High-Speed Testing Machine HTM

Download- 25 kN - 160 kN

- 12 m/s - 20 m/s

- High-speed tensile tests

- Puncture tests

- ISO 6603-2

- ASTM D3763-02

- ISO26203-2

- SEP 1230

- ESIS P7-00

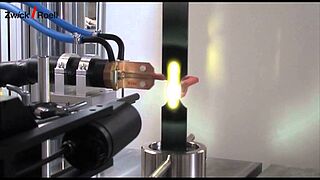

High strain rates and crash simulation

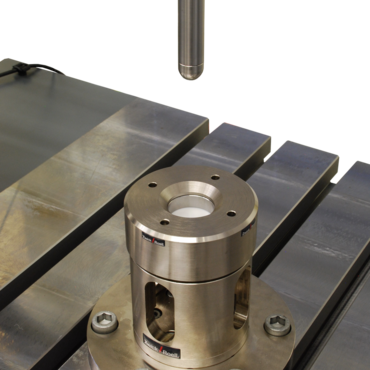

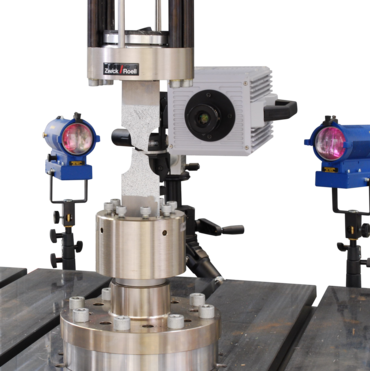

The HTM series servohydraulic high-speed testing machines allow you to determine strain-rate-dependent characteristic values over a wide speed range. Uses for machine include puncture tests and high-speed tensile tests, as well as peel, and shear tests at high speeds. Crash tests on components can also be performed in conjunction with the optional T-slotted platform.

