Ypsomed and ZwickRoell Develop a Testing System for On-Body-Devices in accordance with ISO 11608-6 in Record Time

Case Study

- Customer: Ypsomed AG

- Location: Solothurn, Switzerland

- Industry: Medical

- Topic: Development of self-injection systems for OBDS according to ISO 11608-6

March 2024

Ypsomed and ZwickRoell designed and developed an autonomous testing system for on-body-delivery-systems (OBDS). What makes it special: all necessary tests according to ISO 11608-6 are run in a single testing system. This enables the efficient and systematic management of various attributes for OBDS in a single setup, which also reduces factors that influence the results.

Ypsomed AG: leader in the development and manufacturing of injection and infusion systems

With 40 years’ experience, Ypsomed is a leader in the development and manufacture of injection and infusion systems for self-administration of medications. Ypsomed is also a recognized diabetes specialist. As an innovation and technology leader, the company is a strong partner to pharmaceutical and biotech companies for pens, autoinjectors and pump systems for administering liquid medication.

Ypsomed presents and distributes their product portfolio under the umbrella brands mylife Diabetescare directly to patients or via pharmacies and clinics, and under YDS Ypsomed Delivery Systems in the business-to-business sector to pharmaceutical companies. The company is headquartered in Burgdorf, Switzerland, and has a global network of production sites, subsidiaries and sales partners. Worldwide, Ypsomed employs more than 2,200 workers.

The task

On-body-device YpsoDose: achieving progress in the development of testing systems

The development towards the final testing system for Ypsomed—and for potential customers from the pharmaceutical industry—was characterized by decisive steps that influenced the testing system. At Ypsomed, the process began internally with the definition of the test requirements for the on-body delivery system (OBDS). The design of the platform and the test parameters were decisive steps in precisely specifying the particular requirements. The challenges to be overcome included the following factors:

- Determination of the total injection volume for highly viscous medications

- Evaporation of the medication during the injection process

- High measurement accuracy of the injection depth

- Avoidance of static charge during the injection process

- Compatibility with FDA 21 CFR Part 11

The test requirements included the following factors:

- Actuation force of the start button to start the injection process

- Measurement of the injection time

- Measurement of the injection depth

- Measurement of the injection volume/injection profile

- Recording of the injection process with a video camera

- Testing at 37 °C body temperature

With a clearly defined catalog of requirements, Ypsomed searched for a supplier and found ZwickRoell “a partner who provided us with excellent support throughout the entire process,” explains Product Manager Christian Esser-Wiesemann. ZwickRoell’s comprehensive considerations, supported by their in-depth expertise in the medical technology and pharmaceutical industry, ultimately led to both project partners working together as a team to develop an optimized solution.

ZwickRoell also actively addressed the concerns of the Ypsomed laboratory and IT with regard to handling and data management of the testing system and was able to reassure them. Esser-Wiesemann: “This proactive involvement contributed significantly to the development of an effective and optimal solution for the project.”

The ZwickRoell solution

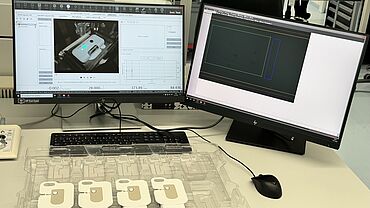

Effective FAT and SAT training: optimal integration for testing systems and data

The factory acceptance tests (FAT) in Ulm and the site acceptance tests (SAT) in Switzerland for the testing system helped the operational teams to familiarize themselves directly with the machine. ZwickRoell provided an effective training program that quickly helped overcome employees’ concerns about the testing system. The teams in the lab learned the skills required to use the equipment in no time. The test results and test data could therefore also be seamlessly integrated into Ypsomed’s data records.

“During tours of the lab, our customers from the pharmaceutical industry particularly appreciate the fact that we have already established a highly standardized test procedure for this new OBDS technology in collaboration with ZwickRoell,” says Esser-Wiesemann.

The result

Precise and consistent test results: the success story with YpsoDose

After testing several thousand YpsoDose devices, Ypsomed developed an in-depth understanding of the behavior of the devices in various scenarios in accordance with ISO 11608-6. The analysis showed that the on-body devices have a remarkably high dosing accuracy at a constant speed. Ypsomed was able to successfully present these findings to its pharmaceutical customers. Esser-Wiesemann: “Analyzing the extensive data sets that were matched to the test attributes was a fascinating process that is now paying off.” Based on careful analysis, the company now achieves reproducible results and can offer this service to customers right from the initial contact. Pharmaceutical customers have great confidence in the test equipment and are enthusiastic about the outstanding performance and versatility that Ypsomed presents.

“The implementation of the test equipment was not only a win for our team, but also made a big impression on our customers. The accuracy of the tests is directly reflected in their satisfaction.”

Christian Esser-Wiesemann, Product Manager YpsoDose, Ypsomed AG