ASTM D790 3-Point Flexure Test on Plastics

The ASTM D790 standard describes a test method used to determine the flexural properties of unreinforced and reinforced plastics, including high modulus composites and electrical insulating materials. Typical test results according to ASTM D790 include the flexural modulus, stresses and strains at the yield point, the flexural strength and the flexural strain at break. The tests are used for rigid and semi-rigid plastics, however only up to a 5% strain limit.

Additional standards for flexure tests on plastics and fiber-reinforced composites:

- ASTM D6272 - Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials by Four-Point Bending describes a four-point method in which the maximum bending stress between the upper anvils occurs in a shear stress-free zone.

- The standard ISO 178 - Plastics - Determination of Flexural Properties also describes the three-point bend test, however with different technical content

- ISO 14125 - Fiber-Reinforced Plastic Composites - Determination of Flexural Properties establishes three-point and four-point test methods for composites.

Objective & characteristic values Running a test Specimen shapes & dimensions Force measurement & deflection Test speeds Testing software Automation FAQs Downloads Request a consultation

ASTM D790: objective & characteristic values

The 3-point flexure test to ASTM D790 is a traditional standardized characterization method for rigid and semi-rigid plastics. The flexural properties determined with these tests are of great importance to designers, engineers and material manufacturers to ensure that the plastic material used meets the requirements for its intended application.

Typical test results according to ASTM D790 are:

- Flexural modulus: the flexural modulus is a measure of the stiffness of the material and indicates how well it can resist flexural loads. The ASTM D790 standard provides three calculation methods for the flexural modulus, each of which leads to different results:

- Tangent Modulus (Modulus of Elasticity)

The ratio, within the elastic limit, of stress corresponding to strain - Secant Modulus

Ratio of stress to corresponding strain at any selected point on the stress-strain curve - Chord Modulus

Slope between two specified points on the stress-strain curve

- Tangent Modulus (Modulus of Elasticity)

- Flexural strength:Flexural strength provides information about the maximum load that the material can withstand in flexure before it breaks.

- Flexural stress at a specified flexural strain

- Flexural stresses and flexural strains at the yield point and at specimen break

Running a test to ASTM D790

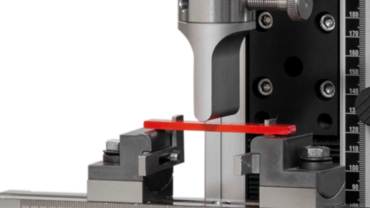

- In the three-point flexure test to ASTM D790, a cuboid specimen is placed on two supports and continuously deformed by a centrally positioned die using a testing machine at a fixed test speed until it breaks, with a strain limit of 5%.

- During the deformation process, the force exerted by the die and the deflection of the specimen under the die are measured.

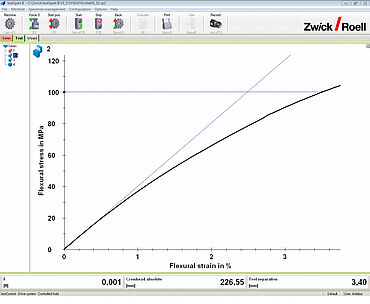

- The resulting load-deflection curve can be converted into a stress-strain diagram using the specimen dimensions and the distance between the supports. It should be noted that the calculation formulas offered by the standard are only valid for small deflections. This is the main reason why the flexure test according to ASTM D790 in Procedure B is limited to a strain limit of 5 %.

ASTM D790 specimen sizes

To test plastics according to ASTM D790, the specimens are produced by injection molding or machined from sheets, plates or molded parts by mechanical processing.

- According to ASTM D790, test specimens with a cross-section of 3.2 mm x 12.7 mm and a length of 127 mm are usually used for plastic molding compounds. The specified thickness to support ratio of 16 leads to a support span of 51 mm. In addition, the standard defines a series of additional requirements for specimens with a thickness greater than 3.2 mm and less than 1.6 mm.

- To test laminated thermosets and sheet materials for electrical insulation, the specimens may have to be machined to a thickness of 25.4 mm or 12.7 mm. If the shear strength is very low compared to the tensile strength, the thickness-to-support ratio must be increased to 32 or even 40 to avoid shear fractures.

