Biaxial testing of biomaterials

For adequate modeling, the biomechanical behavior and the underlying microstructure of soft biological tissues must first be accurately determined. As most of the tissues in the body are subjected to multi-axial loads, a test machine that applies multi-axis loads to the tissue is required.

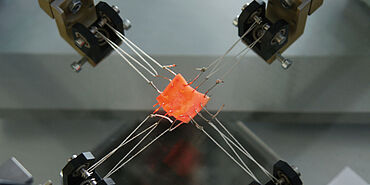

As a result, ZwickRoell has developed a biaxial testing machine that is specifically designed for the mechanical characterization of soft biological and artificial materials. Four linear drives, controlled independently of each other in terms of position, force, or strain, are integrated in the system. Force measurement is via (waterproof) load cells, two each in the X and Y directions. In addition there are four testControl measurement and control electronics units plus a bath for optimum temperature control of the medium. The maximum test load is 100 N per load cell, with resolution up to 0.6 mN. Travel range for tensile measurement is 50 mm (resolution 0.1 μm) and maximum speed is 2,000 mm/min.

In addition to clamping fixtures, the specimens can also be connected to the load cells with a rotatable clamping fixture via hook and cord. This fixture creates homogeneous force application in the specimen and thus, a homogeneous force distribution in the specimen. An additional benefit offered by the new testing machine is the laser speckle extensometer, which enables non-contact two-dimensional strain and deformation measurement without specimen marking. The measuring principle is based on evaluation of speckle patterns formed on the specimen surface by illumination with a laser; these are reflected and recorded with a camera.

The natural biomaterial specimen is first tested in the lab. The data is then represented in a mathematical model and finally transferred to a computer model. Based on the material characteristics, which can be determined with the biaxial testing machine, the virtual reconstruction of the heart wall can be traced and the predictability of the (pathological) behavior of the heart wall can be examined.

Alternative testing solution

An additional biaxial testing machine consists of four electromechanical testing actuators, each with 1 kN load capacity and 200 mm travel. The extension of the specimen is recorded with a laserXtens/videoXtens extensometer. The water bath is equipped with a temperature control unit.

Triaxial testing on biomaterials and tissues

To determine shear properties of soft biological (orthotropic) tissue, a testing system for triaxial applications was developed and designed. The testing machine consists of two main components:

An upper platform, which is designed to be vertically (in the Z direction) displaceable and a lower platform, which is designed to be horizontally displaceable in two directions perpendicular to each other (the X and Y directions). The tissue specimen is connected to the upper and lower platform with a thin layer of super glue during the test and submerged in a suitable physiological and tempered solution. The lower platform moves relative to the horizontally fixed upper platform, whereby the specimen is sheared. The resulting forces in the three orthogonal directions (X, Y, and Z direction) can be simultaneously measured with a special load cell mounted to the upper platform.

The travel distance of the X and Y linear drives perpendicular to each other is ±14 mm (drive travel solution 0.25 μm) with a maximum speed of 3,000 mm/min. The maximum test load of the 3-axis force sensor in the three directions is 2 N each and the measurement accuracy is determined within 0.5% of the measured value. The crosstalk behavior of the force sensor between the X and Y direction is specified at more than 0.5% of the end value and between X/Y and Z at more than 1% of the end value.

Interesting customer projects

- Medical

- 50 N - 200 N

- Uniaxial

- Biaxial