Robotic testing system roboTest I

For automated impact tests on tempered metal specimens (Charpy) or PE/PP specimens (Charpy/Izod) Download- Metals

- Plastics

- Charpy impact test

- Izod impact test

- Cooled specimens

- ASTM E23

- ISO 148

- ISO 179

- ASTM D256

- ISO 180

What is a roboTest I?

The roboTest I is an automated test system for impact tests on metals or plastics. It can be attached to pendulum impact testers up to 750 joules to automate tempering, feeding and testing of the specimens.

Metals are tested using the Charpy method to ISO 148 or ASTM E23 in a temperature range of -180 to +300 °C (optionally up to +600 °C). The robotic testing system can be used with a 450 joule (only semi-automated) or 750 joule pendulum impact tester.

Plastics are tested using the Charpy method to ISO 179 or ASTM D6110, or optionally using the Izod method to ISO 180 or ASTM D256 in a temperature range of -80 to +100 °C. The roboTest I for plastics can be used with a 25 joule or 50 joule (HIT 25/50) pendulum impact tester.

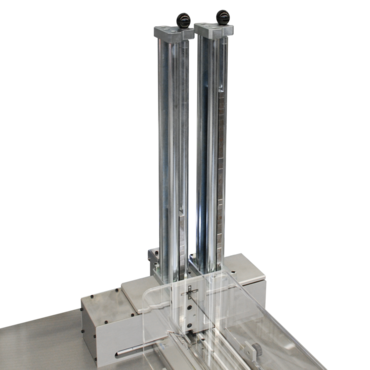

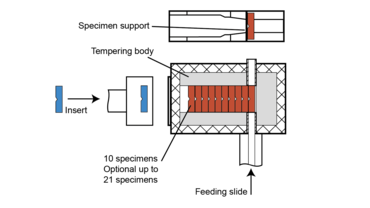

A maximum of 10 specimens are placed and tempered in the temperature conditioning and feed unit. There is no need for an additional temperature conditioning box. Optionally, you can use a temperature conditioning or feed unit with capacity to hold 21 specimens. For the fully automated version, additional non-tempered specimens can be placed in additional stacking magazines. The temperature conditioning device is then filled automatically from these magazines.

Specimen slide carriers facilitate insertion and removal of specimens into/from the temperature conditioning device, either manually (semi-automatic version) or automatically (fully automatic version).

After reaching the required temperature, the foremost specimen is pushed out of the temperature conditioning device into its test position, where it is automatically aligned and impacted. The impact test is performed within 5 seconds of removing the specimen from the temperature conditioning device.

Optional components including a barcode reader (2D) and HOST connection complete the system.

Manual tests can be performed as required.

Videos

Advantages

- Operator influences (hand temperature/moisture, off-center or angled specimen insertion etc.) are eliminated resulting in high test-result reproducibility.

- Qualified laboratory staff are relieved of routine activities, allowing them to focus on more complex tasks.

- The machine can be used during idle times (lunch breaks and night shifts), which increases the full capacity and produces faster results.

- The testing system reduces the testing costs per specimen and typically pays for itself within one to two years.

- The system supports reliable documentation and statistical long-term monitoring.

Accessories for metals testing

autoEdition3 automation software

The autoEdition3 automation software is at the core of the robotic testing system. The software controls, regulates and monitors all automated processes, components and devices.

In combination with our testXpert testing software the autoEdition3 automation software delivers traceable and tamper-proof results. Immediately upon starting autoEdition3, the user experiences the benefits of intuitive operation from a look and feel that is consistent with the testXpert user interface.