Materials Testing

Non-destructive and destructive material testing/material testing examines the mechanical strength of a material until it breaks or reaches a certain deformation. The tests can take place under different environmental conditions.

Through material characteristic values materials testing delivers a clear definition of the material properties, which in turn allows for the comparison between different materials.

Materials testing is not only performed at research institutes, it also helps companies obtain valuable knowledge for the development of new products, and the improvement of existing products.

Overview of test types Destructive materials testing Non-destructive materials testing

Testing machines for static tests Testing machines for dynamic tests

Standardized test methods (e.g. by ASTM and ISO) play a central role in mechanical materials testing and component testing and are recognized worldwide to ensure quality and safety in various industries. They provide precise specifications for test procedures, test conditions and test equipment:

Test Methods for Materials Testing

There are a variety of test methods that can be applied in materials testing:

- In (quasi-) static testing or static materials testing loading on the specimen is slow and constant. In static materials testing the strength and deformation behavior of specimens and components, predominantly subjected to tension, compression, and flexure, as well as shearing or torsion, is determined. Static materials testing, relative to dynamic materials testing is performed with lower test speeds.

- For dynamic testing the specimen is subjected to an impact load or the load periodically influences the specimen over a longer period of time. Dynamic materials testing refers to the (destructive) test on materials or components, which is performed with quick movement (dynamic). Examples include pendulum impact testers, drop weight testers, high-speed tests (puncture or high-speed tensile tests).

- Cyclic materials testing/fatigue testing: in cyclic materials testing, loading on the specimen takes place in continuously recurring load cycles. Depending on the machine, these load cycles can be in the form of tensile/compression, pulsating or alternating load in sinusoidal shape, triangle shape, etc.

Destructive Testing

In destructive testing, specimens are machined from a material and tested for mechanical or chemical loads. The specimen is destroyed or altered (on the surface). After the test, the tested component, or material specimen can no longer be used.

Destructive materials testing plays a particularly important role in the automotive and aerospace industries, since material fatigue presents a very high risk factor in these sectors. At the same time, materials and components testing has become indispensable in the medical industry.

In most test methods the specimen is destroyed:

Non-Destructive Testing

In non-destructive testing (NDT), the quality of a specimen is tested without damaging it. In this way it can be ensured that the material quality is high enough for further processing and that it can reliably withstand loads for the long-term.

Non-destructive test methods include:

Parts and Components of a Materials Testing Machine

Fundamentally all materials testing machines have comparable parts and components. Many different components are adapted to the load frame:

Electronics Specimen grips Extensometers Load cells Testing software

Standardized test methods in mechanical materials testing

Materials testing includes a variety of test methods with which the behavior and material characteristics of standard specimen materials or finished parts and components (components testing) under mechanical, thermal or chemical loads are determined. The requirements for the test procedures differ in the various industries and are mainly defined in ISO standards and ASTM standards, but also in industry-specific standards and manufacturers' factory standards.

Here you will find an overview of important standardized test methods in mechanical materials testing and component testing:

