ASTM D256 Izod Notched Impact Test on Plastics

The ASTM D256 standard describes impact testing according to the Izod method for determination of the pendulum impact resistance of plastics. Within the scope of ASTM, the pendulum impact resistance of plastics is normally measured using the Izod test to ASTM D256. The flexural impact stress is applied to a notched specimen that is gripped on one end. The result is presented as the thickness-related energy absorption of the specimen.

Izod impact tests are also described in standards ISO 180 and ASTM D4508.

Objective & applications Methods A through E Specimen & dimensions Test performance Video Other related standards Difference Izod & Charpy Impact strength calculation Testing systems FAQs

Objective and applications of the test method to ASTM D256

The Izod notched impact test to ASTM D256 generates characteristic values for the impact resistance and notch sensitivity at high strain rates in the form of a thickness-related energy value. The tests are usually carried out in a normal climate of 23° / 50% relative humidity to ASTM D618.

Applications include:

- The comparison of different molding materials

- Tolerance monitoring within the scope of goods inwards checks and quality assurance

- Testing of finished parts based on machined specimens

- Creation of material cards

- Measurement of aging effects

Izod notched impact tests are also offered as instrumented tests, i.e. with a rapid force measurement. However, there is no standard for this yet.

ASTM D256 - a standard that covers various test methods

The Izod notched impact test to ASTM D256 is used on all plastics to characterize the behavior resulting from impact stresses. The flexural impact stress is applied with edgewise impact to a notched specimen that is gripped on one end. The result is presented as the thickness-related energy absorption of the specimen.

This standard supports various procedures, notch sizes and notch arrangements to test the notch sensitivity of a polymer material

- Method A is used for plastics with an Izod notched impact strength greater than or equal to 27 J/m. In this case, a notch radius of 0.25 mm is used. The result is calculated directly from the height of rise of the pendulum hammer after the impact.

- Method C is used for very brittle plastic materials with an Izod notched impact strength of less than 27 J/m. It corresponds to Method A, however the measured impact energy is corrected by the amount of the calculated centrifugal work of the specimen.

- Method D is used to characterize the notch sensitivity of a polymer material. Here, the notched impact strength is measured on specimens with different notch radii, and the notch sensitivity is calculated as a linear gradient over the notch radius.

- Method E is used to estimate the impact strength on unnotched specimens. For this method, the specimen is gripped rotated by 180° so that the notch is positioned opposite the direction of impact. The result is only conditionally comparable with the test of an unnotched specimen.

ASTM D256 specimens and dimensions

The outer dimensions of specimens to ASTM D256 are specified to a length of 2.5 in (63.5 mm) and a height of 0.5 in (12.5 mm). The width of injection molded specimens may be between 0.118 in (3.0 mm) and 0.5 in (12.5 mm), whereby the use of specimens with a width of 1/8 in (3.2 mm) or 1/4 in (6.35 mm) is common. Exact details can be found in the specifications of the material to be tested, or must be coordinated between the parties involved. For specimens that are machined from components, the wall thickness of the component normally determines the width. Specimens taken from thinner wall thicknesses are tested using the impact test to ASTM D1822.

Since the method describes a notched impact strength measurement, the specimen must be notched.

- For the commonly used Method A, a notch with a radius of 0.25 mm and an angle of 45° is milled into the specimen so that a height of 0.40 in (10.16 mm) remains at the base of the notch.

- If the notch sensitivity is to be measured according to Method D, the specimens must be prepared with different notch radii. In addition to the standard notch according to Method A, specimens are machined with a notch radius of 0.04 in (1.0 mm).

The ZNO motorized notch cutting machine with a standard-compliant single tooth cutter is available for notch preparation. For smaller specimen quantities, we recommend the manual notching plane with automatic infeed movement.

