Spring Testing & Spring Testing Machines

Spring testing machines, also known as spring testing devices or spring test machines are used to test the quality performance of springs and ensure that they meet the specified requirements.

Spring testing machines are available in various designs and sizes to test different types of springs.

Multi-channel spring test Uniaxial spring test Multiaxial spring test Spring test on pneumatic springs Fatigue testing Testing systems Downloads

ZwickRoell offers special spring testing machines for a wide variety of spring systems

Springs are among the most important classical structural elements and are used for energy storage and energy conversion. Here the elastic properties of the materials are used. Without springs—regardless of their design—no mechanical or electro-mechanical system would operate. The main functions of engineering springs are:

- Absorbing impacts and vibrations

- Distributing and counterbalancing forces

- Maintaining pretensioning

- Maintaining a defined position or state

- Measuring and regulating forces and moments

Key features of spring testing machines:

- Provide the highest level of accuracy and repeatability for testing springs with very small tolerances

- Force is applied to the center axis of the test area

- Deformation of the load cell and the load frame is compensated during the test in the testXpert III testing software via a correction curve.

Spring testing machine for multi-channel spring testing

Multi-channel measuring platforms allow the force vector of compression coil springs (used as a valve spring or in MacPherson struts) to be determined.

Standard testing systems are equipped with a six- or nine-component force measuring platform for the spring testing machine. This enables the specific determination of the spring intersection points and the resulting force from the force components when loading the spring under compressive force. These characteristic values are important to evaluate the following quality attributes: friction, wear, and service life.

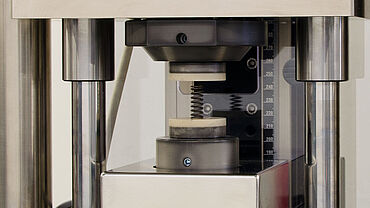

Uniaxial spring testing machine for helical compression springs

Rapid technical advance has led to a significant increase in the demands placed on the accuracy and durability of springs. The corollary of this is greater demands on manufacturing accuracy due to ever-smaller dimensional, form, and positional tolerances, with similarly enhanced requirements for testing technology.

The zwickiLine (single-column testing machine) with testControl II electronics, together with the precision spring compression test kit, is ideally suited for use as a precision spring testing machine. The kit is extremely transverse force-resistant and protects against overload. The grounded, demagnetized compression platens have a parallel alignment accuracy of 1 μm / 10 mm. The precision guides only allow precise vertical movement of the compression platens in order to avoid the influence of shear forces. Accurate load application on the springs leads to highly precise test results. In addition, real-time collision protection functions and mechanical overload protection increase operator safety. Furthermore: reliable test results, even with different operators, thanks to testXpert, our intelligent testing software.

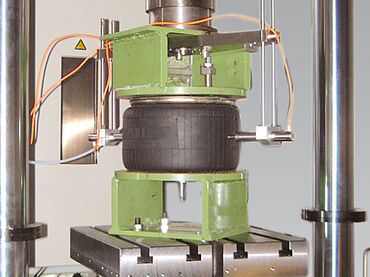

Spring testing machine for multi-axial testing of struts

This spring testing system is equipped with three test axes to measure the damping characteristics of the hydraulic shock absorbers. The vertical force (wheel load) is applied by the testing machine axis. Horizontal forces and torsional moments that occur when maneuvering curves, when starting or braking, etc., are generated by a horizontally mounted electromechanical actuator and a torsion drive. The test axes can be individually and independently controlled from one another. This way you can determine the characteristics (damping friction, viscosity) at different axial speeds with and without lateral forces and torque.

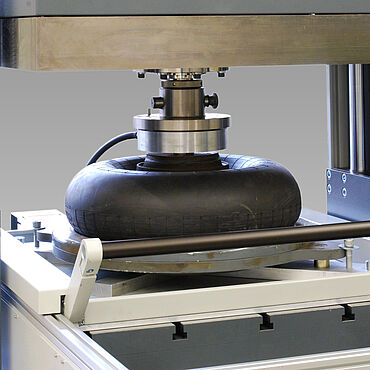

Spring testing machine for testing of pneumatic springs

With a spring testing machine, the viscoelastic properties of pneumatic springs and their fatigue properties are examined under various temperatures.

A servo-hydraulic testing machine with hydrostatic cylinder bearing serves as the foundation. A special compression unit (mounted on a T-slotted plate) allows you to mount various pneumatic spring shapes and sizes. The fixture is also equipped with two measuring transducers for measuring the pneumatic spring diameter. The entire fixture can be inserted into a mobile temperature chamber in a temperature range of -80 °C to +250 °C.

Multi-axial loading of pneumatic springs to EN 13597

This spring testing machine supports quality assurance and the development of pneumatic springs. It consists of a floor-standing testing machine with Fmax 250 kN. It is equipped with an additional horizontal, electromechanical drive with Fmax 50 kN and a force measuring platform with five load cells (3 vertical and 2 horizontal).

The axial and horizontal stiffness characteristics of pneumatic springs are determined under vertical, horizontal or combined loading, and the following channels can be individually controlled:

- Force and travel, vertical

- Force and travel, horizontal

- Air or liquid internal pressure

For easy insertion of the specimen, the spring testing machine is equipped with a loading table that can be used to push the specimens into the spring testing machine.