High Cycle Fatigue Test (S-N Test) to DIN 50100, ASTM E466-15, ISO 1099

In the high cycle fatigue test (also S-N test) to DIN 50100 / ASTM E466-15 / ISO 1099, a material or component is stressed with a periodically changing (cyclic) load. ASTM D3479 describes the test on composites.

The high cycle fatigue test is used for the determination of finite life fatigue strength and high cycle fatigue strength for tensile, compression, flexure and torsion loading. Especially in the case of components, the high cycle fatigue test can determine weak points which can then be eliminated through construction or material alterations. Low cycle fatigue strength is not considered in high cycle fatigue testing—it is determined in the low cycle fatigue test.

In the high cycle fatigue test, the load amplitude and the mean load are constant during the single-stage fatigue test. Depending on the magnitude of the load amplitude, it can be applied with varying frequency before the specimen fails.

Test performance S-N curve Finite life fatigue curve Testing machines Other tests

Performing the High Cycle Fatigue Test to DIN 50100 / ASTM E466-15 / ISO 1099

In a high cycle fatigue test the finite life fatigue strength and high cycle fatigue strength of materials or components are determined. For this a number of specimens are cyclically loaded.

- The S-N test is run until a defined failure of the specimen (break, crack) occurs.

- For this test, a particular number of cycles (threshold number of cycles) is defined. If the specimen reaches this threshold number of cycles without recognizable failure, it is considered to be durable or referred to as runout specimen.

Mean, high and low stresses of the cyclic loading are constant for every high cycle fatigue test. For tests on the same S-N curve either only the mean stress, or only the ratio between high and low stress is changed.

S-N curve (Woehler curve)

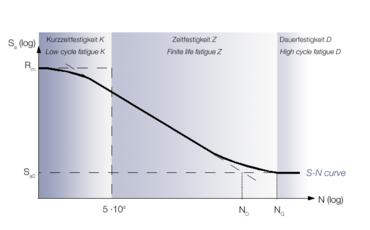

Measured values of cyclic stress amplitude and number of cycles determined in several high cycle fatigue tests result in the S-N curve.

From the S-N diagram you can read the maximum number of load changes for a certain load amplitude.

The S-N curve is divided into three regions:

- Low cycle fatigue LCF K: high load amplitude induces plastic strain on the specimen and causes it to fail after a low number of cycles. The area of low cycle fatigue is not covered in the DIN 50100 standard.

- High cycle fatigue HCF Z: depending on the magnitude of the load amplitude, the specimen can only sustain a certain number of cycles.

- Very high cycle fatigue VHCF D: depending on the load amplitude, breaks as well as runouts will occur.

Finite life fatigue curve

In double-logarithmic representation, the finite life fatigue range of the S-N curve is nearly straight. This straight line is also called finite life fatigue curve.

The position and slope of finite life fatigue curves depend on a number of influences:

- Material

- Specimen Geometry

- Type of loading

- Production conditions

- Thermal treatment

- Surface roughness

Products for the High Cycle Fatigue Test to DIN 50100 / ASTM E466-15 / ISO 1099

To generate the load amplitudes required for high cycle fatigue tests, different testing machines can be used. The testing machine must be capable of compensating for adjustments or changes in the stiffness of the specimen or test arrangement.