Seeing Is Believing: Automated vs. Manual Materials Testing

By Bernd Schneider, ZwickRoell Industry Manager – Metals/Automotive

When you consider a major business investment or a shift in processes, it's natural to feel a bit hesitant—and rightly so. Jumping in without thorough research could lead to wasted resources and missed opportunities. This cautious approach is especially important when thinking about automating materials testing processes. Installing and justifying a large, complex robotic system in a tight space can seem daunting and costly. However, it doesn't have to be. With numerous variables and options available, automation solutions can be tailored to fit specific needs, proving that one size rarely fits all. But why automate in the first place? My goal here is to show you the difference in test results when testing manually versus using automation.

Over the years, we’ve dedicated countless hours listening to and understanding our customers by diving deep into their needs and challenges. When we present automation as the perfect solution for their materials testing processes, we often encounter three common misconceptions.

1. Automation is complicated – Yes, it can be! But, more importantly, it doesn’t have to be. The true beauty of today’s flexible automated solutions is that you can start small and scale as needed, solely based on your specific requirements and resources with well tested software packages.

2. Automation is not affordable for us – Automation varies widely in terms of features, capabilities and costs, tailored to meet your needs at any given time, and often provides a quicker return on investment than anticipated.

3. Automation replaces employees – Especially today, with wide-ranging labor shortages, automation actually helps replace monotonous tasks (not people) and frees your limited workforce to apply knowledge and talent in more challenging areas.

With those misconceptions addressed, let me now prove to you the undeniable benefits of automating and how this option can make a difference not only to your financial bottom line, but also the accuracy and therefore credibility of your test results.

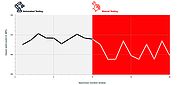

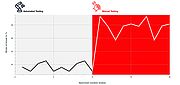

We recently invited prospective customers to bring their samples to be tested in our in-house Xperience center. Here, they tested 10 metal specimens manually and another 10 of the same type of specimens using automation—both using the exact same machine. During the test we measured the Young’s modulus, upper yield point, uniform elongation and strain at break properties of these materials and obtained the following results:

- The prominent peaks and valleys that often occur when testing manually are an indication of parasitic influences that may render results unusable and lead to wasted specimens and therefore increased specimen machining and preparation time and costs.

- The reduced scatter in automated testing ensures more accurate and repeatable results, which is crucial for maintaining high standards in materials testing and reducing unnecessary added—sometimes significant— costs in the specimen preparation process.

By automating your testing processes, you not only enhance the precision of your results but also streamline operations, reduce human error, and ultimately improve your bottom line. Critical employees who are otherwise tied up by monotonous manual processes are now able to rely on their testing systems and focus on key operation tasks.

While the initial investment in automation might seem significant, the long-term benefits far outweigh the costs. Automation provides a scalable, flexible, and reliable solution that can adapt to your specific needs, ensuring that your materials testing processes are both efficient and accurate. So, when it comes to materials testing, seeing truly is believing—automated testing delivers results you can rely on, every time.