ZSW Ulm Relies on ZwickRoell for Fuel Cell and Battery Research

Case Study

- Customer: Center for Solar Energy and Hydrogen Research (ZSW) in Ulm

- Location: Ulm, Germany

- Industry: Energy

- Topic: ZSW in Ulm tests fuel cells and battery materials

July 2024

The Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) is conducting research at its Ulm site in the Research Factory for Fuel Cells (HyFaB) on the production technology of fuel cells and the characterization of fuel cell materials, in particular gas diffusion layers (GDL), bipolar plates (BPP) and polymer electrolyte membranes (PEM).

HyFaB at ZSW in Ulm

The non-profit foundation Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) was established in 1988 with locations in Stuttgart and Ulm, Germany. The objective: accelerate the translation of basic research findings in the field of renewable energies and electrochemical energy conversion into marketable applications and transfer them to industries.

The ZSW is currently one of the leading German research institutes with around 350 employees and 100 students in Stuttgart and Ulm. The ZSW conducts business-oriented research in the field of sustainable energy technologies, including wind energy, photovoltaics, batteries, hydrogen, fuel cells and policy consultation. The research factory for hydrogen and fuel cells (HyFaB) with a focus on fuel cell manufacturing technology and tests of fuel cells and components as well as a the Center for Battery Research (eLaB) with a focus on lithium and post-lithium technologies are located in Ulm.

HyFaB combines science and industry to advance the industrial production of fuel cells. “Our research ranges from material and component development to system integration, validation and recycling processes. Specializing in PEM fuel cell stacks up to 150 kilowatts, we have been operating our leading European test center with near 50 fully automated test stands up to 250 kilowatts since 2001,” says ZSW board member and Head of the Electrochemical Energy Technologies division, Prof. Dr. Markus Hölzle. In addition, hydrogen filling stations are inspected in Ulm and hydrogen specimens are analyzed in the HyLaB hydrogen quality laboratory set up specifically for this purpose.

The task

Mechanical, electrical and thermal tests on fuel cell materials at HyFaB

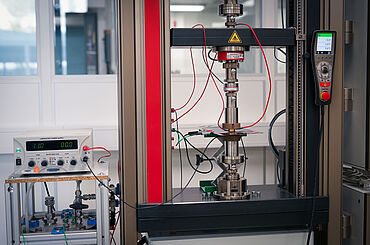

At the Research Factory for Hydrogen and Fuel Cells (HyFaB) in Ulm, ZwickRoell testing machines are mainly used for mechanical, electrical and thermal testing of fuel cell materials. Characterization is relevant in both the through-plane (TP) and in-plane (IP) directions. Pressure, compression, tensile, bending and shear tests are sometimes carried out for this purpose. In the field of production research (ECP), for example, the adhesion of accumulator active material coatings on copper and aluminum foil is tested.

As the gas diffusion layers in particular are very thin (approx. 200 µm) and highly compressible (up to 50 percent at the operating point), there are a number of challenges when carrying out the tests:

The path must be measured very accurately, ideally in the µm range. In addition, thin GDL layers with electrical currents and heat flows typical of fuel cells result in only small potential, or temperature, differences. Testing fuel cell materials also requires special test conditions: Measurements must be carried out at temperatures around 80 °C (and up to 160 °C) and sometimes at relative humidities of up to 100 percent.

The ZwickRoell solution

ZSW Ulm: ZwickRoell AllroundLine and zwickiLine machines in operation

The collaboration between ZSW and ZwickRoell in the characterization of fuel cell materials began with the purchase of an AllroundLine (Z005) in the 5 kN force range, which was later supplemented with a temperature chamber and a videoXtens for displacement measurement. In addition, an AllroundLine with a force range of 10 kN (Z010) and an AllroundLine with a force range of 50 kN (Z050), each with two test areas, were procured. The GDL measuring device developed by ZwickRoell is used in one test area of the Z050.

Two zwickiLine testing machines in the force range of 5 kN are used to test battery materials. One of these testing machines contains a device for testing the adhesion of coatings to carrier foils. The ZSW intends to continue its cooperation with the testing machine manufacturer in the future. “ZwickRoell stands by the reliability and high measurement accuracy of their solutions, as well as excellent customer service. Another advantage for us in particular is the short distance from each other. ZwickRoell is focused on further developing their solutions in our fields, which also benefits us,” says Hölzle.

The result

Commitment to the future of hydrogen technology

The future hydrogen economy is largely dependent on fuel cells, which are regarded as a key technology in this field. As the leading research institute in Germany in the field of hydrogen and fuel cell technology, the ZSW in Ulm plays a key role in the ongoing development of these technologies. ZwickRoell supports this innovative research with their testing machines and will continue to show great interest in the further development of green hydrogen in the future.

“ZwickRoell is actively interested in further developing the test methods for our materials, which presently stands out as a distinctive and uncommon position among other testing machine manufacturers. From our perspective this presents tremendous potential for ongoing development through mutual collaboration.”

Prof. Dr. Markus Hölzle, ZSW Board Member and Head of the Electrochemical Energy Technologies Division

Are you interested in testing solutions for fuel cells or batteries?

We will be happy to advise you with no obligation.

Contact us More information on fuel cell testing More information on battery testing