ISO 527-3 Tensile Test on Plastic Film

Tensile tests on plastic films are of great importance in the film packaging industry, but also in battery testing of separator films.

ISO 527-3 specifies the test conditions for determining the tensile properties of plastic films and sheets with a thickness of less than 1 mm and is based on the general principles specified in ISO 527-1, such as conditioning, test procedure, test equipment and results.

The ASTM equivalent to ISO 527-3 is ASTM D882, which, however, cannot be regarded as technically equivalent, as it not only differs in the specimen geometries, but also places lower demands on the accuracy of the strain measurement.

Plastics with a thickness of more than 1 mm are tested according to ISO 527-2 or ASTM D638.

Characteristic values Tensile test on separator films Specimens Running a test & test equipment Automated film testing Downloads Customer projects Request a consultation

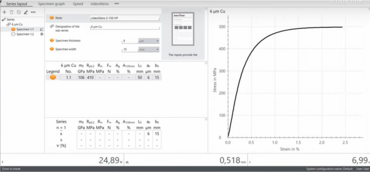

ISO 527-3 characteristic values

The tensile test on plastic film provides measured values about the behavior of a material under quasi-static, uniaxial, continuously increasing tensile load.

Typical test results are characteristics such as

- Yield stress

- Yield strain

- Maximum stress and nominal strain at break

When testing strip specimens, the strain at break results depend on the specimen shape and the type of specimen gripping used. We recommend the use of parallel clamping specimen grips. The grip inserts should be arranged so there is linear contact between the jaw and the specimen.

Tensile test on separator film in battery testing according to ISO 527-3

Separator film in a lithium-ion battery separates the anode and cathode from each other to prevent electrical short circuits. At the same time, the separator allows the flow of ionized charge carriers that are needed to close the circuit in an electrochemical cell.

In addition to ceramic separators and glass fiber nonwovens, polymer membranes are primarily used. Reliable determination of the tensile strength and strain at break provides information about the integrity of the separator film under operational mechanical stress.

While thicker separator film efficiently and safely prevents contact between the anode and cathode, thinner film makes it possible to reduce the weight of the battery and improve the energy density.

In terms of testing, the main requirements for separators are covered by tensile tests according to ISO 527-3 and ASTM D882 as well as puncture tests according to EN 14477, ASTM D5748 and ASTM F1306. These tests are also carried out in an electrolyte-wetted state in order to achieve realistic mechanical characteristics.

Active involvement in the further development of these standards, especially for battery materials, ensures that ZwickRoell test methods will continue to meet all future requirements.

Running at test according to ISO 527-3

The tensile test on plastic films is carried out as described in ISO 527-1 section 9. For films, you need to note the following:

- for specimens cut from sheets or films, it can be assumed that the width of the5 film cutting tool corresponds to the width of the test specimen. Any specimen with visible defects on the cut edges must be discarded. Properties of certain films can change with the in-plane direction (anisotropy), so specimens of both orientations should be tested.

- If optical extensometers are used, especially for thin sheets and films, it is necessary to mark the gauge length with gauge marks on the specimens. It must be ensured that these are not scored, punched or embossed in order to rule out damage to the specimen.

- When clamping the specimen, it is essential to ensure that the specimen is aligned vertically. The specimen grips used must be able to hold the thin plastic film specimen evenly and securely during the tensile test without causing the specimen to slip or crush/break in the specimen grips.

- During the centering of a less rigid film specimen or due to clamping pressure, the specimen can already be pre-tensioned before the test begins. This is necessary to avoid a curve foot in the stress-strain diagram. A standard-compliant preload can be defined using the testXpert testing software, thus ensuring accurate and repeatable test results.

Test equipment for the tensile test on plastic film according to ISO 527-3

Testing machines:

Since plastic film specimens break at relatively low forces, the ISO 527-3 test is often performed on a zwickiLine 500 N single-column universal testing machine. Due to the sometimes high elongation at break of the film specimens, the zwickiLine with additional height or a two-column frame from the ProLine or AllroundLine series (for advanced functions and automated testing) may be required for testing up to break.

Specimen grips:

For secure and gentle clamping of the film specimens, we recommend the use of parallel clamping pneumatic 1 kN specimen grips with aluminum/Vulkollan jaw inserts.

