ISO 899-1, ISO 899-2, ASTM D2990, ISO 16770: Creep test on plastics

Creep tests on plastics are described in the following standards: ISO 899-1 and ISO 899-2, as well as ASTM D2990. A full notch creep test (FNCT) to ISO 16770 is used to test pipes.

Creep test objective Tensile creep test ISO 899-1 Flexural creep test ISO 899-2 Testing systems

Objective of creep tests on plastics

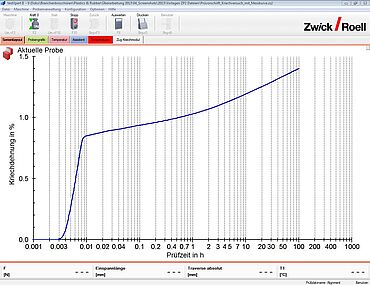

- During a creep test, specimens are subjected to a static load. This corresponds to the load placed on many components made of plastic. The specimen strain is recorded over the course of the test, which often lasts 1,000 hours. Using this data, creep curves can be generated, which depict the long-term behavior of plastics.

- Creep tests on plastics are described in the following standards: ISO 899-1 and ISO 899-2, as well as ASTM D2990. A full notch creep test (FNCT) to ISO 16770 is used to test pipes.

- Since this type of test runs over a long period of time, it is typical to test multiple specimens at once. In this way it is possible to achieve statistically verified test results. The creep testing machines are equipped with multiple test axes.

- Conditioning is an important part of the test. It is necessary to prevent thermal expansion due to temperature fluctuations, which overlap the creep strain. For this reason it is necessary to ensure that the environmental conditions remain constant throughout the test. For test outside of the ambient temperature, accurately controlled temperature chambers are used.

- The specimen strain is determined optically by modern creep test systems that use a high-precision video measurement system. It is mounted behind the test axes to allow access to the system by the operator from the front.

- The electromechanical creep testing machines Kappa Multistation, are equipped with a load cell and one drive per test axis. Along with creep testing, they can be used for quasistatic test methods, for example, to perform a tensile test to ISO 527-2.

ISO 899-1: tensile creep test on plastics

The test axes are equipped with tensile specimen grips. They provide slip-free gripping of the specimen, typically specimen type 1A to ISO 527-2. The test load is calculated according to the requirements and must be applied without jolts and then held constant.

Temperature and humidity are typically recorded throughout out the test.

Specimen strain is recorded by a state-of-the-art measuring system. You can specify the measurement intervals in the testXpert III Software.

The test results are as follows:

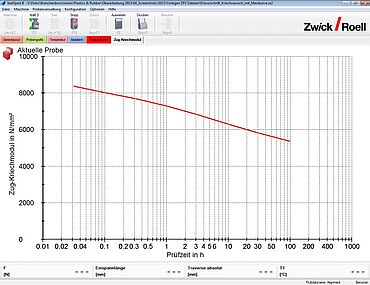

- Tensile creep modulus and the nominal tensile creep modulus

- Creep tensile strength

- Creep curves with logarithmic time axis

- Creep module time curves with logarithmic time axis

- Isochrone stress-strain curves

- Recovery strain curve

ISO 899-2: tensile creep test on plastics

A three-point flexure fixture, as described in ISO 178 for flexure tests, is used as the flexure test tool. The standard ISO specimen has dimensions of 10 x 4 x 80 mm and is taken from the mid-section of the multi-purpose specimen. As is the case with all flexure tests, the specimen height must be measured carefully.

The test load, which is specified prior to the start of the test is based on the polymer characteristics and the intended use, is applied without jolts.

Deflection is measured using either the die movement after correction to the self-deformation of the test arrangement or using a video measuring system.

Temperature and humidity are typically recorded throughout out the test.

The test results are as follows:

- Flexure creep modulus

- Creep flexural strength

- Creep curves with logarithmic time axis

- Creep module time curves with logarithmic time axis

- Isochrone stress-strain curves

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!