ISO 1798 Tensile Strength & Elongation at Break of Soft Foam

The international ISO 1798 standard establishes a method for determining the strength and deformation properties of soft foam using a tensile test, in which the tensile strength and elongation at break of a predefined specimen are tested under specified environmental conditions.

This method in accordance with ISO 1798 is used to compare materials, as well as for quality control purposes.

ASTM D3574 test E also deals with the tensile test on soft foam, but differs in technical content and the results cannot be directly compared between the two methods.

Specimens Running a test and test equipment Standards overview Request a consultation Downloads

ISO 1798 specimen and dimensions

L0 Gauge length

L Grip-to-grip separation

l1Length of the narrow parallel section/inner diameter

l2 Distance between the wide, parallel sections

l3 Total length / outer diameter

b2 Specimen width in shoulder area

b1 Specimen width in gauge length area

h Specimen thickness

ISO 1798 defines two specimen shapes, type 1 and 1A, in the shape of a dumbbell specimen. The thickness (h) should be 10 to 15 mm in each case.

- The specimen type 1 in accordance with ISO 1798 measures 152 mm x 25 mm x 10 mm to 15 mm (length l3 x width b2 x thickness h). The gauge length L0 must be at least 25 mm and 50 mm max.

- The specimen type 1A in accordance with ISO 1798 measures 120 mm x 25 mm x 10 mm to 15 mm with a gauge length L0 of max 40 mm.

The specimens are usually machined from the finished part or from a panel and must be cut out using a specimen cutting device precisely defined in the standard. This device must be sharp and free of notches to prevent the specimen from having frayed edges. ZwickRoell offers cutting presses with standardized blades. It is important that the blades are equipped with an ejector to avoid the risk of operator injury during specimen removal.

Preparation and conditioning of the foam material or foam specimen to be tested must comply with the ISO 23529 standard.

Running a test and test equipment according to ISO 1798

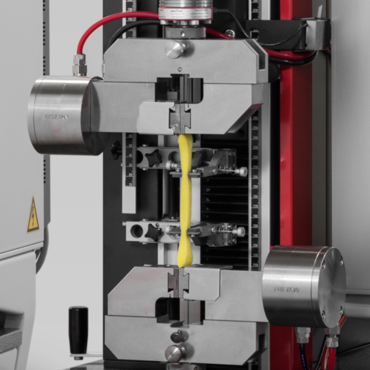

- The zwickiLine series tensile testers are ideal for determination of the tensile strength and elongation at break.

- The cross-section of the specimen must be determined before the test. The width of the specimen is normally taken from the cutting dimension of the cutting blade used, while the thickness is measured under a defined surface pressure in accordance with ISO 1923. For this purpose, ZwickRoell offers special measuring instruments.

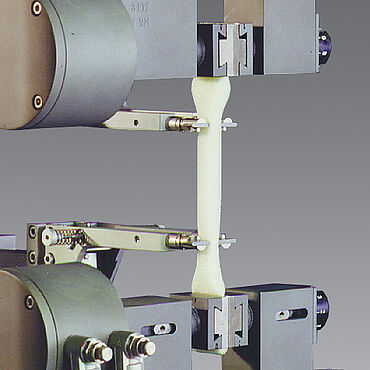

- A variety of pneumatic and mechanical tension specimen grips are available for specimen gripping. The specimen must be gripped in such a way that it is held securely in the shoulder area, but the specimen cannot slip out nor should specimen breakage occur near the gripping area. Either laterally acting screw grips with flat jaw inserts or pneumatic grips that exert uniform pressure on the shoulder area of the specimen—a pressure that increases with increasing tension to prevent the specimen from slipping—are particularly suitable. ZwickRoell's testing lab is available to help you select the right specimen and jaw inserts.

- To measure strain at break, ZwickRoell offers mechanical and optical extensometers, which record the extension of the specimen in a specified gauge length range. These extensometers in large part operate automatically and require little operator intervention, which leads to improved repeatability of test results. When using a mechanical long travel extensometer, you must ensure that the weight and frictional forces of the extensometer remain low in comparison to the measured forces. If optical long travel extensometers are used, it is important that the specimen is not damaged during the marking process.

Reliable calculation and reporting of test results according to ISO 1798

Our testXpert testing software supports efficient testing and reliable results through:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!

Standards for tensile tests on soft foam

The international standards for determination of the tensile strength and elongation at break on soft foam are ISO 1798 and ASTM D3574 test E.

In the automotive industry, there are other test methods that are defined in separate factory standards:

- BMW QV 52009 – Part 1

- Daimler DBL 5452

- Ford WSK - M99 P32 A

- General Motors GMW 15471

- PSA D41 1050

- Toyota TSM 7100G

- VW PV 3410