Testing on intermediate goods and final goods made of plastics

The objectives of testing specimens taken from finished parts or intermediate products differ significantly from those of molding materials testing. Molding materials testing produces material data that can be compared. This data can be used to compare materials, however calculating the characteristics of a finished product is not possible in most cases.

Therefore, tests on intermediate goods and final goods are performed with two different objectives: determination of functional properties and determination of material properties of a good or product.

Component testing: functional product characteristics

A product must have certain functional characteristics. A packing container must be stackable, cable insulation must be able to insulate even under load, a food container must close tightly and still open easily, a window must not break during a storm, and a chair should be able to bear the weight of a heavy person. The list of examples is endless.

In the following application examples we want to show you some of the possibilities when it comes to testing plastic components.

Thanks to our extensive, modular product portfolio and the many ZwickRoell experts in the field of plastics testing, we can easily adapt our testing systems to your specific needs. For an individualized consultation to discuss your particular requirements for components testing, please contact our experts at your convenience.

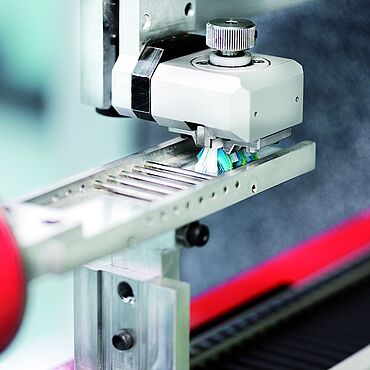

Measuring the notch resistance of low voltage cables

- Every car contains many meters of low voltage cable. These cables run through the entire car and when installed, may make contact with very sharp edges. It is important that the insulation of these cables is not damaged.

- To measure this behavior, the automobile industry developed the LV 112 test method to determine the notch resistance of cable insulation.

- The principle is simple. A cable is placed on a plate and electrically connected to a contact element. The test die has a extremely hard, high-strength wire, also electrically contacted, as the cutting tup. Using the wire, a load is applied to the cable until the electrical contact between the cutting tup and the cable's conductor is established. The force required for this is recorded by the testing machine. This offers a realistic assessment of the notch sensitivity of the cable insulation.

Determining the stack height of packaging

- Yogurt cups, beer crate, or water bottles— each type of packaging is stored for some amount of time in a warehouse and is stacked there. But how may layers of packaging can be stacked without breaking those on the bottom?

- The question can be answered very simply by a testing machine. To find out, the filled or empty packaging is compressed individually or in a stack between the compression platen of the testing machine, measuring the maximum load capacity. The value allows us to determine how many layers can be stacked on top of each other.

- But how can the packaging be improved? Typically, the mechanical characteristics should be achieved using the lowest material cost possible. To achieve this, an intelligent, constructive design is needed and the engineer must understand where the critical points of the container are. The testing machine is equipped with a video camera and the testXpert III Video Capturing Plus option, which synchronizes the film sequence with the force travel diagram. It allows the engineer to analyze the deformation behavior of the packaging under any load and can optimize points that are truly critical.

Activation force of a spray pump

- Many products are marketed in packages that must also perform a specific function.

- One example is a spray pump, which is used for expensive perfume as well as household cleaners. The window cleaner must be stored in the bottle, but must also be able to be sprayed onto the window in a forceful stream or as an atomized spray.

- The activation force must be tolerable for the user, and the dose must be high enough so that the user does not have to pump the handle too often.

- ZwickRoell’s electromechanical testing machines assist here as well, to optimize the product and assist in quality control by measuring the activation force of various pump speeds. Subjective perceptions of quality are measured in this way.

Measuring the required opening force

Measuring the strength of the corners of window frames

Function tests on syringes

Tear-off strength on a backpack

- School backpacks must withstand a significant amount of wear and tear— heavy books, a snack, and whatever else children need at school. They are carried and sometimes hung by their handles and straps. So that backpacks last multiple years, the handles and straps must be firmly attached.

- This example shows a backpack being tested. A clamp from ZwickRoell's product line of tools holds the backpack in the testing machine while a hook pulls on the handle. This ensures that the seams and plastic parts withstand wear and tear for many years.

Component testing - material properties

When testing the material properties of a product, a specimen is removed from a finished product or semi-finished product using a specified removal method and tested according to the same plastics standards that apply to tests on molding materials.

- During the manufacturing process of a finished product or a semi-finished product, the processed polymer is subject to a variety of mechanical, thermal, and chemical loadings and normally forms orientations for the polymer chains and fillers. Therefore, the mechanical properties of a polymer differ at various points of the component.

- To compare material properties of an end product produced by injection molding, extruding, or compression molding, a sampling plan for the specimen is defined. This sampling plan is based on the forming process of the end product and defines the number, form, size, and direction of sampling of the specimen.

- After appropriate conditioning, the specimens taken are tested to the test standards also used in molding materials or to specific information found in the product specification.

- Regular specimen sampling from ongoing production ensures that specific material properties remain constant in one product within predefined tolerances and over longer production periods.

ZwickRoell supplies reliable universal testing machines and extensometers for tensile, flexure and compression tests, as well as pendulum impact testers, hardness testing machines, extrusion plastometers and HDT/Vicat testers in manual and fully automated versions. Thus, the statistical scatter of your results is significantly reduced.

Learn more:

Test standards for tests on molding materials Overview of plastics standards

DIN 53435: characterization of material properties in components made of plastics

The Dynstat bending test, the Dynstat impact test, and the notched impact test to DIN 53435 are used in the characterization of material properties for components made of plastics.

If, for lack of space, only relatively small specimens can be taken from injection-molded parts, the two Dynstat test methods offer interesting options for the comparative characterization of static and dynamic material properties in quality assurance and product development.