Hardness testing and hardness testing methods

Around 1900, Martens proposed the following definition for hardness testing: “Hardness is the resistance of a body to the indentation by another (harder) body.” This simple but precise definition has taken its place in technical circles, and is just as valid today as it was then. Technical hardness is a mechanical characteristic used to describe a material or the state of a material.

Hardness cannot be measured directly, but is derived from primary measured variables (for example test load, indentation depth, indentation area). Depending on the test method, the hardness value is determined from one of the following:

- Test load and one of the geometric values characterizing the hardness indentation (e.g. indentation depth)

- Solely via a length characterizing the indentation

- Through a different material response (e.g. scratch resistance)

Hardness definition What does hardness depend on? Measuring hardness Objective of hardness testing Overview of hardness test methods Static & dynamic hardness test methods Common standards Categorization of load ranges Variations of load applications History

Detailed information on:

Hardness definition

Hardness is the mechanical resistance of a material (specimen) to mechanical indentation by another harder body (indenter).

The hardest natural material is the diamond, which is used for the indenter (industrial diamond).

The definition of hardness differs from the definition of strength, which is the resistance of a material to deformation and separation.

What does hardness depend on?

Hardness is not a fundamental physical property of a material. There are, however, hardness ranges in which certain materials move. Hardness can be changed by heat, meaning that a workpiece takes on a different (higher) hardness value after undergoing a heat treatment.

There are no clearly defined values for hardness. The hardness value determined in a hardness test, can depend on:

- The selected test method

- The test load applied to the indenter

- The length of time the indenter is in the material

- The indenter geometry

- The geometry of the workpiece

How is hardness measured?

Methods with static force application are predominant for hardness tests on metals. Measurements are either taken on the indentation depth or indentation size left behind by the indenter. For static methods in hardness testing, a differentiation is made between depth measurement methods and optical measurement methods.

- Depth measurement methods measure the residual indentation depth of the indenter. The Rockwell method is the only standardized depth measurement method (see ISO 6508, ASTM E18). Besides these, there are non-standardized depth measurement methods: Brinell and Vickers for depth (HBT, HVT).

- Optical measurement methods measure the residual indentation size of the indenter. Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384).

- Alternatively, methods with dynamic force application can also be used within the scope of hardness testing. These include, for example, the Leeb rebound hardness test method / Leeb hardness test (ISO 16589, ASTM A965), which measures the rebound height of a ball indenter.

Hardness testing objective

Hardness testing within the realm of materials testing

- Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals.

- On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion resistance).

- On the other hand, hardness testing is a comparatively easy and fast method to perform; it causes relatively little destruction, that is, only minor superficial damage remains on the specimen surface.

- It also provides a quality control option (incoming and outgoing goods inspection). A wide range of specimen geometries can also be tested using the hardness testing method.

Hardness testing tasks and objectives

- Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the framework of fundamental research (materials science, materials engineering, material diagnostics).

- It is used to determine characteristic values (hardness values), which are critical for use of the material in industrial applications (suitability of a material for a technically relevant component), their acceptance in control processes within the scope of quality assurance (incoming and outgoing goods inspection), for the differentiation of materials (e.g., mix ups of materials) and for the clarification of damage situations (damage analysis).

Hardness test methods overview

| Hardness test method | |||

| Static force application | Dynamic force application | ||

| An indenter with a hard metal ball or a cone/diamond pyramid is pressed vertically into the surface of the test specimen resting on a solid support. The test load is applied impact-free with a defined application and exposure time. | Methods with dynamic force application are predominantly used for hardness tests on large components. | ||

Optical measurement of the indentation The indentation is measured after the work load is removed. The length measurement values (diagonals, diameter) are used to calculate the hardness value. | Depth measurement method The indentation depth is measured under test load or after removal of the additional test load. | Energy measurement The impact and rebound speed (or height) are measured. | |

Measurement under constant test load

| Measurement under preload after removal of the

|

| |

Differentiating between static and dynamic hardness test methods

In principle, the hardness testing methods commonly used in the technology field are divided into methods with static and dynamic force application.

