Cupping Test to Erichsen (ISO 20482) and Olsen (ASTM E643)

The ISO 20482 standard describes the cupping test to Erichsen and is used to determine the ductility of metal sheets and strips. The test is also standardized in ASTM E643 as cupping test to Olsen. An additional description can be found in the Japanese standard JIS Z-224.

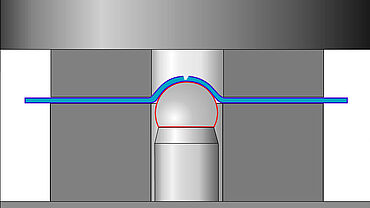

The forming process used for this test essentially records the stretching capacity of the metal material, directly comparable with a stretch-forming and bulge removal process. The edge zones (borders) are held, and therefore are not affected, or only slightly affected, by forming. The specimen is pulled until a crack occurs that runs the full thickness of the specimen, and is just wide enough to allow light to pass through part of its length.

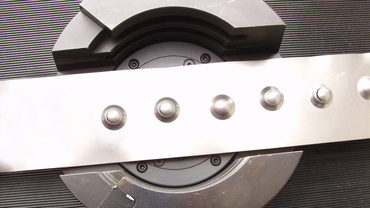

The cupping test for determination of the indentation depth and the force

With the cupping test to Erichsen/Olsen, the indentation depth of a die, as well as the force at the moment of tear are determined. The measured depth of the measurement, which corresponds to the die travel until crack, is the result of the test. At least three tests are performed, and the average value h is indicated in millimeters.

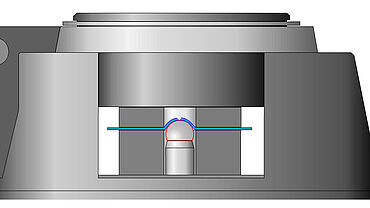

The image is a schematic representation of the cupping test to ISO 20482 / ASTM E643. The specimen (blue) is held with the upper and lower matrix (gray). The die (red) deforms the specimen until a crack occurs.