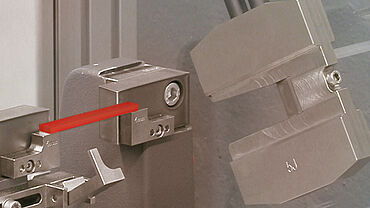

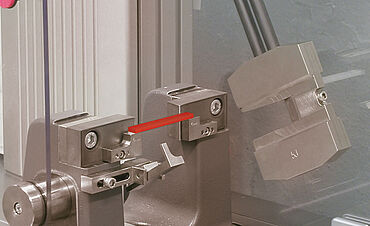

For the test, it is important that the notch is placed exactly in the area of the greatest bending moment. Therefore, the specimens are either positioned using a height stop, or precisely and reliably aligned with a notch alignment unit integrated in the impact fixture.

Performing the Izod notched impact test to ASTM D256

Izod notched impact tests to ASTM D256 use pendulum impact testing machines for plastics with a pendulum hammer that consists of a rod and an impactor on one end, and is attached to a low-friction bearing on the other end.

The measurement principle is based on a pendulum hammer with specified energy capacity and drop height, which releases part of its kinetic energy when it penetrates the specimen. As a result, the pendulum hammer does not return to the original drop height after the impact. The measured height difference between drop height and height of rise therefore becomes a measure of the energy absorbed. By determining the drop height, the impact velocity is also defined so that the tests are performed with reproducible strain rates.

The standard pendulum hammer to ASTM D256 has an initial potential energy of 2.7 J at a specified drop height of 610 ±2 mm. Additional hammer sizes are obtained by doubling the initial potential energy at the same drop height. This results in an impact velocity of approx. 3.46 m/s for all pendulum hammers.

Every pendulum hammer can be used for measurements of impact energies up to 85% of its initial potential energy. If several hammer sizes can be used here, the lightest pendulum hammer should be selected in each case.

The specimen is gripped standing on edge in a specified orientation so that the notch is located exactly at the edge of the gripping point, that is, in the area of the greatest bending moment. Since the gripping force can affect the result, pneumatic gripping or control of the gripping force is useful.

The type of measurement implies that all energy losses are attributable to the specimen. It is therefore important to minimize, correct, or completely eliminate all external sources for error. There are strict specifications, as well as checks that are part of regular calibrations, regarding friction losses that inevitably occur due to air friction and friction at the bearing points of the pendulum hammer. The correction values are measured and assigned to the respective pendulum hammer. Sufficient instrument mass and a vibration-free installation of the pendulum impact tester on a very stable laboratory table, on a worktop bolted into a solid wall, or a masonry platform are essential for the quality of the measurement. Internal vibrations in the instrument are minimized by design. For this reason, ZwickRoell uses pendulum hammers with double rods made of unidirectional carbon materials, which are very low in mass and at the same time offer optimum stiffness of the pendulum rods, ensuring minimal oscillation losses.

Video: Pendulum Impact Testers for Plastics Testing

ZwickRoell’s HIT series pendulum impact testers for the plastics industry offer a high-precision, cost effective solution. The pendulum impact testers are available from 5 to 50 joules and enable not only the standard-compliant performance of ASTM D256 Izod pendulum impact resistance, but also Charpy, Dynstat and tensile impact tests according to ASTM, ISO and DIN.

Other standards for measurement of the Izod impact resistance and notched impact resistance

- ASTM D4812, an Izod test method for the measurement of the impact strength of unnotched specimens

- ASTM D4508, an Izod test method for measurement of small specimens (Chip impact), which is a counterpart to the Dynstat impact test to DIN 53435.

- ISO 180 describes the Izod impact test for determination of the impact and notched impact strength of plastics. It provides characteristic values for the impact strength at high strain rates in the form of a cross-section related value.

Difference between the Izod and Charpy methods

Both methods characterize the impact strength of a material in very similar ways so that the results largely correlate.

- The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards.

- The Charpy impact test, which uses a three-point bending arrangement, is the preferred method in ISO standards.

- Both methods are used to measure notched impact strength, for which the notched specimen is struck so that the notch is in the tensile zone of the bending caused by the impact. For the Izod test, this tensile zone is on the impact side of the pendulum hammer and for the Charpy test is is on the opposite side.

