ARGUS Additive Plastics GmbH: Customized Masterbatches for Many Industrial Applications

Reference

- Customer: ARGUS Additive Plastics GmbH

- Location: Büren, Germany

- Industry: Plastics, chemical

- Topic: Tensile tests on UV resistance

ARGUS Additive Plastics GmbH

High-quality masterbatches for individual customer requirements.

ARGUS Additive Plastics GmbH is a family-owned company founded in 1994 and based in Büren, North Rhine-Westphalia. The company produces innovative masterbatches based on PE, PP and various technical polymers and biopolymers that set the highest quality standards. ARGUS masterbatches are highly filled plastic granules with functional additives or color pigments that give the end products certain properties. These include light stabilizers, flame retardant batches, color masterbatches, UV-IR absorbers, antioxidants, antistatic agents, processing aids, antiblocking agents and many more. ARGUS specializes in customer-specific developments and combination masterbatches, which are adapted according to customer requirements. Customers use ARGUS products in the pipe, profile and sheet industries, for example, as well as for the production of nonwovens, artificial turf and films.

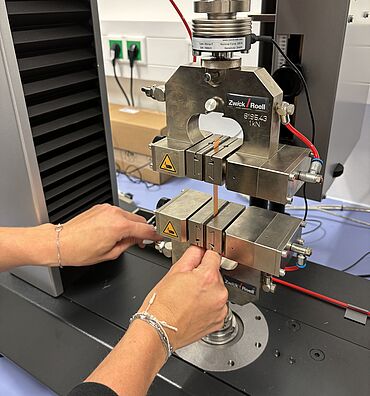

Efficient and precise material tests with the 10 kN ProLine from ZwickRoell

The company chose a testing machine from the ProLine series to carry out standards-based tests. For the most part, tests are performed on films, fibers, filaments and tension rods as well as various fabric samples. The machine was adapted to specific requirements with the appropriate accessories from ZwickRoell.

Experience with the 10kN ProLine:

- Quick and easy operation, also with regard to the testXpert testing software.

- The two different load cells (200 kN and 10 kN) provide an exceptionally wide measuring range, which makes it possible to test other materials.

- The use of an extensometer also makes it possible to carry out more precise measurements and determine other material parameters, such as the modulus of elasticity.