ISO 2439 Indentation Hardness

The ISO 2439 standard describes an international procedure for determination of the indentation hardness of flexible foam, delivering important characteristic values to determine the load-bearing properties of mattresses, seats, upholstery, etc.

The test processes are also described in standards DIN 53579 (indentation hardness finished parts) and ASTM D3574 test B1 and in various automobile manufacturers’ own factory standards. Below you will find an overview of the test procedure, specimens, test results and the corresponding ZwickRoell product portfolio to meet your specific requirements as well as the requirements outlined by the standards. For comprehensive information, however it is essential to acquire the standard.

Objective and applications Standard overview Request a consultation

ISO 2439 procedure and characteristic values ISO 2439 specimen ISO 2439 test and testing equipment Video ISO 2439

DIN 53579 procedure and characteristic values DIN 53579 indenter Molded foam testing machine

Objective and applications ISO 2439 and DIN 53579

Indentation hardness is the measure of the load properties of a flexible foam in materials testing in the form of a standard specimen (ISO 2439) or a complete finished part / molded foam (DIN 53579) such as a mattress or the cushion of a vehicle seat.

For flexible cellular foam materials, indentation hardness is one of the most important characteristic values used to describe the quality of the product such as comfort level, for example.

ISO 2439 procedure and characteristic values

Indentation hardness is the total force, measured in Newtons, required to achieve a specified indentation under predetermined conditions.

ISO 2439 establishes four different procedures to determine indentation hardness:

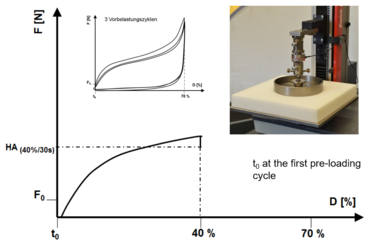

- Method A: laboratory procedure on standard specimens in which a characteristic value is determined for material comparison purposes: indentation hardness index HA(40%/30s) (40% indentation in relation to the specimen thickness at 30s hold time)

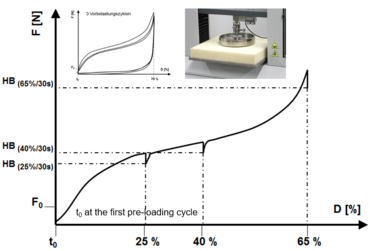

- Method B: indentation hardness characteristic HB(25%, 40%, 65%/30s): here the force (indentation hardness) is measured several times; after indentation of 25%, 40% and 65% followed by a respective hold time of 30s.

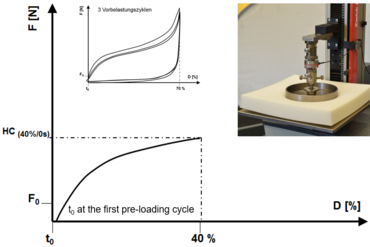

- Method C: quick procedure for quality control to check the indentation hardness HC(40%/0s) without hold time for value correlation to method A. The results obtained can be related to method A, but they are usually higher.

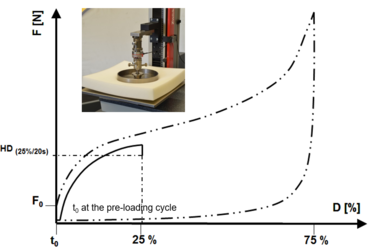

- Method D: low indentation hardness index HD(25%/30s) is an ideal quick procedure for a indentation hardness inspection test with only one preload cycle.

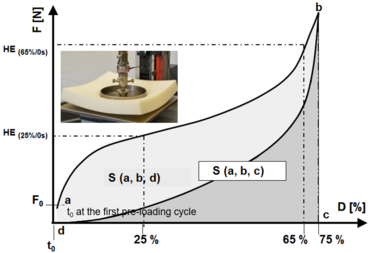

Determination of the compressive deflection coefficient and hysteresis loss rate are established in ISO 2439 method E, which gives additional information about the load-bearing properties of materials.

- Compressive deflection coefficient Sf = ratio of the force at 65% indentation and the force at 25% indentation

- Hysteresis loss rate Af = energy difference between loading and unloading of the specimen during cyclic deformation. It is expressed as a percentage of the load energy.

ISO 2439 specimen

ISO 2439 represents a laboratory procedure for measuring indentation hardness on standard specimens.

- ISO 2439 specimens have a square shape with a side length of 380 mm and a thickness of 50 ± 2 mm.

- However, ISO 2439 can also be used for testing molded foam if this can be done with a flat surface. If this requirement is not met, tests can also be run according to DIN 53579, which is also available in English. Here, the specimens are inserted in as complete finished parts (e.g., seat cushions, headrests, etc.) into specially shaped mold inserts for testing.