- For static methods, which are predominantly used for hardness tests on metals, the test load is slowly increased. This means that it is applied smoothly, without abrupt movements, for a minimum amount of time specified in one of the standards (see graph).

- For dynamic methods, on the other hand, the test load is applied abruptly, subjecting the specimen to an impact load.

Differentiation criteria for static hardness test methods on metals

Hardness tests on metals predominantly apply methods with static force application. These can be differentiated according to the following criteria:

- Shape of the indenter (spherical, pyramid or cone)

- Material of the indenter (hardened steel, hard metal or diamond)

- Size of the test load applied to a specimen

- Type of evaluation: Measurement of the indentation depth (depth measurement method) or the indentation size (optical measurement method) that is created by the indenter.

Common standards for hardness testing

Hardness tests on metals are performed according to the following common static methods, which are defined in the standards (ISO vs. ASTM) listed below:

| TEST METHOD | ISO | ASTM |

| Brinell | ISO 6506 | ASTM E10 |

| Vickers | ISO 6507 | ASTM E92, ASTM E384 |

| Rockwell | ISO 6508 DIN 50103 | ASTM E18 |

| Jominy test / Jominy end quench test in the Rockwell method | ISO 642 | ASTM A255 |

| Knoop | ISO 4545 | ASTM E92, ASTM E384 |

| Leeb hardness test (rebound hardness test method) | ISO 16589 | ASTM A965 |

The following methods are used for hardness tests on rubber-elastic polymers and elastomers:

| Shore | ISO 7619-1 | ASTM D2240 |

| Ball indentation hardness | ISO 2039-1 | |

| Rockwell | ISO 2039-2 | ASTM D785 |

| Instrumented hardness testing | ISO 19278 (draft) |

Categorization of hardness tests according to load ranges

In the field of hardness testing, different main loads (test forces) are used based on the application. Depending on how high the main load is that is applied to a specimen during the hardness test, within ISO a differentiation is made between micro, low-load or macro hardness testing.

- In the macro range (conventional hardness range), tests are performed using large test loads ≥ 5 kgf, which also lead to correspondingly large hardness indentations on the test pieces. Hardness test methods in the macro range include Brinell, Vickers and Rockwell.

- Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small parts, thick coatings and materials with low hardness.

- Small test loads < 0.2 kgf that create small indents on the test pieces are used for micro hardness tests (most commonly used method: Vickers). Therefore, hardness tests in the micro range can be used to determine the hardness of thin coatings or, for example, the hardness of individual crystallites or inclusions.

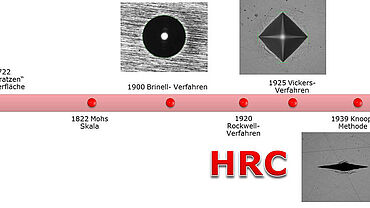

The history of hardness testing

- 1722: R. A. Réaumur develops a method of scratching the surface of minerals using steel.

- 1822: The Mohs scale for mineral testing is invented. This is a ten-point scratch hardness scale in which each material can be scratched using the next harder material. The Mohs hardness values

- are still used today in mineralogy, but are not suitable for determining the hardness of technical materials (metals). The individual hardness steps are relatively large and have different intervals.

| Mohs hardness | Type of mineral | Vickers hardness (HV) |

1 | Talcum | 2 HV |

2 | Gypsum | 35 HV |

3 | Calcite | 100 HV |

4 | Fluorspar | 200 HV |

5 | Apatite | 540 HV |

6 | Orthoclase | 800 HV |

7 | Quartz | 1100 HV |

8 | Topaz | 1400 HV |

9 | Corundum | 2000 HV |

10 | Diamond | 10000 HV |

- 1900: J. A. Brinell develops a ball indentation test that later becomes known as the Brinell method.

- 1920: S. R. Rockwell develops the pre-load method named after him for testing his ships.

- 1925: The Vickers method was invented by R. Smith and G. Sandland in England. It allows micro hardness tests to be carried out.

- 1939: F. Knoop, C. G. Peters and W. B. E. Emerson develop the Knoop method at the National Bureau of Standards (USA).