Component Testing

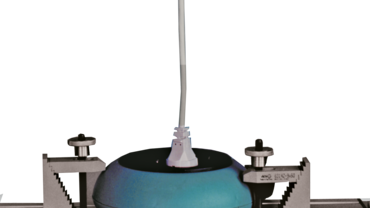

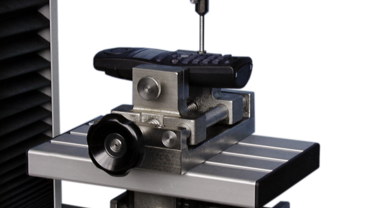

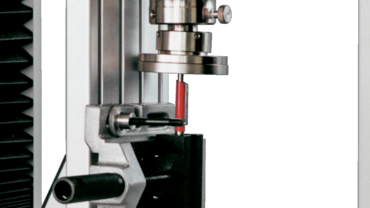

Components testing is one of ZwickRoell’s core competences. In this materials test, finished parts or components are tested for their material properties. The wide field concentrates on quasi-static tests to cyclic tests to dynamic impact tests. We also offer comprehensive tests on your components performed in our own ZwickRoell testing laboratory.

What materials testing methods are available for components testing?

Destructive testing: The examined component is tested for its mechanical material properties and destroyed in the process. This component can then no longer be used. Therefore, this is a destructive materials test.

Non-destructive testing With this method, the quality of a component is tested without damaging or destroying it in the process.

What is the goal of components testing?

- Determination of properties of the components to be tested, e.g. deformation, material, strength, hardness,...

- Quality control of components, e.g. examination of defects on components such as cracks, inclusions, etc.

- Determination of the cause of damage, e.g. why the fracture occurs to the specimen

Components testing under different loads

Components testing under static load: During these tests, the stressability of components is determined.

Components testing under dynamic load: A component is subjected to an impact over a longer period of time.

Components testing under cyclic load: A component is tested with recurring load cycles.