ASTM D3574 flexible foam testing

ASTM D3574 is an important standard for the evaluation of flexible cellular materials, which includes tests on physical and mechanical properties such as density, tensile strength and compression and fatigue behavior. The ASTM D3574 standard is particularly used in manufacturing of furniture, mattresses and automotive components. It helps manufacturers guarantee the quality, comfort and durability of their products, by providing standardized test methods for materials testing.

The following is an overview of the most commonly used ASTM D3574 tests that require the use of a ZwickRoell universal testing machine and specific test fixtures. To obtain more comprehensive information, we recommend purchasing the standard from Beuth Verlag or through ASTM.

Overview of all tesets Test A density Test B indentation force Test C compression force Test E tensile strength Test F tear resistance Test H resilience (ball rebound) Test I1-5 fatigue tests Test J - L aging

Automated flexible foam testing Testing machines Request a consultation

Overview of all ASTM D3574 tests

The ASTM D3574 standard includes 19 different tests for the characterization of foams according to the following properties. The marked tests* require the use of a ZwickRoell testing machine and test fixture.

- Test A: Apparent Density (see also ISO 845)

- Test B1: Indentation Force Deflection–Specified Deflection (IFD) and B2 Indentation Residual Gauge Length–Specified Force (IRGL): Indentation hardness* (see also ISO 2439)

- Test C: Compression Force Deflection / Compression Stress-Strain Characteristics* (see also ISO 3386)

- Test D: Constant Deflection Compression Set Test

- Test E: Tensile Strength* (see also ISO 1798)

- Test F: Tear Resistance* (see also ISO 8067)

- Test G: Air Flow Test

- Test H: Resilience (Ball Rebound) Test* (see also ISO 8307, DIN 13014)

- Test I1 to I4: Pre- and post-testing of foams for different types of force application. While I1 is a static test, tests I2 through I4 are run as fatigue tests* (see also ISO 3385:high-cycle fatigue test)

- Test J through L: Aging Test* under different environmental conditions

- Test M: Recovery Time

- Test N: Hysteresis Loss

ASTM D3574 test A and ISO 845

Both ISO 845 and ASTM D3574 test A describe the determination of the apparent density of a flexible foam specimen by calculating it from the mass and volume of the specimen; it is given kg/m3.

The apparent density can be determined directly by connecting a ZwickRoell precision scale to the testXpert testing software.

ASTM D3574 test B

When determining the indentation hardness according to ASTM D3574, a distinction is made between the two methods B1 and B2:

Objective, applications and results of methods B1 and B2:

- ASTM D3574 test B1 Indentation Force Deflection (IFD) is described as an IFD test in which the force is measured, which is required to create certain indentations in foam with a specified compression of 25% and 65%. The hardness determined is given as a force in Newtons (also known as IFD values) at 25% and 65%.

- ASTM D3574 test B2 Indentation Residual Gauge Length (IRGL test) is referred to as the indentation residual gauge length. For this test, the primary interest is in determining how thick foam upholstery should be to ensure comfortable seating for the average person. ASTM D3574 B2 therefore measures the residual gauge length (thickness) of the foam specimen that is retained after loading with a defined force of 4.5 N, 110 N and 220 N. The results are indicated in mm as IRGL values.

Test specimens according to B1 and B2:

- While test B1 specifies a laboratory method for measuring indentation hardness on standard specimens (block foam), ASTM D3574 B2 states that the finished product (molded foam) should be tested if possible, as long as this can be done on a flat surface.

- The standard specimen to ASTM D3574 B1 is removed from a specific section of the finished product and has dimensions of at least 380 mm x 380 mm x 100 mm.

Video: Indentation Hardness to ASTM D3574 Test B

Running a test, test equipment and test results:

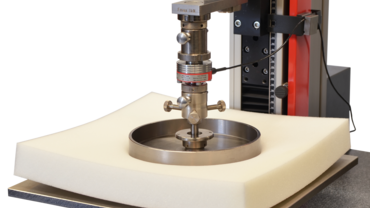

A fixture defined in ASTM D3574 Test B with a flat circular indenter of 203 mm diameter is specified for the test. The ZwickRoell compression fixture for flexible foam can be used for standard compliant testing to both methods B1 and B2. Either the finished product (B1) or the standard specimen (B2) is pressed onto a 400 X 400 mm plate, which is perforated with ventilation holes to allow air to escape quickly during the test.

During the test, the deformation behavior of the flexible foam is measured under precisely defined conditions and displayed in a force-indentation displacement graph. The test consists of preload cycles, which serve to condition the specimen, followed by a measurement cycle in which the characteristic values are determined.

The indentation hardness is also described in ISO 2439 and DIN 53579-1, as well as in a series of specific test methods in the automotive industry. For these tests, ZwickRoell also has the right test fixtures available.

ASTM D3574 test C

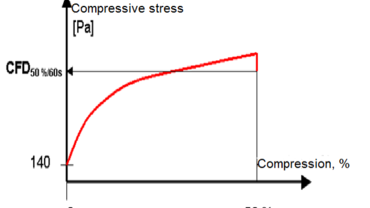

ASTM D3574 test C describes the compression force deflection test on flexible foam for determination of the compression force. This test measures the force required to achieve 50% compression over the entire surface of the defined foam specimens.