| Short description | Standards |

|---|---|

| Hydrogen & metals | KIH test |

|

| Cardboard | Corrugated board | Puncture test |

|

| Composites & plastics | Compression test (end loading) |

|

| Cardboard | Corrugated board | Flat crush test (FCT) |

|

| Medical | Cleanrooms |

|

| Cardboard | Corrugated board | Edge crush test (ECT) |

|

| Paper | Tissue | Tensile test wet |

|

| Paper & cardboard | Wet tensile test |

|

| Metals | Thermomechanical fatigue (TMF) |

|

| Cardboard | Corrugated board | Box crush and stacking crush test |

|

| Paper | Tissue | Tensile test dry |

|

| Construction materials | Glass & roof tile | Flexure test |

|

| Plastics | Films | Tensile test |

|

| Medical Industry | Autoinjectors |

|

| Plastics | Pipes | Ring stiffness / ring flexibility |

|

| Medical | Testing of face masks |

|

| Textiles | Thread, yarn, twine | Tensile tests |

|

| Medical | Luer/Luer lock connection - replaced by ISO 80369 |

|

| Metals | Sheet metal | Cupping test to Erichsen & Olsen |

|

| Plastics | Tensile test |

|

| Metals | Sheet metal | Earing test |

|

| Metals | Sheet metal | Hole expansion test, edge crack sensitivity |

|

| Metals | Tensile test (ambient temperature) |

|

| Paper & cardboard | Tensile test dry |

|

| Paper | Tissue | Burst strength / puncture test |

|

| Plastics | Elastomers | Tensile test |

|

| Compression test with shear loading |

|

| Metals | Tubes | Ring tensile test |

|

| Metals | Tubes | Tube-flattening test |

|

| Hydrogen & metals | Material failure due to hydrogen embrittlement |

|

| Metals | Tubes | Drift-expanding test |

|

| Metals | Specimens | Tensile test |

|

| Plastics | Tensile test |

|

| Hydrogen & metals | Hydrogen embrittlement of steel in coating process |

|

| Composites | Compression test (combined loading) |

|

| Metals | Tubes | Flanging test |

|

| Composites| Notched compression test (OHC, FHC) |

|

| Metals | Tubes | Ring-expanding test |

|

| Metals | Tensile test (elevated temperature) |

|

| Composites | Tensile test |

|

| Composites | Tensile test |

|

| Metals | Tensile test (elevated temperature) |

|

| Plastics | Films | Tensile test |

|

| Plastics | Flexible foam | Collective standard for various tests |

|

| Metals | Tensile test (ambient temperature) |

|

| Plastics | Tensile test at high strain rates (high-speed tensile test) |

|

| Paper & cardboard | Burst test |

|

| Paper | Flat crush resistance / corrugated medium test (CMT) |

|

| Paper & cardboard | Ring crush test (RCT) |

|

| Paper & cardboard | Compressive strength / short clamping test (SCT) |

|

| Paper | Zero-span tensile test |

|

| Paper | Coefficient of friction |

|

| Paper & cardboard | Internal bond test / Z-direction tensile test |

|

| Paper & cardboard | Flexure test (2-point) |

|

| Paper & cardboard | Short-span compressive strength test (S-test) |

|

| Medical | Hip implants | Fatigue testing femoral shaft / finite life fatigue |

|

| Medical | Hip implants | Compression/tensile test modular femoral heads |

|

| Medical | Hip implants | Deformation test method acetabular shell |

|

| Medical | Hip implants | Forces for disassembly of acetabular shell / liner |

|

| Medical | Hip implants | Resistance to torque on femoral head - femoral shaft |

|

| Medical | Hip implants | Force for disassembly taper connection |

|

| Medical | Hip implants | Fatigue strength of ceramic femoral heads |

|

| Medical | Hip implants | Fatigue test metallic femoral stems |

|

| Medical | Knee implants | Fatigue test tibial tray |

|

| Metals | Low cycle fatigue test (LCF) |

|

| Construction materials | Wood | Tensile and flexure test |

|

| Textiles | Straps, belts, ropes, cordage | Tensile tests / adhesion tests |

|

| Metals | Sheet metal | Cupping test, forming limit curve (FLC) |

|

| Metals | Sheet metal | Earing test, Fukui |

|

| Medical | Spinal implants | Static & dynamic test / vertebrectomy model |

|

| Medical | Dental implants | Fatigue test |

|

| Medical | Packaging | Residual seal force (RSF) vial |

|

| Medical | Insulin pens and pen injectors | Quality assurance test |

|

| Metals | Hardness Rockwell |

|

| Metals | Hardness Jominy end quench test (Jominy test) |

|

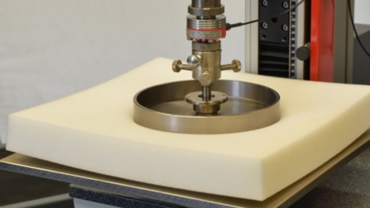

| Plastics | Flexible foam | Compression stress value |

|

| Plastics | Flexible foam | Indentation hardness |

|

| Plastics | Pipes | Creep test |

|

| Plastics | Impact strength Charpy |

|

| Metals | Fatigue test (S-N curve test) |

|

| Textiles | Tests on textile fabrics, coated fabrics, geotextiles |

|

| Metals | Sheet metal | Cupping test, bulge |

|

| Medical | Dental industry | Flexural strength ceramics |

|

| Medical | Catheter | Tensile test |

|

| Composites | Compression after impact (CAI) |

|

| Medical | Medical examination gloves | Tensile test |

|

| Medical | Syringes, prefilled | Test method for assessing integrity and functionality |

