

| Power supply | 400 | 400 | 400 | 400 | 400 | V, 3Ph/N/PE |

| Power frequency | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | Hz |

| Power consumption | 3.3 | 3.3 | 3.3 | 5.2 | 5.2 | kVA |

| Power supply cable | l = 4 m, with 5-pin CEE plug (16A) | |||||

| Interface | RS 232 (requires a COM port on the PC) | |||||

| Minimum version | As of testXpert II V3.71 / testXpert III | |||||

| Dimensions: | ||||||

| Test area: | ||||||

| Height | 500 | 700 | 900 | 700 | 900 | mm |

| Width | 260 | 260 | 260 | 460 | 460 | mm |

| Depth | 445 | 445 | 445 | 655 | 655 | mm |

| Inside of the door to the test axis | 230 | 230 | 230 | 340 | 340 | mm |

| Outer (distance to outer sides): | ||||||

| Height | 640 | 840 | 1040 | 840 | 1040 | mm |

| Width | 400 | 400 | 400 | 600 | 600 | mm |

| Depth | 1015 | 1015 | 1015 | 1225 | 1225 | mm |

| Weight, approx. (without options) | 140 | 150 | 160 | 159 | 220 | kg |

| Design | Arrangement of extensometer on the left rear side; door hinge to the left; condensation drain included in connection unit | |||||

| Overall noise level | < 68 | < 68 | < 68 | < 68 | < 68 | dB(A) |

- The supply line connection also includes a G 3/8"-UNF 3/4"-16 adapter

- Chamber closed, with typical equipment (400 mm wide chamber: 10 kN specimen grips, 600 mm wide chamber: 100 kN specimen grips). During cooling: consumption between 10% and 90% of the temperature range to EN 60068-3-5

- The rate of temperature change is determined between 10 % and 90 % of the specified range to EN 60068-3-5

- To DAkkS/DKD R 5-7 Method C: expanded measurement uncertainty of the temperature measurement system +/- 1.5 K (basic chamber, no load)

| Item No. | 1014436 | |

| Design | Door hinge on left, controller installation on left side | |

| Cooling system | LN2 (liquid nitrogen) | |

| Chamber control controller type | Eurotherm | |

| Test temperature | -50 ... +180 | °C |

| Ambient temperature | +10 ... +35 | °C |

| Average heating rate (without loading)1 | 5.5 | °C/min |

| Average cooling rate (without loading)1 | 2.5 | °C/min |

| Dimensions: | ||

| External dimensions: | ||

| Height | 500 | mm |

| Width | 700 | mm |

| Depth | 425 | mm |

| Internal dimensions: | ||

| Height | 350 | mm |

| Width | 250 | mm |

| Depth | 250 | mm |

| Weight | 45 | kg |

| Noise level | 55 | dB(A) |

| Input supply voltage | 230 | V |

| Power consumption | 1.5 | kVA |

| Interface | RS 232 (requires a COM port on the PC) | |

| Included in scope of delivery |

| |

- The specified values for heating and cooling as well as spatial and temporal fluctuations in temperature apply to a closed chamber without accessories.