ISO 3385 Fatigue by Constant-Load Pounding

The ISO 3385 standard specifies a method for determining the loss in thickness and loss in hardness of soft foam, in which the longterm behavior of a foam under constant mechanical load is tested using a constant-load pounding test. For example, it represents the load applied to a vehicle seat when a car is being driven. The test method thereby offers the possibility of assessing the performance of upholstery materials made of latex or polyurethane.

The ISO 3385 equivalent is described in the ASTM D3574 test I3, fatigue test by constant force pounding, as well as in other automotive manufacturers’ factory standards.

Standards overview Specimen Running a test Test equipment Request a consultation

Standards for constant-load pounding test on soft foam

International standards for the constant-load pounding test are ISO 3385 and ASTM D3574 Test I3.

In the automotive industry, there are other test methods that are defined in separate factory standards:

- BMW QV 52009 Part 2

- Daimler DBL 5452

- General Motors GMW 15471, General Motors GME 60283 Part 8

- PSA D 42 1047

- Renault n° 1047

- Toyota TS M7100G – 4.8

In some cases, the methods differ in terms of the test procedure and the specific test results, so that results cannot be directly compared between the methods.

ISO 3385 specimen

- The specimen (test piece) in accordance with ISO 3385 is a right parallelepiped measuring 380 x 380 mm and with a thickness of 50 mm +/- 2 mm Upon agreement, the tests may also be carried out on molded parts that do not comply with these dimensions.

- The material may only be tested 72 hours after manufacture and must be conditioned for at least 16 hours at 23 °C / 50% oder 27 °C / 65% relative humidity.

Running a constant-load pounding test to ISO 3385

The complete ISO 3385 test is divided into three phases:

Phase 1: specimen thickness and indentation hardness - first measurement:

First, the thickness of the specimen is measured under a preload of 5 N, as well as its indentation hardness index at 40% indentation and 30s holding time in accordance with ISO 2439 method A.

Phase 2: fatigue by constant-load pounding:

- In the second step, the fatigue by constant-load pounding test, the specimen is subjected to 80,000 cycles by pressing in an indenter with a frequency of 70 +/- 5 shocks per minute. The specimen must be larger than the indenter and smaller than the support plate (perforated).

- The maximum permissible force of 770 N may not be exceeded at any point during the test.

- This load can be applied under normal climate conditions or under defined humidity and temperature conditions.

Phase 3: specimen thickness and indentation hardness - second measurement:

- After the continuous load and after a waiting time of 10 +/- 5 minutes, the specimen thickness and indentation hardness are measured again according to ISO 2439 method A, whereby the initial height and thus the starting point of the test is taken from the first measurement.

The results are loss in hardness and loss in thickness in terms of percentages.

Test equipment for constant-load pounding test according to ISO 3385

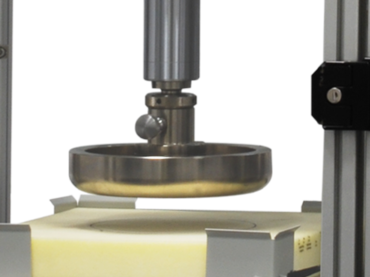

For constant-load pounding tests to ISO 3385, ZwickRoell offers an electromechanical testing machine that permits high loading rates.

The pounding test machine (based on an electromechanical servo-testing actuator) can be easily retrofitted and used for determination of the indentation hardness (to ISO 2439 or ASTM D3574 test B) and compression stress value (ISO 3386 or ASTM D3574 test C), as well as for constant-load pounding tests.

With the use of optional retrofit equipment, it can also be used for aging tests in special climate zones with the use of a corresponding environmental chamber.

A variety of indenters and support plates for standard compliant testing to ISO 3385 and ISO 2439 are also part of the ZwickRoell accessories portfolio.

More information on the electromechanical servo-testing actuator Request a consultation