Specimen to ASTM D3574 test C:

- The recommended standard specimen according to ASTM D3574 test C has a minimum dimension of 50 x 50 x 25 mm. Larger specimens are preferable. The surface should be at least 2500 mm2 and have a minimum thickness of 20 mm.

Video: Compression Hardness Test to ASTM D3574 Test C

Running a test, test equipment and test results:

- For ASTM D3574 test C, the compressive stress of the entire specimen surface is specified. The compression platens therefore have to be larger than the specimen to be tested. Closed-cell foams require 6.5 mm ventilation holes in the compression platens.

- The test consists of 2 preload cycles from 75% to 80% of the original thickness, followed by a measurement cycle in which the specimen is compressed to 50% of its thickness. The initial height, which is important for the test result, is determined directly before the measurement cycle (in the case of ISO 3386, before the first preload cycle).

- The result is the thickness of the specimen in mm after the measurement cycle and the compression force CFD in kilopascals and is also referred to as load-bearing capacity, compressive stress-strain characteristic, CFD or CLD test.

Compression hardness is also described in the ISO 3386 standard, as well as in a series or specific test methods for the automotive industry, but it differs in terms of technical content. The results cannot be directly compared between the two methods.

ASTM D3574 test C - special testing technology requirements

The measurement of compressive stress-strain curves to ASTM D3574 test C presents a variety of special demands on the testing technology:

- correction of the machine deformation: the load frame and force sensor display an inherent deformation under load. This means that the distance of the compression platen is actually greater than specified. This inherent deformation is recorded by the ZwickRoell testXpert testing software and used for correction. The correction must occur online while the test is in progress, in order to ensure the correct compression platen distance during the hold times.

- Special software functionality includes recording and calculation of the specimen thickness, the pre-calculation of percentage compressions, the handling of two path zero points and two specimen thicknesses (if required), standard compliant calculation of the results and reporting.

ASTM D3574 test E tensile strength

Test E of the ASTM D3574 standard determines the effect of a tensile force on the foam material. In addition to recording a stress-strain diagram, the focus is on determining the maximum tensile strength and strain at break values. The method is used to compare materials, as well as for quality control purposes.

ISO 1798 also deals with the tensile test on flexible foam, but differs in technical content and the results cannot be directly compared between the two methods.

Specimen to ASTM D3574 test E:

The specimens are normally taken from finished parts or a sheet. They must be punched out with a die precisely as defined in the standard in dumbbell form (shoulder specimen). The die must be sharp and free of notches to prevent the specimen from having frayed edges. The preferred specimen corresponds to the shoulder specimen type A according to ASTM D412 with a length of 140 mm and a thickness of 3 to 14 mm. ZwickRoell offers sheet cutting presses with standardized blades.

Running a test and testing machine requirements:

- The tensile tester must be equipped with a load cell to measure the maximum applied force. (zwickiLine image)

- Either laterally acting screw grips with flat jaw inserts or pneumatic grips can be used to grip the shoulder specimens. These exert a uniform pressure on the clamping surfaces, which increases as the tension increases to prevent the specimen from slipping. (Specimen grip image)

- The elongation can be measured with sensor arm extensometers or non-contact extensometers, or via the crosshead travel. Clip-on extensometers, which are clipped onto the specimen are generally not suitable for flexible foam. To measure strain at break, ZwickRoell offers mechanical and optical longstroke extensometers, which record the extension of the specimen within a specified gauge length range.

ASTM D3574 test F tear resistance

Test F to ASTM D3574 describes the determination of the tear resistance of a pre-damaged foam material.

Specimens that correspond to ASTM D3574 test F are type A block specimens with dimensions of 152.4 millimeters (6”) x 25.4 millimeters (1”) x 25.4 millimeters (1”) in which a 40 millimeter (1.5”) cut is made along the specimen (trouser specimen).

The ISO 8067 standard deals with the same subject, but they differ in the type of specimen, whereby the results cannot be compared directly. While ASTM D3574 test F only permits the use of type A trouser specimens/block specimens, ISO allows the use of standardized angle specimens. In interlaboratory tests, method A (trouser specimen) had a scatter of up to 36% and method B according to ISO 8067 (angle specimen) up to 12%.

The tear resistance test can be performed using a zwickiLine electromechanical testing machine. Since the forces are relatively low, a load cell that achieves Class 1 measurement accuracy should be used in the force range used. Displacement measurement is not necessary, as the tear resistance is calculated from the maximum force measured during the test and the average thickness of the specimen: tear resistance: N/m = F/T x 10³

Our testXpert testing software assumes the test sequence and evaluates the tear resistance in accordance with the standard.

ASTM D3574 test H and ISO 8307 rebound resilience

In the ASTM D3574 test H, rebound resilience is measured by dropping a steel ball onto a foam specimen and measuring the height of the rebound. The ASTM D3574 test H is identical to ISO 8307.