- Before the test, the specimens must be conditioned for at least 16h, as described in ISO 23529.

Running a test and test equipment

- In the above described procedures for determining the indentation hardness, compressive deflection coefficient and hysteresis loss rate, different parameters are defined for the test procedure in relation to preload cycles, indentation in the preload and measurement cycles, rest time after preload and compression duration.

- A predefined indenter is used for the test. During the test, the deformation behavior of the flexible foam is measured under precisely defined conditions and displayed in a force-indentation displacement graph. The test consists of preload cycles, which serve to condition the specimen, followed by a measurement cycle in which the characteristic values are determined. There are also other test methods that exist in the automotive industry, some with different test procedures and specific test results.

Standard-compliant testing to ISO 2439 is guaranteed for all methods using a ZwickRoell zwickiLine series universal testing machine and the appropriate compression fixture with support plate and indenter. The ProLine series universal testing machine also enables component testing and the installation of compression platens with a width of up to 400 mm and enables tests with higher forces.

- The support plate must be larger than the specimen and perforated (6 mm holes with 20 mm spacing) to prevent the formation of an air cushion.

- The indentation must be made using an indenter that is smaller than the specimen. The indenter is smooth, circular, 200 to 203 mm in diameter, and has an edge radius of 1 mm.

One advantage of ISO 2439 over the measurement of compression hardness according to ISO 3386 is the elimination of the cutting edge influence. If the specimen is large enough, the indentation hardness value obtained represents a dimension-independent and comparable characteristic value that is well suited for quality assurance purposes.

DIN 53579 indentation test on finished parts

DIN 53579 establishes a procedure for determining the indentation hardness of molded flexible cellular materials with a minimum thickness of 10 mm. This procedure is suited for tests on finished parts such as vehicle seats, headrests, side panels, mattresses, furniture upholstery, and so on.

DIN 53579 procedure and characteristic values

DIN 53579 is used to determine the indentation hardness or remaining thickness of the molded foam under load through:

- the indentation force IF in Newtons, for a defined indentation displacement

- the indentation displacement ID in millimeters, for a defined indentation force.

Testing of flexible cellular foams is described in varying forms in many automotive standards. Daimler and BMW use DIN; the VW sequence is based on DIN but contains additional method descriptions.

Unlike ISO 2439, DIN 53579 only specifies the test methodology, but no test parameters. These are to be agreed with the manufacturers. The indentation method is similar to the principle specified in ISO 2439; relationships to characteristics from tests in other standards (e.g., ISO 2439, ISO 3386-1, ISO 3386-2) may not be established. There is no standardization at ISO level, ASTM D3574 test B2 also describes a procedure for finished parts.

The test sequence consists of three preload cycles, which are run with a significantly greater indentation travel distance than the measuring cycle. The path zero point after application of the preload is valid for all 3 cycles. Before the fourth load (measuring cycle), the agreed preload must be applied again and

the measuring device for the indentation distance must be set to zero.

Specimens in accordance with DIN 53579 are the molded parts in their current form. There is a specific substructure (mold insert) for each version design, which holds the specimen.

The different designs of the molded parts to be tested and the variety of requirements in practice often make it necessary to adapt indenters to the respective testing situation. DIN 53579 provides a choice of three different shapes in various sizes, which have proven themselves in practice.

- Circular, flat indenter

- Spherical/hemispherical indenter

- Circular, convexly curved indenter

In addition to the standard indenter, ZwickRoell offers a wide range of specialized indenters. Request a consultation

Testing machine for foam testing to DIN 53579

Our cLine testing machine is specialized for tests on large and small molded foams and is available in two versions with an Fmax of 5 kN or 10 kN:

- C-shaped design for easy access from three sides

- Hinged table flaps (1000 x 1450 mm) for seat tests

- Sliding table for mattress testing (1000 x 2000 mm), with which the mattress can be easily moved to the desired test position

- The side support plates on this machine can be folded down to test smaller molded parts or for tensile testing

Overview of all standards used for the determination of indentation hardness on flexible foam

| Indentation hardness on standard specimen | ||||

|

|

| ||

| Indentation hardness on molded foam | ||||

| ||||

|

|

|

|

|

|

|

|

| |

Take advantage of the leading testing software in materials testing

With our testXpert testing software, you have access to a complete testing library that covers all relevant DIN, ISO standards and ASTM standards for flexible foam testing. Furthermore, ZwickRoell offers many standard testing machines that comply with the factory standards of automobile manufacturers such as Volkswagen Group, Daimler Chrysler, BMW, GM, PSA Group, Ford, and other renowned companies.

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!