ISO 3386 Compression Stress Value

The ISO 3386 standard establishes a method for determination of the compression stress-strain characteristic (compression stress value) of low-density flexible cellular materials. ISO 3386-1 deals with soft foams with a density of up to 250 kg/m3, ISO 3386-2 mainly deals with dense elastic foams (foam rubber) with a density above 250 kg/m3.

The compression stress value is the compression resistance that a soft foam specimen, standardized in terms of its dimensions, presents against a defined full-surface compression of 65%, 40% and 25% of the initial height under defined ambient conditions. The compression stress value is expressed in kilopascals (kPa = 10³N/m²). The higher the compression stress value, the firmer it is.

Standards overview Specimens Running a test / Video Results Test equipment Automated soft foam testing Downloads FAQs Request a consultation

Soft foam compression stress value standards

International standards for determination of the compression stress value are standards ISO 3386-1 and ISO 3386-2 and ASTM D3574 test C.

In the automotive industry, there are other test methods that are defined in separate factory standards:

- BMW QV 52009-1

- Daimler DBL 5452

- General Motors GMW 15471, General Motors GME-GMI 60283-8

- PSA D 41003, PSA D 411541

- Renault N° 1002, Renault N° 1541

- Toyota TSM 7100 G Section 4.2

- Volkswagen PV 3410

In some cases, the methods differ in terms of the test procedure and the specific test results, so that results cannot be directly compared between the methods.

Specimens to ISO 3386

- The specimen standardized in accordance with ISO 3386-1 must be a cuboid with a square cross-section of a rectangular cylinder with a minimum width or diameter/thickness ratio of 2:1. The preferred thickness is 50 +/- 1 mm and must not be less than 10 mm. The surface area of the test specimens must not be smaller than 2,500 mm².

- However, ISO 3386-2 does not permit the use of cylindrical test specimens. For specimens according to ISO 3386-2, the square surface to be loaded must have an edge length of at least 40 mm and a width to thickness ratio of 4:1.

ISO 3386 test, test equipment

The compression stress value describes a material property of a soft foam that is determined in a compression test on a standardized specimen. During the test, the deformation behavior of the soft foam is measured under precisely defined conditions and displayed in a stress-strain diagram.

Running a test:

- For the test according to ISO 3386, the compressive stress of the entire specimen surface is specified. The compression platens therefore have to be larger than the specimen to be tested. Closed-cell foams require 6.5 mm ventilation holes in the compression platens to prevent an air cushion from forming.

- In general, the test consists of three preload cycles, which serve to condition the specimen, followed by a measurement cycle in which the characteristic values are determined. The initial height of the specimen is determined directly by the testing machine at the beginning of the first preload cycle.

- In this scenario, the deformation behavior of the specimen is relatively complex. Lateral movement of the cell structure with corresponding shearing occurs near the side cut surface, while the pure compression deformation is predominate in the center. For this reason it is not possible to effectively compare measured values that are determined from specimens of various dimensions using this test method. In the case of ISO 2439 (indentation hardness), however, the influence of the cut edge does not apply, as the indenter is smaller than the specimen. The indentation hardness therefore represents a dimension-independent and reproducible characteristic value if the specimen is sufficiently large, which is well suited for quality assurance and thus offers an advantage of the measurement of the compression stress value according to ISO 3386.

ISO 3386 - Characteristic values

After the fourth cycle (measurement cycle), the force is read off in Newtons at the specified deformation (Fxx). The result are the

- compression stress-strain characteristics Ccxx for any required percentage deformation in kilopascals: Cxx = 1,000 * Fxx/A

- and the compression stress value at a deformation of 40% CV40 in kilopascals (only for ISO 3386-1): CV40 = 1,000 * F40/A

A:specimen surface in mm2

The methods used by Renault and PSA are exceptions. The test consists of a total of five test cycles, of which the first and the last are evaluated. To increase the accuracy of the travel measurement, this standard specifies the correction for machine deformation. These correction options are available with all ZwickRoell testing machines as a standard function.

By integrating a precision scale from ZwickRoell into the testXpert testing software, the bulk density measurement process (ISO 845 and ASTM D3574 test A) can be integrated into the test sequence.

ISO 3386 - special testing technology requirements

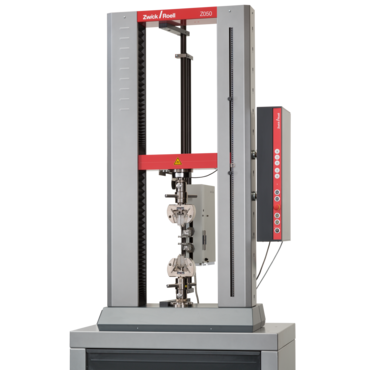

ZwickRoell offers a comprehensive product portfolio for the determination of the compression stress value to ISO 3386-1 and ISO 3386-2:

- The zwickiLine series universal testing machine is ideal for test methods with standard specimens and is available in four different force range (0.5 / 1 / 2.5 / 5 kN) and three load frame heights.

- The ProLine series universal testing machine also enables component testing and the installation of compression platens with a width of up to 400 mm and enables tests with higher forces.

The measurement of compression stress-strain characteristics to ISO 3386 presents a variety of special requirements on the testing technology:

- correction of the machine deformation: the load frame and force sensor display an inherent deformation under load. This means that the distance of the compression platen is actually greater than specified. This inherent deformation is recorded by the ZwickRoell testXpert testing software and used for correction. The correction must occur online while the test is in progress, in order to ensure the correct compression platen distance during the hold times.

- Special software functionality including recording and calculation of the specimen thickness, the pre-calculation of percentage compressions, the handling of two path zero points and two specimen thicknesses (if required), standard compliant calculation of the results and reporting ensure standard compliant testing.

Video: Automated testing of cellular foam materials

roboTest R robotic testing system for compression tests with weight and dimension measurement according to ISO 3386 and other standards

If you have a large testing volume and want to carry out foam testing in accordance with standard specifications in a repeatable, reproducible and therefore, reliable manner,

ZwickRoell can automate almost any test on soft foam—we have years of experience in this field. Our roboTest R testing system would be your top choice for these tests.

Allow us to advise you today in terms of implementation options, costs and return on investment.

Request a consultation today Learn more about the roboTest R Why automate?

FAQs for compression stress value to ISO 3386

The compression stress-strain value, also referred to as compression stress value, is the pressure resistance that a defined specimen under specified environmental conditions applies to a defined whole-surface compression.

The main difference between ISO 2439 indentation hardness and ISO 3386 compression stress value is in the reproducibility of the measured values of varying specimen dimensions within the same test method. ISO 2439 represents a dimension-independent and reproducible characteristic value if the specimen is sufficiently large, which is well suited for quality assurance, since the use of indenters that are smaller than the specimen eliminates the influence of the cutting edge. With full-surface compression to ISO 3386, on the other hand, lateral movement of the cell structure with corresponding shearing takes place near the lateral cut surfaces, while pure compression deformations predominate in the center. For this reason it is not possible to effectively compare measured values that are determined from specimens of various dimensions using this test method.

ISO 3386-1 determines the compression stress value of soft foam with a density of up to 250 kg/m3, while ISO 3386-2 mainly refers to dense elastic foams (foam rubber) with a density above 250 kg/m3. In addition to the compression stress-strain value, which is determined in both ISO 3386-1 and ISO 3386-2, ISO 3386-1 also determines the compressive stress value. ISO 3386-2 requires lower test speeds than ISO 3386-1.