Testing of intervertebral body fusion devices to ASTM F2077

- ASTM F2077 describes a number of different quasistatic and oscillating tests to provide a mechanical comparison of intervertebral body fusion devices. These include shear, compression and torsion tests, which provide a simplified in vivo simulation of the loads imposed on such components.

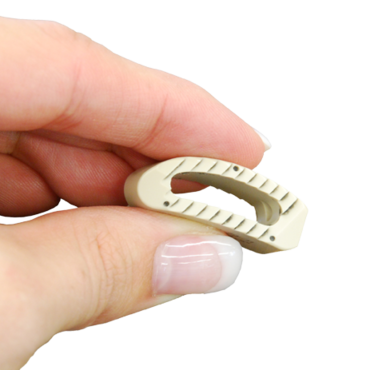

- The intervertebral body fusion device is loaded between two plastic (oscillating test) or metal (quasistatic test) blocks. These are adapted to the outer contour of the intervertebral body. ZwickRoell offers the fixtures required for testing to ASTM F2077 with the corresponding interfaces. Upon request and based on your data, ZwickRoell can design custom blocks for you.

- All tests can also be performed under physiological (in vivo) conditions by using the ZwickRoell thermoregulation bath at 37 °C ±2 °C. The ZwickRoell thermoregulation bath is constructed with DURAN glass and is therefore suitable for almost all biological and chemical test mediums, such as blood, saline solutions, serum, etc.

- It completely satisfies the requirements of standard ASTM F2077 – Characterization and fatigue testing of intervertebral body fusion devices, and is extremely easy to operate.

- These tests can be implemented under physiological environmental conditions (for example, temperature-conditioned saline solution) with use of the ZwickRoell temperature conditioning vessel.

- Head and foot flange assembly for simple and durable installation, taking into consideration the necessary degrees of freedom for the test.

- The test fixture is also suitable for subsidence tests to ASTM F2267.

- Corrosion-resistant container, suitable for disinfection in autoclaves (up to 120 °C).

Torsion tests on intervertebral body fusion devices to ASTM F2077 and ASTM F1717 (static & dynamic)

- As a result of comminuted fractures of an intervertebral body or tumors in the area of the spinal column, it may be necessary to replace an intervertebral body with an implant. These intervertebral body implants are tested by carrying out quasi-static and oscillating torsion tests in accordance with ASTM F2077 and ASTM F1717.

- With the help of a torsion fixture, a rotational movement and thus a torsion load up to 50 Nm is possible via the linear movement of the single testing actuator. The torsion fixture also applies one more axial load, which is defined by variable dead weights and a lever mechanism.

- The main advantage of the ZwickRoell torsion fixture is its ability to test multiple axes with a single closed loop controlled linear actuator. The fixture is designed for static and alternating torsion tests. The angle of rotation for static tests is a maximum of 120° and a maximum of ±20° for oscillating tests.

- With the play-free guide rails, specimens of different lengths can be gripped and tested according to ASTM F2077 and ASTM F1717.