Bruker-Spaleck GmbH Tests the Tensile Strength and Strain at Break of Flat Wire According to ISO 6892-1 – Wire Testing with ZwickRoell

Case Study

- Customer: Bruker-Spaleck GmbH

- Location: Hardt, Germany

- Industry: metals, automotive, electronics/mechatronics

- Topic: metals, wire testing, flat wire in fine and ultra-fine range

February 2024

To determine both the tensile strength and strain at break, Bruker-Spaleck GmbH tests fine and ultra-fine flat wire according to ISO 6892-1. Reliable test results and optimal documentation of the measured values are critical components of the company’s quality management processes. Here, ZwickRoell contributes by providing customized solutions for wire testing.

Bruker-Spaleck GmbH

As part of the Kern-Liebers Group, Bruker-Spaleck GmbH specializes in high-precision production of flat wire products. In line with their expertise in flat wires in the fine and ultra-fine range, the company motto is “kleiner, feiner, spezieller”, which translates into “smaller, finer, more special”. As a renowned manufacturer, the company offers customized wire products for various industries, including the automotive and medical industries. The products, such as flat wires made of steel, copper, aluminum or even flat enameled wire, include different strength ranges, surface coatings (e.g., nickel, silver, tin, etc.) or edge finishes. The company is able to implement the tightest tolerances and customized orders from small batch sizes to large series.

With a clear focus on precision and quality, Bruker-Spaleck GmbH offers innovative flat wire solutions to meet the strict quality standards their customers demand. Through a close connection with the Kern Liebers Group, the company has a deep level of expertise and many years of experience with access to a global network.

ZwickRoell top competences

- Precision and reliability in wire testing

- Perfect documentation of the test results

- Simple machine operation

- Extensive training expertise

- Comprehensive consultation in the design and use of clamping devices for wire testing

- Lasting and trustworthy partnership

The task

Challenges in wire testing, especially on flat wires

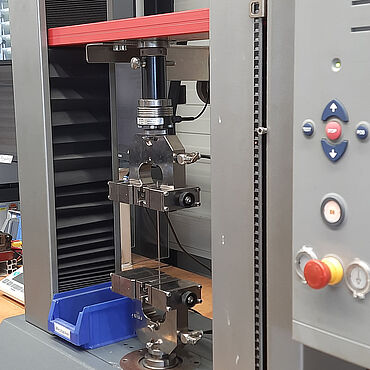

Testing of fine flat wires made of copper alloys in a thickness range of less than 50 µm and in a soft-annealed state poses particular challenges: secure gripping is crucial to ensure reliable results. Accurate determination of the mechanical characteristic values, in particular the uniform elongation and offset yield, presents another demanding task.

Testing of high-strength flat wire made of stainless steel also requires a careful approach. Stable gripping, without slipping in the jaws, is essential for an accurate analysis. Safe determination of the yield point ratio and strain at break plays a key role and requires the use of precise testing solutions.

The ZwickRoell solution

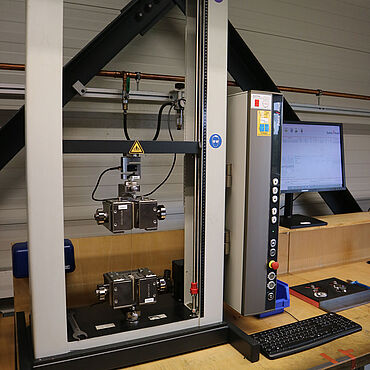

ZwickRoell Z005 and Z010 testing machines for wire testing

Determination of the tensile strength and strain at break represent critical steps in wire testing and quality assurance. This includes recording the measured values in a data acquisition system and determining additional characteristic values. It is important to carefully record and archive all values determined during the tensile test. This is key in attaining transparency and traceability of test results, further supporting the quality assurance process. With precise documentation it is possible to identify discrepancies and implement corrective action in a timely manner.

Bruker-Spaleck GmbH carries out wire testing according to international standards, which define test methods for the determination of the mechanical properties of metallic materials—in particular the tensile test to ISO 6892-1. Strict compliance with this standard and the guarantee of repeatable and reproducible results are therefore fundamental prerequisites for the company’s consistent product quality. By using ZwickRoell’s AllroundLine Z005 and Z010 testing machines, the company has found a comprehensive approach to meeting the given challenges and ensuring the quality and reliability of their products in various industries.

The result

Focus on measured values, characteristic values and state-of-the-art

Documentation of the measured values:

An important consideration when using testing machines for different industries and applications is documentation of the measured values. Through precise acquisition and storage of measurement data, Bruker-Spaleck ensures the quality of their products and guarantees compliance with the necessary standards. By implementing ZwickRoell’s testXpert testing software and using the data management option, accuracy and efficiency of the measured value documentation is significantly improved. Furthermore, complete traceability of the test results is ensured.

Determination of additional characteristic values:

In addition to the standard values acquired by materials testing machines, ZwickRoell machines help you determine further characteristic values for a more comprehensive understanding of the products or materials being tested. You can, for example calculate specific values in order to identify emerging issues at an early stage.

State-of-the-art:

Modern testing machines and testing solutions, as those offered by ZwickRoell, have the capability to test a wide range of materials and products, and present ongoing adaptation possibilities to meet changing requirements. For example, real-time monitoring and analysis of measurement data enable quality assurance and product development to be continuously improved.

Overall, the use of testing machines is of crucial importance in today’s industry in order to guarantee the quality of products and materials. Documentation of the measured values, determination of additional, non-standard characteristic values and the integration of modern technology are key factors in increasing the efficiency and effectiveness of test methods and ensuring a company’s competitive position. It is essential to keep up to date with the latest technology and to integrate these developments into your own processes in order to meet constantly increasing requirements.

“For us, the tensile testing machines from ZwickRoell have opened new doors to fully understanding our flat wire products, which not only benefits our quality testing processes, but also our customer around the world. In addition, we have optimized the efficiency and effectiveness of our test methods and significantly increased our competitive position.”

Christian Seeger, Head of Engineering Bruker-Spaleck GmbH