Testing Machine for Timber Research and Technology: NMBU Uses Z1200ES from ZwickRoell

Case Study

- Customer: Norwegian University of Life Sciences (NMBU)

- Location: Ås, Norway

- Industry: Wood

- Topic: NMBU: Testing of timber and construction elements with the Z1200 for instructional purposes and timber research and technology.

May 2024

Researchers at NMBU are testing how climate and forestry influence different timber properties and how these properties relate to the performance of different timber products. The objective of this research is to increase the production of high-quality timber and to optimize and implement particularly sustainable constructions by reducing the carbon footprint.

Norwegian University of Life Sciences (NMBU)

The Norwegian University of Life Sciences (NMBU): pioneer in the fields of life sciences and sustainability.

The Norwegian University of Life Sciences (NMBU) is a renowned educational institution in Ås, Norway. Founded in 1859, the university has a long history of promoting education, research and innovation in the life sciences. NMBU is internationally recognized for its programs and research areas in agricultural sciences, forestry, veterinary medicine, environmental sciences, landscape architecture and related disciplines. The university offers a wide range of bachelor's, master's and doctoral degree programs that attract students from all over the world.

Research at NMBU focuses on overcoming global challenges in the areas of food security, sustainability, environmental protection and health. Through partnerships with governments, industry and other academic institutions, the university actively contributes to the development of strategies and solutions that have a positive impact on society and the environment. The NMBU fosters an open and inclusive learning environment that promotes creativity, critical thinking and interdisciplinary collaboration. With modern facilities, highly qualified faculty and a vibrant campus community, the Norwegian University of Life Sciences offers an inspiring platform for students and researchers who want to explore the challenges and opportunities in this field.

ZwickRoell top competences

- Outstanding quality and reliability of timber testing machines.

- Expert advice, fast and reliable ZwickRoell service.

- Large number of specimens can be tested with very high accuracy and reproducibility of results.

- testXpert testing software makes it easier to adapt test setups and enables simple and safe machine operation.

- External devices such as high-precision measuring transducers and digital image correlation systems can be connected to measure deformations of different specimens and connections.

- Upper drive and lower base facilitate the handling of large specimens.

The task

Testing timber properties and structural elements

According to UNEP 2022*, around 42 percent of man-made greenhouse gas emissions are attributable to the construction sector. These emissions include both materials and processes related to construction and demolition.

As a natural, renewable raw material, wood can replace building materials with higher carbon emissions and thus make a decisive contribution to reducing greenhouse gas emissions in the construction sector. There is a trend towards the use of timber in a wider range of applications, and for many of these applications mechanical performance is extremely important.

Research at NMBU covers the entire timber value chain, from the forestry and wood sector to the use and recycling of timber products in the construction industry. The objective of the research is to increase the production of high-quality timber and to optimize and realize the benefits of particularly sustainable constructions with a reduced carbon footprint.

As the properties of timber vary greatly, knowledge of these differences is important for the efficient use of this natural resource. The timber research group deals with a number of issues: How do climate and forestry practices influence the properties of timber? And how can these relationships ensure the high quality of timber products?

The timber construction research group has a long tradition of research in the field of construction. The expertise includes characterization of the mechanical performance of joints and components, the design of timber buildings under static and dynamic loads, the evaluation of existing timber buildings and the retrofitting of historic and listed buildings.

*United Nations Environment Programme (2022). 2022 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector. Nairobi.

The ZwickRoell solution

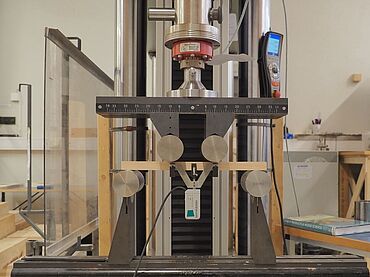

Materials testing machine Z 1200 ES with a test load of 1200 kN.

NMBU relies on the 1200 kN ZwickRoell Z1200 ES materials testing machine, which also has a side test area with a capacity of 250 kN. The machine is part of the NMBU timber laboratory. It is mainly used for timber science studies at the Faculty of Environmental Sciences and Natural Resource Management (MINA) and for timber construction studies at the Faculty of Science and Technology (REALTEK).

The frame is equipped with a top-mounted drive that provides a comfortable working height for placing large samples in the work areas. The electronics are equipped with additional modules to receive signals from several LVDTs, load cells and other sensors (multifunction module).

The two faculties use the machine to carry out standardized tests on small specimens of natural timber, modified timber and various timber composites, timber-based materials and construction timber. Tests are also carried out on glued-laminated timber, cross-laminated timber and construction elements. In addition to their own research and instruction, NMBU also carries out material and prototype tests for research institutes and companies.

The result

Precise testing of timber and components

Both researchers and students benefit from a high-performance machine with very high accuracy that can be easily programmed for customized test setups with inputs from external sensors. "The high capacity is required for some of the tests we carry out on cross-laminated timber and load-bearing timber structures. This includes the determination of stresses and strains in the material as well as the strength and deformation properties of joints made with mechanical fasteners such as nails, screws, dowels and bolts," says Prof. Geir I. Vestøl from the Department of Environmental Sciences and Natural Resource Management at NMBU. Up until now, the highest loads occurred when the forces were tested on combined elements made of wood and concrete.

The bending test of construction timber in accordance with EN 408 is carried out on the 250 kN side test stand. Heidenhain linear encoders are used to measure the local deformations. For more detailed analyses of deformations, the department also uses a DIC system from LaVision, which can be used in conjunction with the testing machine. The lateral testing device offers easy access to the specimens and is advantageous, for example, when testing a large number of specimens and when using the DIC system.

The high accuracy is required for tests with low loads on small samples of wood or wood-based materials, such as chipboard and fiberboard. The 10 kN load cell is advantageous when tests with low loads are carried out, for example to determine the Young’s modulus and the bending strength of small clear wood specimens (ISO 13061) or wood-based panels (EN 310).

Researchers also benefit from the performance of the testing machine when determining the tensile strength perpendicular to the plane of the board (EN 319) or the Brinell hardness (EN 1534). Vestøl: "The positioning accuracy and precision are remarkable. And the machine adds very little noise to the data when using the different load cells."

Correct dimensioning of timber connections is crucial for timber structures and buildings, and experimental evaluation is a fundamental activity of the timber laboratory. Timber joints are tested in accordance with the EN 12512 standard for cyclic loads and the EN 26891 standard for static loads.

"The testing machine for timber is incredibly flexible and precise. Because of its high capacity, accuracy and precision, we can test a wide range of specimens. Everything from small specimens of light-colored wood to structural elements can be tested."

Prof. Geir I. Vestøl, Norwegian University of Life Sciences, Faculty of Environmental Sciences and Natural Resource Management