The ZwickRoell ball rebound testers meets the requirements of the standard and consists of a vertical, transparent plastic tube into which a steel ball with a diameter of 16 mm / 16.3 g can be dropped from a height of 500 mm. The rebound height is measured using a light curtain. The results are evaluated automatically.

ASTM D3574 tests J, K, L aging tests

ASTM D3574 tests J, K and L describe different types of an accelerated aging test, which investigate the effects of oxidation and/or hydrolysis on the mechanical properties of the foam.

- Aging test J: effect of steam autoclave aging (see also ISO 2440)

- Aging test K: effect of dry heat aging in an air-circulating oven (see also ISO 2439)

- Aging test L: effect of wet heat aging in an environmental chamber (no ISO equivalent)

The principle of this method can be applied to many properties. First, the tests are carried out and measured in the untreated state as described above. This is then repeated in the aged state, e.g. after heat aging (e.g., 7 days at 140 °C) or after hydrolysis aging (e.g., 5 hours at 120 °C).

Heat can be used selectively for aging. The Arrhenius equation describes the acceleration of chemical reactions over time. According to the van’t Hoff rule, the speed of chemical reactions doubles for every 10 °C increase in temperature.

ASTM D3574 test I fatigue test

ASTM D3574 test I1 through I5 describes five methods of constant load fatigue tests on foams:

- Test I1: static test at constant deflection

- Test I2: dynamic fatigue test by roller shear at constant force

- Test I3:dynamic fatigue test by constant force pounding (equivalent to ISO 3385 )

- Test I4: dynamic fatigue test for carpet cushion

- Test I5: dynamic fatigue test by constant deflection pounding

Objective and purpose of the fatigue test to ASTM D3574 test I3

The objective of the fatigue test (constant load pounding test) to ASTM D3574 I3 is determination of the long-term behavior/aging of a foam material through constant mechanical loading. For example, it represents the load applied to a vehicle seat when a car is being driven.

Running a fatigue test according to ASTM D3574 I3:

the complete test is divided into three phases:

- Phase 1: initial measurement: determination of the indentation hardness according to ASTM D3574 test B1 IFD value at 40% compression (or ISO 2439, method A) and determination of the initial hight (d1) after preloading with 4.5 N +/- 0.5N.

- Phase 2: fatigue test by application of a defined compressive load of 750 N +/- 20 N at a frequency of 1.17 Hz to a foam specimen measuring 380 x 380 mm with a circular indenter and a perforated lower compression platen that is larger than the specimen.

- The specimen is either subjected to 8,000 cycles (approx. 2 h) according to procedure A, or 80,000 cycles (approx. 19 h) to procedure B using a fatigue testing machine. Procedure C calls for 12,000 cycles at a slower cycling rate (approx. 20 h), and is especially used for viscoelastic foams.

- Phase 3: repeat the measurement from phase 1, whereby the initial height (and thus the compression zero point) is taken from the first measurement.

The result is the determination of the hardness loss (difference IFD value in kPa) and the height loss / specimen thickness ((d1-d2)/d1 x100%)

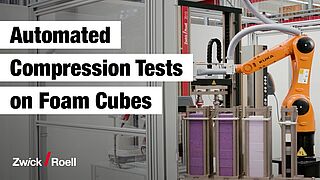

If you have a large testing volume and want to carry out foam testing in accordance with standard specifications in a repeatable, reproducible and therefore, reliable manner,

ZwickRoell can automate almost any test on soft foam—we have years of experience in this field. Our roboTest R testing system would be your top choice for these tests.

Allow us to advise you today in terms of implementation options, costs and return on investment.

Request a consultation Learn more about the roboTest R ROI calculator

Video: Automated testing of cellular foam materials

roboTest R robotic testing system for compression tests with weight and dimension measurement according to ASTM D3574 and many other standards.

Testing machines for flexible foam testing to ASTM D3574

For flexible foam tests to ASTM D3574, ZwickRoell offers a comprehensive product portfolio:

- The universal testing machine of the zwickiLine series is suitable for the test methods with standard specimens according to ASTM D3574 test B indentation force, test C compression force, test E tensile strength and test F tear resistance and is available in four different force ranges (0.5/1/2.5/5 kN) and three load frame heights.

- The ProLine series universal testing machine also enables component testing and the installation of compression platens with a width of up to 400 mm and enables tests with higher forces.

- Our CLine testing machine is specialized for tests on large and small molded foams. With an Fmax of 5 kN or 10 kN and hinged table flaps, it also enables seat testing (1000 x 1450 mm), as well as mattress testing (1000 x 2000 mm) with the use of a sliding table. This makes it particularly suitable for regular production control.

- The electromechanical testing machine (electromechanical servo testing actuator), which allows a high loading speed, can be used for the determination of indentation hardness and compression hardness, as well as for fatigue tests thanks to its simple conversion possibility. With the use of optional retrofit equipment, it can also be used for aging tests in special climate zones with the use of a corresponding environmental chamber.