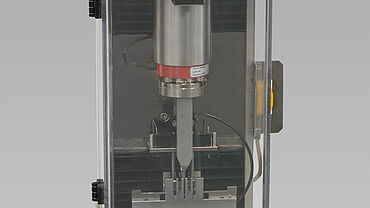

3-/4-point flexure test kit

- The test kit is designed for flexure tests on ceramics to EN 843-1, specimen shapes A and B, and ISO 6872. The base of the test kit is a guide frame equipped with a safety device, in which the corresponding flexure tables and dies required for the test are installed. The necessary load cell is integrated permanently in the guide frame by the factory.

- The linear guide in the guide frame ensures exact alignment between the flexure table and the die. This makes mounting and dismantling of the test kit easy, since realignment is not necessary. The anvils offer the degree of motion required by the test standards, ensuring that the specimen is loaded in the most ideal way possible. Support rollers made of hard metal ensure minimal deformation at the support points.

- A suitable measuring transducer is available for determining the flexural elasticity modulus.

Traceable, tamper-proof test results in accordance with FDA 21 CFR Part 11

Traceable tamper-proof test results

- Ever-increasing demands are placed on software used in the medical and pharmaceutical industries to document the traceability of completed actions.

- With the traceability option, testXpert III enables logging of all actions and changes before, during and after the test, making test results and the documentation traceable and protecting them from manipulation.

- Integrated user management and functions such as electronic records and electronic signature ensure that test results are always protected from tampering.

- Together with the organizational measures and procedure instructions that apply to the individual companies themselves, the requirements of FDA in 21 CFR Part 11 are fulfilled.

- ZwickRoell also offers a qualification service package (DQ/IQ/OQ) for validation support.

- testXpert III logs all test and system related actions and settings and can therefore always answer the question “When does who do what, why and who is responsible?”

Learn more about the testXpert III

Traceability option.