- Plastics

- Charpy impact test

- Izod impact test

- Cooled specimens

- ISO 179-1

- ISO 180

- ASTM D256

What is a roboTest H?

The roboTest H is an automated test system for impact tests on plastics according to the Charpy method or Izod method. The robotic testing system can be attached to pendulum impact testers up to 50 joules. Not-instrumented or instrumented pendulum hammers are used based on the requirements.

Plastics can be tested using the Charpy method according to ISO 179-1 or the Izod method to ISO180 or ASTM D256. The automated impact tests are performed at ambient temperature or on tempered specimens.

Specimens are tempered outside of the automated testing system. The plastic specimens are inserted into the magazine compartment with a magazine carriage and fully heated or cooled in an optionally available temperature conditioning box. At a specimen height of 4 mm, the magazine has slots for 20 specimens. Once the required specimen temperature has been reached, the magazine is placed into the robotic testing system.

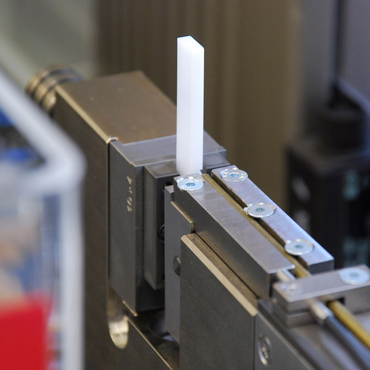

The automated test sequence then conveys the specimens individually out of the magazine via a slide unit. A specimen gripper takes the specimen and positions it in the pendulum impact tester. For the Charpy method, the impact specimen is centered on the specimen supports. For the Izod method, the specimen is gripped in the vertical position.

The impact test is performed within 5 seconds of removing the specimen from the temperature conditioning magazine.

Manual tests can be performed as required.

Advantages

- Operator influences (hand temperature/moisture, off-center or angled specimen insertion etc.) are eliminated resulting in high test-result reproducibility.

- Qualified laboratory staff are relieved of routine activities, allowing them to focus on more complex tasks.

- The machine can be used during idle times (lunch breaks and night shifts), which increases the full capacity and produces faster results.

- The testing system reduces the testing costs per specimen and typically pays for itself within one to two years.

- The system supports reliable documentation and statistical long-term monitoring.

Components and accessories

autoEdition3 automation software

The autoEdition3 automation software is at the core of the robotic testing system. The software controls, regulates and monitors all automated processes, components and devices.

In combination with our testXpert testing software the autoEdition3 automation software delivers traceable and tamper-proof results. Immediately upon starting autoEdition3, the user experiences the benefits of intuitive operation from a look and feel that is consistent with the testXpert user interface.