Lightweight Robot roboTest N

Automated function testing of simple applications in small series Download- Plastics

- Metals

- Medical

- Components

- Tensile

- Flexure

- Compression

- Impact

- lightweight specimens

- Small series

- ISO 6892

- ISO 527-2

- ISO 178

- ASTM D638

What is a roboTest N?

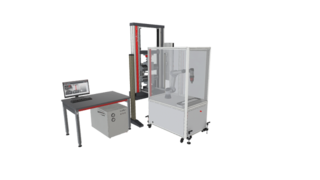

The roboTest N is a testing system with a lightweight robot for tests on plastics, sheet metals, and components, or for automated function tests of medical devices such as autoinjectors, pen injectors and syringes. This system offers you a cost-effective and smart testing assistant for you laboratory, especially suited for simple pick and place applications starting with small series of 10 specimens.

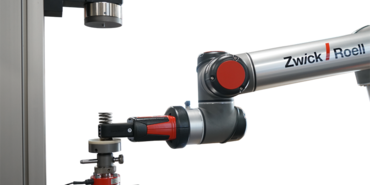

The roboTest N can autonomously test up to 40 specimens in a tensile or flexure test. Automated function tests can also be performed with this system. Through flexible attachment, the testing system can be quickly and easily used on different testing machines.

The specimens to be tested are inserted in a magazine. The gripper removes the specimens from the magazine and conveys them to the testing machine. The specimen is gripped in the and the test starts fully automatically. Optionally, you can integrate more stations such as a cross-section measuring device or an ID code scanner.

Manual tests can be performed as required by uncoupling the specimen feeding system.

The roboTest N can also be used for automated hardness testing or roughness measurement. In this case, the feeding system is mounted directly to the hardness tester or roughness measurement device. There is no need for a materials testing machine.

roboTest N & Industry 4.0

Digitalization, buzzword “Industry 4.0”, is still the main industry topic worldwide. For years, permanently installed robotic testing systems in test labs have been performing one successful test after another. They relieve qualified personnel from tedious and boring series testing, whether it be 100 specimens or 1000 specimens. With the roboTest N, ZwickRoell has elevated this concept to new heights: starting immediately, the smart lightweight robot can be used to quickly and easily automate small series tests.

Constantly changing series with small numbers of specimens can often not be efficiently processed with a robotic testing system: the setup is too costly, both in terms of hardware and software. With the roboTest N, a collaborating robotic system for materials and component testing, even small test series can be processed fully automatically. The cobot is fully integrated into the ZwickRoell autoEdition3 automation software, and can be used entirely without a robot operator panel. Special knowledge of robot programming or operations is not required. The roboTest N easily and flexibly supports employees in the testing laboratory with monotonous or time-consuming tests. Integration of company-owned specimen magazines that were manufactured through 3D printing processes, for example, underlines the adaptability of the system and where applicable, extends workday efficiency based on the capacity of the magazine.

With its compact, space-saving design, the roboTest N is easy to retrofit in existing test laboratories, especially since its safe design doe not require elaborate operator protection measures.

Videos with roboTest N application examples

Advantages of the roboTest N

- ZwickRoell has over 35 years of experience and expertise, gained while supplying more than 700 automated testing systems worldwide.

- Due to the complete integration of the lightweight robot into the ZwickRoell software environment, robot programming knowledge is not required for operation.

- The intuitive user interface for roboTest N in autoEdition 3 also ensures flexible use for future testing applications.

- With force-controlled drive axes, the roboTest N requires a smaller installation location than conventional industrial robots, while maintaining the same level of safety.

autoEdition3 automation software

The autoEdition3 automation software is at the core of the robotic testing system. The software controls, regulates and monitors all automated processes, components and devices.

In combination with our testXpert testing software the autoEdition3 automation software delivers traceable and tamper-proof results. Immediately upon starting autoEdition3, the user experiences the benefits of intuitive operation from a look and feel that is consistent with the testXpert user interface.

SmartWizard configuration interface

A SmartWizard software assistant option is available for the roboTest N standard package for tensile tests on plastics or flexure tests on plastics, with which the operator can easily adapt the robotic testing system to changing specimen shapes or test sequences.

It offers the freedom and flexibility you need to be successful in a world of fast and continuously evolving requirements.

Your testing system is ready to learn!