|

| Plastics | Impact strength Izod |

|

| Metals | Hardness Vickers |

|

| Plastics | Films | Puncture resistance |

|

| Textiles | Finished products | Tensile tests |

|

| Metals | Sheet metal | Cupping test, VW test |

|

| Plastics | Impact strength Izod |

|

| Plastics | Components | Dynstat test |

|

| Plastics | Flexible foam | Tensile properties |

|

| Plastics | Flexible foam | Tear strength |

|

| Plastics | Impact test, tensile |

|

| Composites | Flexure tests |

|

| Plastics | Pipes | Tensile properties |

|

| Plastics | Puncture test on test plates |

|

| Plastics | 3-point flexure test |

|

| Plastics | 3-point flexure test |

|

| Metals | Hardness Brinell |

|

| Metals | Flexure test |

|

| Medical | Spinal implants | Tests on intervertebral body fusion devices |

|

| Plastics | Films | Coefficient of friction (COF) |

|

| Medical | Stents | Radial compression test |

|

| Medical | Syringes | Plunger glide force |

|

| Metals | Sheet metal | r-value |

|

| Plastics | Flexible foam | Constant-load pounding test |

|

| Plastics | Pipes | Crack growth |

|

| Metals | Sheet metal | n-value |

|

| Plastics | Melt flow test (MFR, MVR) |

|

| Plastics | Melt flow test (MFR, MVR, FRR) |

|

| Metals | Fracture mechanics crack growth da/dN |

|

| Metals | Fracture mechanics critical stress intensity factor K1C |

|

| Metals | Notched specimen impact test Charpy |

|

| Metals | Notched specimen impact test Charpy & Izod |

|

| Metals | Concrete-reinforcing steel | Tensile, flexure and fatigue test |

|

| Metals | Concrete-reinforcing steel | Shear test |

|

| Composites | Interlaminar shear strength (ILSS) |

|

| Metals | Steel strands | Tensile and fatigue test |

|

| Metals | Threaded fasteners | Tensile, test force, impact, hardness and torsion test |

|

| Metals | Nuts | Test force, hardness and widening test |

|

| Metals | Threaded fasteners | Fatigue test |

|

| Metals | Drop weight test |

|

| Metals | Hardness Leeb |

|

| Medical | Luer/Luer lock connection |

|

| Plastics | Films | Coefficient of friction (COF) |

|

| Metals | Hardness surface hardness depth (SHD), effective hardening depth (DS) |

|

| Plastics | Adhesive tape | Peel adhesion / Peel test |

|

| Metals | Hardness nitriding hardness depth (NHD) |

|

| Metals | Hardness case hardness depth (CHD) |

|

| Metals | Hardness Vickers & Knoop |

|

| Plastics | Rigid foam | Compression test |

|

| Composites | Strength of adhesive bonds (lap shear test) |

|

| Medical | Bone plates | Flexural strength |

|

| Plastics | heat deflection temperature |

|

| Composites | Shear test (in plane shear test) |

|

| Medical | Bone screws | Mechanical properties |

|

| Medical | Cannulas & needles | Break resistance |

|

| Plastics | Pipes | Vicat softening temperature |

|

| Plastics| Vicat softening temperature VST |

|

| Composites | Shear test V-notch (Iosipescu & V-notch rail) |

|

| Composites | Energy release rate G |

|

| Composites | G1c Test / DCB Test (Double Cantilever Beam) |

|

| Hardness tests plastics |

|

| Plastics | Pipes | Impact tests |

|

| Plastics | Hardness Shore |

|

| Plastics | IRHD hardness |

|

| Plastics | Creep tests |

|

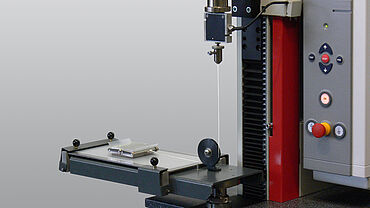

Products for Static Materials Testing

The ZwickRoell Group is the world's leading supplier/manufacturer of testing machines for static materials testing, specially designed for tensile tests, compression tests, flexure tests, shear tests and torsion tests.

Our static materials testing machines are suitable for testing applications in all areas, whether in quality control or research projects, delivering outstanding performance in challenging materials and components testing.