Autoinjector Spring Simulation

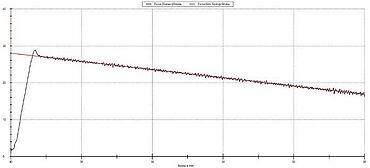

Simulation and characterization of spring forces and syringe glide forces

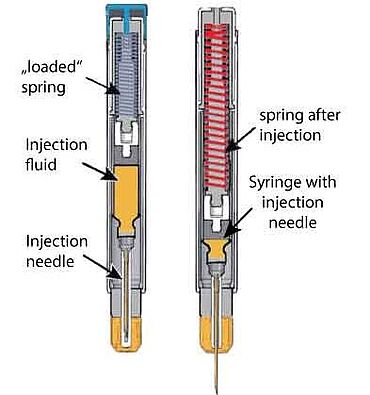

Spring forces have a significant influence on the success of injections using an autoinjector. They must therefore be measured accurately and the syringe systems used must be subjected to different spring loads. This can be done using force-controlled simulation of a spring curve in a ZwickRoell materials testing machine.

These tests can be used at an early stage in the development of an autoinjector and in prospective aging tests.

Why is autoinjector spring simulation important?

- With the simulation of spring forces, the costly use of real springs during development of autoinjectors can be eliminated, and development efforts can be reduced.

- The functional capability of spring loaded autoinjectors, even with changes in viscosity during storage, can already be tested in the development phase. This ensures product safety and helps avoid possible recalls due to incomplete injections.

- Through the simulation of autoinjector spring characteristics, development costs can be reduced.

Autoinjector spring simulation with ZwickRoell

- Spring forces can be simulated with a ZwickRoell zwickiLine materials testing machine or with a 1 kN electromechanical servo testing actuator. Depending on the required injection speed, a powerful wear-free AC motor enables a high crosshead speed of 30,000 mm/min over the entire force range up to 1 kN.

- The high resolution of the crosshead movement and excellent speed accuracy, even at very slow test speeds and short test travel, deliver reliable test results

- An optional temperature chamber allows for the simulation of spring forces under temperature.

- The ZwickRoell test fixture for syringes and carpules can be used to perform the test.

- The testXpert III test program enables the free creation of graphical test sequences. Tests can be created and modified within a very short time.