DIN EN ISO 898-2 / ASTM F606-2 / DIN EN ISO 3506-2: Testing of nuts / washers

Testing of nuts is used to determine mechanical properties to DIN EN ISO 898-2, ASTM F606-2, DIN EN ISO 3506-2.

In addition to screws, nuts / washers are also universally considered important fasteners and must therefore be strictly controlled. They are used in construction of machinery and equipment, as well as vehicles and buildings. Since mechanical stress is concentrated on these types of connection points, the integrity of screws and nuts is extremely important, which also makes them subject to strict safety requirements.

Standards Property classes Proof load test Hardness test Widening test Testing machines Metals brochures

Additional standards for testing of nuts / washers

- DIN EN ISO 898-2 - Mechanical properties of fasteners made of carbon steel and alloy steel – Part 2: Nuts with specified property classes – Coarse thread and fine pitch thread

- ASTM F606-2 – Standard Test Methods For Determining The Mechanical Properties of Externally And Internally Threaded Fasteners, Washers, And Rivets

- DIN EN ISO 3506-2 – Mechanical properties of corrosion-resistant stainless steel fasteners – Part 2: Nuts with specified grades and property classes

Property classes

Property classes of bolts and screws are identified with two numbers separated by a dot. The number to the left of the dot is the tensile strength in MPa divided by 100. The number to the right of the dot indicates the tenfold of the yield point or offset yield ratio.

For example, a screw of property class 9.8 would have the following nominal values:

- Nominal tensile strength: Rm = 9 × 100 MPa = 900 MPa

- Yield point ratio: Re/Rm = 8 ÷ 10 = 0.8

- Yield point: Re = 0.8 × 900 MPa = 720 MPa

The property class of a nut is identified with a single number, which corresponds to the highest property class of a screw with which the nut can be paired. A nut of property class 9 can be paired, for example, with a screw up to property class 9.8.

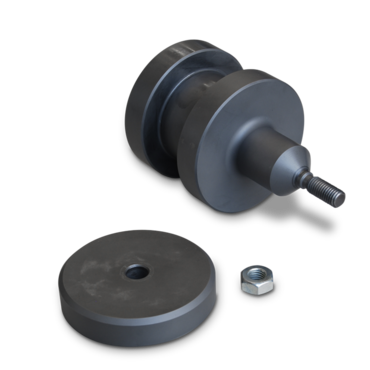

Proof load test on nuts to ISO 898-2

For this test a nut is screwed on to a hardened (45 - 50 HRC) test mandrel and pulled or pressed against an equally hardened (45 HRC) plate. The test load is applied axially to the nut in either a tensile or compression test and held in place for 15 seconds (in case of doubt the axial tensile test is valid (Fig. 5)) When applying the test load, the test speed shall not exceed 3 mm/min.

During the test, the nut may not be unstripped or broken. After removing the load, it must be possible to manually move the nut on the test mandrel. It is permissible to loosen it using a tool, if the turning motion is limited to a half turn.

Hardness testing on nuts

As is the case with screws and bolts, hardness measurement to Vickers, Brinell or Rockwell is permitted. The test to Vickers must be performed with a minimum force of 98 N (HV 10), and for Brinell testing must be performed with a degree of loading of 30, where D again indicates the ball diameter of the indenter in mm.

Routinely the hardness test is carried out on the bearing surface of the nut. The mean value is then calculated from 3 measurements spaced 120° apart.

Determination of core hardness is also defined. In this case a longitudinal section through the nut axis must be prepared. The hardness is measured at about half the height of the nut, and as close as possible to the nominal major diameter of the nut thread.

Widening test on nuts

The purpose of the widening test is to detect surface defects or cracks that can result, for example from hardening. The test arrangement is described in the ISO 10484 standard.

The thread is drilled up to the nominal diameter, and then a conical mandrel (with a very small opening angle (~0,57°)) is pressed into the nut. Before the test, the mandrel shall be lubricated with molybdenum disulfide. Depending on the property class, the nut must withstand widening of 4 - 6 % of the bore diameter. When inserting the mandrel, the test speed shall not exceed 25 mm/min.

The test is considered passing, if the nut can withstand the specified minimum widening without breaking completely.