Testing of elastomer bearings

Elastomer bearings fulfill a range of functions in the chassis. They serve as joints and assist in equalization and vibration isolation and damping. Various test methods can be used to characterize and test active and passive bearings. In the example, a single axis elastomer bearing is characterized.

Testing of the exhaust system

Exhaust systems are highly stressed, complex components that are subject to thermal loads, jolts, and vibrations, as well as corrosive media. These systems include a large number of sensitive components such as catalytic converters, measurement sensors, and electronics, which must be designed and checked for these requirements. ZwickRoell offers a wide range of testing solutions. In the example, biaxial tests are performed on a complete exhaust system in a servo-hydraulic testing system.

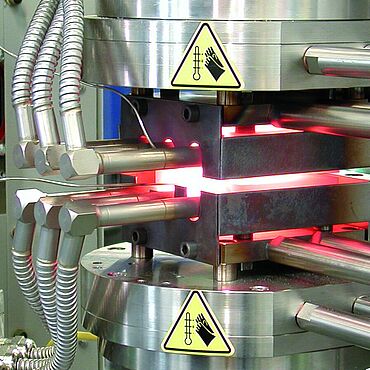

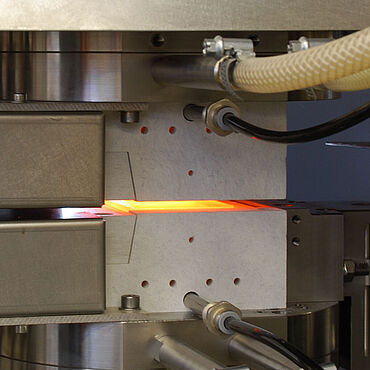

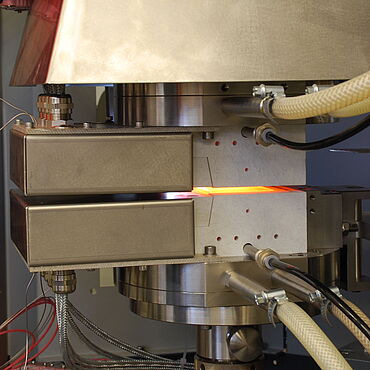

Testing of catalytic converter mats

The aim of this test is to determine the stiffness and friction coefficient of catalytic converter mats under temperature. A testing machine with compression platens that can be heated up to 1050 °C is used. Two layers of the material, separated by a metal sheet, are placed between the compression platens. The compression platens are then heated and the vertical test load is applied. The distance between the compression platens is measured by a laser extensometer with an accuracy of ±5 μm. Using an optional second test axis, the metal sheet can also be moved horizontally between the two layers. The force required for this can be converted into the temperature-specific coefficient of friction.