- Testing of high-strength fiber composites is carried out according to the tensile shear-strength ratio with a thickness-support distance ratio of 16, 32 or 40. For highly anisotropic materials, a ratio of 60 may even be required for correct modulus determination.

Extreme care is needed when measuring specimen dimensions for a flexure test. Since specimen thickness is calculated quadratically in the flexural stress, the measurement error result is also a quadratic function. A measurement error of only 0.1 mm with a specimen height of 3.2 mm (nominal) produces an error in flexural stress of more than 5 %. For this reason, the thickness of the test specimens is measured using a micrometer that meets the requirements of ASTM D5947.

ASTM D790: measurement of force and deflection

The force measurement according to ASTM D790 must be carried out in the relevant range with an accuracy of ±1 % of the display value. The load measuring system is calibrated according to ASTM E4.

According to ASTM D790, the deflection in the center between the supports can be measured either via the position of the crossbeam (type I) or directly with a separate displacement transducer system (type II):

- For measurement of the crosshead position, an accuracy corresponding to class B according to ASTM E2309 must be maintained. In the case of direct deflection measurement, the test is carried out in accordance with ASTM E83, whereby class B-2 must be observed for the determination of the modulus and class C for the determination of the other strains.

- To measure deflection via the crosshead position according to type I, the testXpert testing software provides automatic correction of the inherent deformation of the test equipment, in which the actual deformation curve of the test arrangement is determined and stored in the testing software.

ZwickRoell offers various type II displacement transducer systems that fulfill these requirements, but differ in particular in their ability to be combined with other test methods:

- Mechanical transducers for compression and flexure tests, designed with a sensor arm that is placed directly under the specimen

- Sensor arms for use with the makroXtens and multiXtens mechanical extensometers

- Measuring devices with markings for the use of optical videoXtens extensometers

ASTM D790 test speeds

Test methods according to ASTM D790 and their influence on the test speed:

- For materials that break at small deflections, the preference is to use a strain rate of 0.01 min-1 according to method A.

- Materials that neither break nor show a yield point up to an elongation of 5 % are tested according to method B with a ten times higher strain rate of 0.1 min-1.

For the operator, this information means that the test speed to be set on the testing machine must be calculated on the basis of the specimen thickness and the support span, or the ratio of support span to specimen thickness. This function can be conveniently stored in the testXpert testing software and the calculation process can be automated.

For the standard specimen with 3.2 x 12.7 x 127 mm and a support ratio of 16, the test speed according to ASTM D790 is:

- To method A: 1.4 mm/min

- To method B: 13.7 mm/min

3 point flexure test kit for ASTM D790

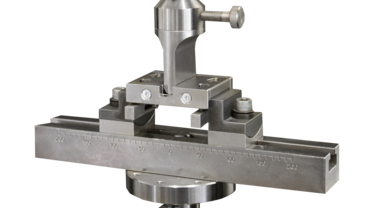

Along with its dimensional accuracy, a key feature of our sophisticated flexure test kit is accurate alignment. The supports must be precisely aligned with one another and with the die. In the stress-strain curve, angular errors can create a curve foot, which can significantly falsify determination of the modulus. Adjustable supports and well-designed gauges make this task significantly easier. Centering stops on the supports make it easy to position the specimen with precision.

Advantages and features of the ZwickRoell 3-point flexure test kit

- With the flexure test kit from ZwickRoell, tests can be performed up to maximum forces of 20 kN. The maximum deflection is 36 mm.

- When using the distance gauge to set the support span and the centering stops, the flexure test kit can be set in accordance with the standards when testing to ISO 178 and ASTM D790.

- Both the span and angle of the supports can be adjusted. This allows them to be centered in relation to each other and to the die, and to be aligned precisely in the support axis.

- The centering stops of the flexure test kit are set and positioned using the distance gauge.

Testing machines for the ASTM D790 three-point flexure test

To perform the 3-point flexure test to ASTM D790, you can use our universal testing machines zwickiLine, ProLine and AllroundLine.