- The Charpy method provides various benefits when testing at low temperatures, since the points of contact of the specimen in the pendulum impact tester are relatively far from the point struck by the pendulum hammer. In this way, the temperature is not affected or withdrawn by the supports in the relevant area and the specimens can simply be fed from a temperature controlled box.

How is the impact resistance calculated?

A conventional Charpy or Izod impact test, measures the impact energy emitted by a pendulum hammer when striking through the specimen. This energy can easily be determined from the difference between the release height of the pendulum hammer and its height of rise after the impact. In the ISO standards, the impact energy is related to the cross-sectional area of the specimen and given in [kJ/m²], while in ASTM standards it is common to relate this energy to the thickness of the specimen to indicate an impact strength value, for example, in [ft lbf/in].

What is notched impact strength?

When testing an unnotched specimen, the result is called impact strength or impact resistance, while tests carried out on notched specimens determine their notched impact strength or resistance.

Optimal integration of the test to ASTM D256 through our testXpert testing software

One testing software solution for everything: impact strength testing to ASTM D256, tensile testing, flexure testing, melt flow testing. And all the data can be evaluated together.

- Numerous import and export possibilities ensure ideal integration of testXpert and ASTM D256 impact testing into your processes. The testing software automatically reads data in and out of other systems, for example, your company’s own ERP or LIMS.

- The measurement of specimen dimensions to ASTM D256 is integrated: During the measurement, the remaining width, height and width of the specimen are transmitted from the measuring device to testXpert at the touch of a button.

- All characteristic values obtained from the impact strength test to ASTM D256, the tensile test, the flexure test and the melt flow test are stored together in one database. The test data is easy to find, evaluate and reproduce—across all applications. Access is easy via web browser from any location that's convenient for you.

- Our Trend Analysis feature provides a simple quality control chart (SPC) that allows you to detect possible deviations from quality specifications in a timely manner.

Frequently asked questions about Izod impact strength to ASTM D256

ASTM D256 is the international standard for determination of the impact strength of plastic and insulation materials.

The ASTM D256 standard describes impact testing using the Izod test method for determination of the impact strength and notched impact strength of plastics. Izod impact tests are also described in standards ISO 180 and ASTM D4508.

The Izod notched impact test to ASTM D256 generates characteristic values for the impact resistance and notch sensitivity at high strain rates in the form of a thickness-related energy value. The tests are usually carried out in a normal climate of 23° / 50% relative humidity to ASTM D618.

It is used to determine the comparability of different molding compounds, tolerance monitoring within the scope of goods inwards checks and quality assurance, testing of finished parts based on machined specimens, creation of material cards and for measurement of aging effects.

- The Izod notched impact test to ASTM D256 generates characteristic values for the impact resistance and notch sensitivity at high strain rates in the form of a thickness-related energy value.

- ASTM D4812, an Izod test method for the measurement of the impact strength of unnotched specimens

- ASTM D4508, an Izod test method for measurement of small specimens (Chip impact), which is a counterpart to the Dynstat impact test to DIN 53435.

- ISO 180 describes the Izod impact test for determination of the impact and notched impact strength of plastics. It provides characteristic values for the impact strength at high strain rates in the form of a cross-section related value.

Both test methods characterize the impact strength of a plastic material. The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards. The Charpy method, which uses a three-point bending arrangement, is the preferred method in ISO standards.

Both methods are used to measure notched impact strength, for which the notched specimen is struck so that the notch is in the tensile zone of the bending caused by the impact. For the Izod test, this tensile zone is on the impact side of the pendulum hammer and for the Charpy test it is on the opposite side.

A Charpy or Izod impact test measures the impact energy emitted by a pendulum hammer when striking through the specimen, which can be determined from the difference between the release height of the pendulum hammer and its height of rise after the impact. In the ISO standards, the impact energy is related to the cross-sectional area of the specimen and given in [kJ/m²], while in ASTM standards this energy is related to the thickness of the specimen to indicate an impact strength value, for example, in [ft lbf/in].