Insertion aid:

The insertion aid for safe and fast insertion of thin plastic films into the specimen grips ensures vertical alignment of the specimen by reducing user error and operator influence when positioning the specimen. This ensures reliable test results and increases specimen throughput. The insertion aid is available for strip specimens of different widths and lengths in accordance with ISO 527-3.

Extensometers:

For strain measurement, ISO 527-1 requires use of a suitable extensometer. When measuring the elongation of plastic films, the specimen must not be loaded with the mass of the extensometer in order to prevent premature breakage of the specimen. We therefore recommend the use of a non-contact video extensometer (videoXtens 2-150 HP (measuring range up to 175 mm) or videoXtens 1-270 P (measurement range up to 330 mm), depending on the expected strain of the specimen).

Film tensile test to ISO 527-3 with our testXpert testing software

Our testXpert testing software makes carrying out the film tensile test in accordance with ISO 527-3 simple and reliable:

- Guaranteed standard-compliant and operator-independent: The test program is parameterized and validated centrally at our company in accordance with standards. All system configuration parameters are loaded automatically. Compliance with the extensive requirements of the standards is not dependent on individual persons.

- Uncompromisingly adapted to the standard: The tool distances are set absolutely and tamper-proof in the test program. This allows the correct grip-to-grip separation for the specimen, e.g. 100±5 mm, to be recognized and tracked at a glance.

- Time saving, as every test counts: The results can also be recalculated after the test if, for example, the specimen geometry is corrected.

ISO 527-3 specimen

According to ISO 527-3, films and sheets with a thickness of up to 1 mm are tested using strips or dumbbell specimens.

- The recommended specimen shape is the strip. This specimen shape can be easily machined using a specimen or film cutter.

- Dumbbell specimens are often used in quality control. For this, a direct measurement extensometer is required to measure the specimen strain directly at the specimen.

- ISO 527-3 requires the application of two parallel gauge marks at a distance of 50 mm (L0) on the center of the test specimen.

| Specimens | Note | l3 mm | l1 mm | b2 mm | b1 mm | h mm | L0 mm | L mm |

|---|---|---|---|---|---|---|---|---|

| Type 2 (strips) | Recommended specimen | ≥150 | 10 to 25 | ≤1 | 50±0.5 | 100±5 | ||

| L can be reduced to 50mm for larger elongations | ≥150 | 10 to 25 | ≤1 | 50±0.5 | 50 | |||

| Type 5 (dumbbell specimen) | QA applications; recommended for very high strain at break | ≥115 | 33±2 | 25±1 | 6±0.4 | ≤1 | 25±0.25 | 80±5 |

| Type 1B (dumbbell specimen) | QA applications; recommended for rigid sheets | ≥150 | 60±0.5 | 20±0.5 | 10±0.2 | ≤1 | 50±0.5 | 115±5 |

| Type 4 (dumbbell specimen) | QA applications; recommended for thin sheets | ≥152 | 50±0.5 | 38 | 25.4±0.1 | ≤1 | 50±0.5 | 98 |

Automated film testing to ISO 527-3 with the roboTest F robotic testing system

Quality assurance is essential in the production of plastic films. In addition, a growth market such as the electric vehicle industry requires automated solutions to increase throughput and efficiency in film testing due to increasing test volumes. ZwickRoell has developed the roboTest F robotic testing system for this purpose.

- The testing system includes an AllroundLine testing machine with an extended test area.

- Specimens for tensile testing are fed into the system by a specimen magazine that holds up to 200 specimens.

- The magazine consists of a base and a revolving chain with grippers for gripping the specimen.

- These grippers vary depending on the specimen type and shape. This means that films of various dimensions can be tested using the same system.

In addition to the medium-term reduction in testing costs, the advantage of this system lies in error-free testing. Test results are highly reproducible due to the elimination of operator influence.

More about the roboTest F ROI calculator Request a consultation

Downloads for tensile test on plastic film to ISO 527-3

- Industry Brochure: Plastics & Rubber PDF 9 MB

- Product Information: zwickiLine Testing Machine up to Fmax 5 kN PDF 820 KB

- Product Information: Pneumatic Grips Fmax 1 kN PDF 3 MB

- Product Information: Insertion Aid for Thin Flexible Foils/Films PDF 714 KB

- Product information: videoXtens 2-150 HP PDF 1 MB

- Product Information: videoXtens 1-270 P PDF 1 MB

- Product Information: roboTest F Automation for Non-Rigid Specimens PDF 98 KB