Simply and reliably start testing to ASTM D790 with testXpert

With our testXpert testing software the operator onboarding process is quick and testing can start immediately. They only see tasks that apply to their specific responsibilities and are guided step-by-step through the test according to ASTM D790.

- All characteristic values and settings defined in the ASTM D790 standard are included in the standard test program with guaranteed standard compliance. The testing software guides the user through the test step by step.

- Users only see the steps they have to perform, which are established through the user management feature.

- Specimen dimensions to ASTM D790 are transmitted directly to the testing software through the connection of the micrometer and digital caliper, saving time and eliminating errors.

- testXpert helps you achieve maximum testing efficiency. You can test up to 30% faster.

Maintain a quick, error-free overview

- Through standardized interfaces, test tasks are quickly read in from your ERP or QS system without errors and the results are transmitted back after the test. This saves time in the transmission process and prevents errors.

- Through centralized access to all test data via testXpert Analytics, an evaluation can be carried out on characteristic values from different test series. Also beyond ASTM D790: Tensile modulus, flexural modulus, tensile strength, notched impact strength, flow rates and other characteristic values can be easily reproduced and evaluated.

- With our Trend Analysis feature, you have the ability to recognize longterm deviations with a simple longterm evaluation option.

Automated 3-point flexure test to ASTM D790

When it comes to large volumes of specimens in particular, these tests tie up a lot of personnel. A testing system for automated tests on plastics relieves qualified laboratory personnel of routine tasks and ensures the reproducibility of your test results. This allows employees to take on more complex tasks, such as interpreting test results, evaluating new materials or participating in other research activities.

For the automated performance of 3-point flexure tests to ASTM D790, we recommend the use of our roboTest N, roboTest L or roboTest R testing systems. The combination of different tests, for example tensile tests according to ASTM D638 and flexure tests to ASTM D790, is possible by simple conversion or by including several test fixtures in one system.

Comparison of our automated testing systems for plastics Request a consultation

Frequently asked questions regarding ASTM D790

Both standards provide a method for determining the flexural properties of plastics, but differ in terms of application, specimen geometry and test procedure. For this reason, the test results are not comparable. When testing plastics, differences are to be expected due to the dimensions of the test specimens, which influence the structure of the material. Other influencing variables result from the different test speeds and differences in the determination of the module values.

The ASTM D790 standard describes a test method used to determine the flexural properties of unreinforced and reinforced plastics, including high modulus composites and electrical insulating materials. Typical test results include the flexural modulus, stresses and strains at the yield point, the flexural strength and the flexural strain at break. The tests are used for rigid and semi-rigid plastics, however only up to a 5 % strain limit.

The results of flexure tests according to ISO 178 and ASTM D790 on plastics are typically similar in magnitude, but not directly comparable. The reasons for this are different strain rates in the flexure test, different calculation methods for the modulus value and differences that can arise during specimen production.

ISO standards are developed on the basis of a broad international consensus established by the international standardization committees. These committees consist of representative experts from the national standardization bodies of the participating countries. ASTM standards are developed at the national level in the United States, although ASTM internationally allows experts from outside the US to participate.

The flexural modulus is a measure of the stiffness of the material and indicates how well it can resist flexural loads. Flexural strength provides information about the maximum load that the material can withstand in flexure before it breaks.

Flexural stress is calculated according to ASTM D790 and in ISO 178 as the extreme fiber stress of the specimen in the center between the supports. The formula provided in the standard is based on an ideal load case. Angular errors or frictional forces at the supports, which result from the increasing deflection of the specimen during a flexure test, are not taken into account. The calculation is only sufficiently accurate for small bending angles.

Angular errors between the supports, or between the supports and the die, lead to point contact between the specimen and the test tool at the start of the test. As the load increases, the specimen is deformed in torsion and linear support is achieved. These initial deformations are visible in the stress-strain diagram as a so-called curve foot, that is an increasing gradient in the initial measuring range. The values of the secant modulus and chord modulus can be significantly affected by this, while the tangent modulus according to ASTM D790 is less sensitive to this effect.