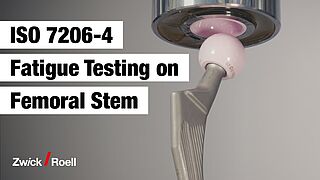

ISO 7206-4, ISO 7206-6: Fatigue testing of femoral stem and femoral neck

The standards ISO 7206-4 and ISO 7206-6 describe the endurance properties test/fatigue teston the stem and neck region of the stemmed femoral components of hip endoprostheses. For the test, the hip endoprosthesis is cemented into a corresponding test fixture and cyclically loaded by means of a dynamic testing machine. The embedment as well as the oscillating load and the number of cycles differ depending on the design and length of the hip endoprosthesis and the part of the standard to be tested.

In the ISO 7206-4 standard, the dynamic load on the hip endoprostheses stem while walking with an implant that is already loosening is simulated in the proximal bone bed in order to test the stem life expectancy. ISO 7206-4 specifies the cyclic load and number of cycles to determine the endurance properties of the femoral stem. A minimum of six femoral stems must withstand five million load cycles at a maximum load of 2300 N and a minimum load of 300 N.

ISO 7206-6 is used to determine thefinite life fatiguein the femoral neck area. This test simulates a well ingrown femoral stem. According to the standard, at least six femoral stems must withstand ten million load cycles with a load of 5.34 kN (R=0.1)

Running a test and test equipment Downloads Request a consultation Additional tests on hip implants

Testing to ISO 7206-4 and ISO 7206-6 with ZwickRoell

- The test test to ISO 7206-4 and ISO 7206-6 can be performed with a servohydraulic testing machine or an LTM electrodynamic testing machine. In addition to the standard requirements, higher cycle loads and number of cycles can also be carried out with these testing systems.

- The mechanical general requirements defined in the standard, including the orientation of the hip endoprosthesis to the test load, the embedding height and the load-application angle, can be accurately defined by means of a ZwickRoell embedding device.

- The specially developed test fixture from ZwickRoell makes it possible to test according to ISO 7206-4 and ISO 7206-6. The compensating bearing ensures a purely axial load on the femoral stem.

- The ZwickRoell testing software testXpert R allows you to run user-friendly progressive load tests (Locati tests).

- The test can also be performed under physiological ambient conditions (e.g. temperature-controlled saline solution at 37 °C) using a ZwickRoell medium container. This is especially necessary if the hip implant has conical taper connections in the stem or neck area.

- This enables you to perform a corrosion test to ASTM F1875, which tests a modular junction's resistance to crevice corrosion and fretting corrosion under dynamic load.