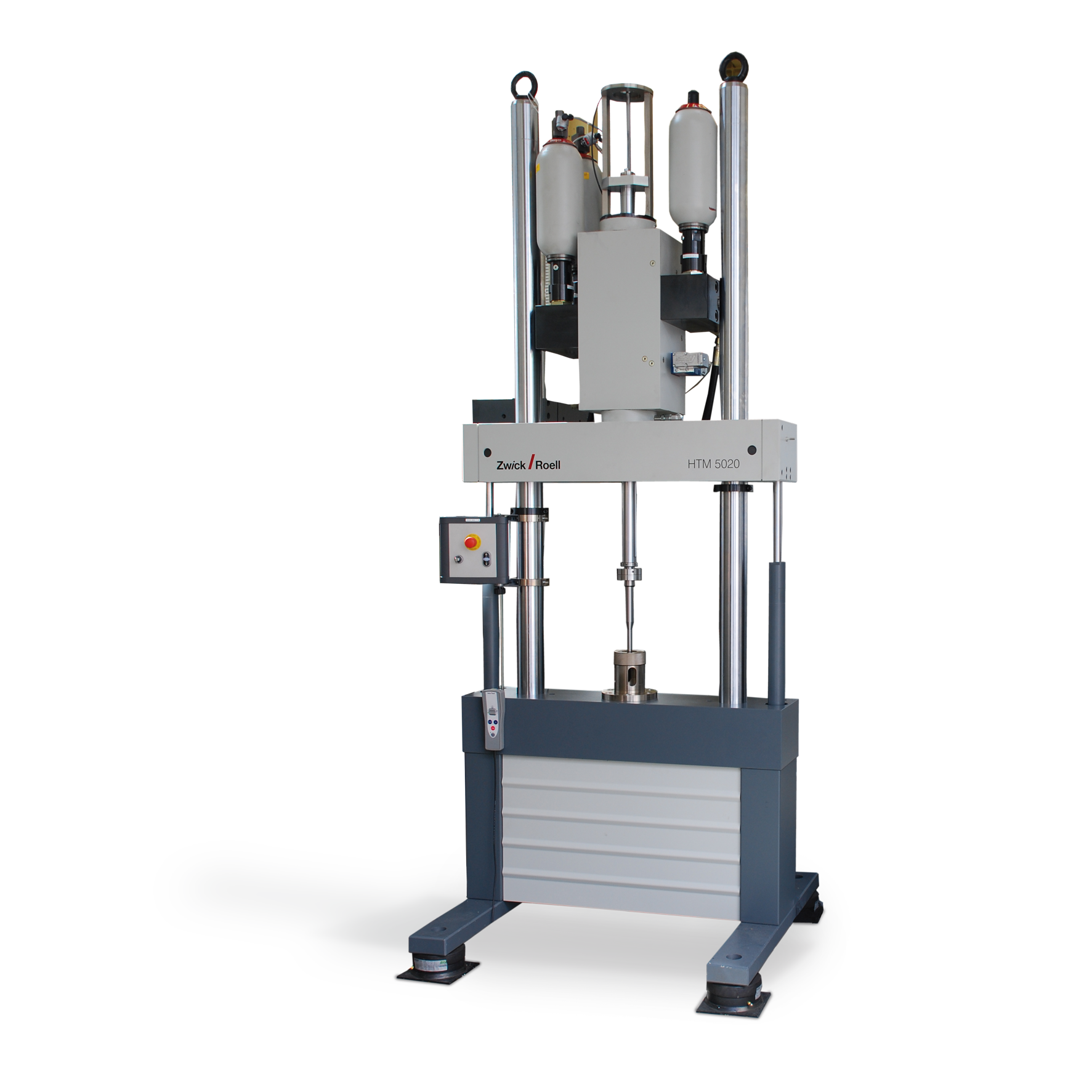

The HTM series is available in various versions with maximum test loads of 25 kN, 50 kN, 80 kN or 160 kN.

The fracture behavior of many materials is dependent on, among other things, the loading rate. Relevant data and constitutive equations are required for the numerical calculation of crash safety. With a maximum piston speed of 20 m/sec, high-speed testing machines can be used for crash simulation. For testing, the speed can be selected from a wide range, starting very slow and going up to maximum speed.

High-speed testing machines form a complete system with all components, including the hydraulic power pack, test frame with high-speed testing actuator and safety housing, fast testControl measurement and control electronics with PC and testXpert testing software—perfectly coordinated and integrated.

Technical overview

| HTM 2512 | HTM 5020 | HTM 8020 | HTM 16020 | |

|---|---|---|---|---|

|  |  |  | |

| Force | 25 kN | 50 kN | 80 kN | 160 kN |

| Piston speed, max. | 12 m/s | 20 m/s | 20 m/s | 20 m/s |

| Installation of testing actuator | Lower crosshead | Upper crosshead | Upper crosshead | Upper crosshead |

| T-slotted platform | No | Optional | Optional | Yes |

| Typical Applications |

|

|

|

|

| Type HTM | 2512 | |

| Nominal force | 25 | kN |

| Test load Fmax | 25 | kN |

| Piston speed | 12/0.001 | max/min m/s |

| Piston stroke | ||

| Total | 300 | mm |

| Usable | 250 | mm |

| Total piston stroke | 250 | mm |

| End cushioning | 2x25 | mm |

| Effective stroke | 200 | mm |

| Nominal pressure | 280 | bar |

| Actuator design | Double-rod actuator with hydrostatic bearings | |

| Force measurement | Piezo-electric | |

| Travel measurement | Incremental | |

| Dimensions 1 | ||

| A - height of test frame | 2665 | mm |

| AK - topple measure for installation | 2850 | mm |

| Max. width of test frame | 1090 | mm |

| Max. depth of test frame | 750 | mm |

| D - Distance between columns | 565 | mm |

| E - Column diameter | 80 | mm |

| F - Height of upper edge of lower crosshead | 1000 | mm |

| G - Max. test area height | 1370 | mm |

| H - crosshead adjustment path | 1000 | mm |

| Weight | 1600 | kg |

| Item No. | ||

| HTM 2512 load frame | 046216 | |

| HTM 2512 actuator | 014113 | |

| HTM2512 safety device | 1014336 | |

| HTM 2512 safety device (for TEE) | 031189 | |

| Required accessories2 | ||

| HTM hydraulic distribution unit A-I | 072573 | |

| Leak oil drain pump | 924785 | |

- Dimensions without safety housing

- The machine can be connected to a central 280 bar hydraulic supply or to a dedicated hydraulic power unit.

| Description | Value | |

| Type HTM | 5020 | |

| Nominal force | 50 | kN |

| Piston speed | 20 / 0.001 | max/min m/s |

| Total piston stroke | 350 | mm |

| End cushioning | 2 x 50 | mm |

| Effective stroke | 250 | mm |

| Nominal pressure | 280 | bar |

| Actuator design | Double-rod actuator with hydrostatic bearings | |

| Force measurement | Piezo-electric | |

| Displacement transducer | Incremental | |

| Dimensions 1 | ||

| A - Height of test frame | 3000 | mm |

| AK - topple measure for installation | 3160 | mm |

| AG350 - Overall height with actuator | 3990 | mm |

| Max. width of test frame | 1200 | mm |

| Max. depth of test frame | 1130 | mm |

| D - Distance between columns | 670 | mm |

| E - Column diameter | 100 | mm |

| F - Height of upper edge of lower crosshead | 890 | mm |

| G - Max. test area height | 1705 | mm |

| H - Max. working test area height | 1670 | mm |

| J - Crosshead displacement range | 1150 | mm |

| Weight with T-slot platform | 2900 | kg |

| Item No. | ||

| HTM load frame with T-slot platform | 028320 | |

| HTM actuator | 009522 | |

| HTM safety device | 935683 | |

| Required accessories2 | ||

| HTM hydraulic distribution unit B-I with hose-holder | 072574 | |

| Leak oil drain pump | 924785 | |

- Dimensions without safety housing

- The machine can be connected to a central 280 bar hydraulic supply or to a dedicated hydraulic power unit.

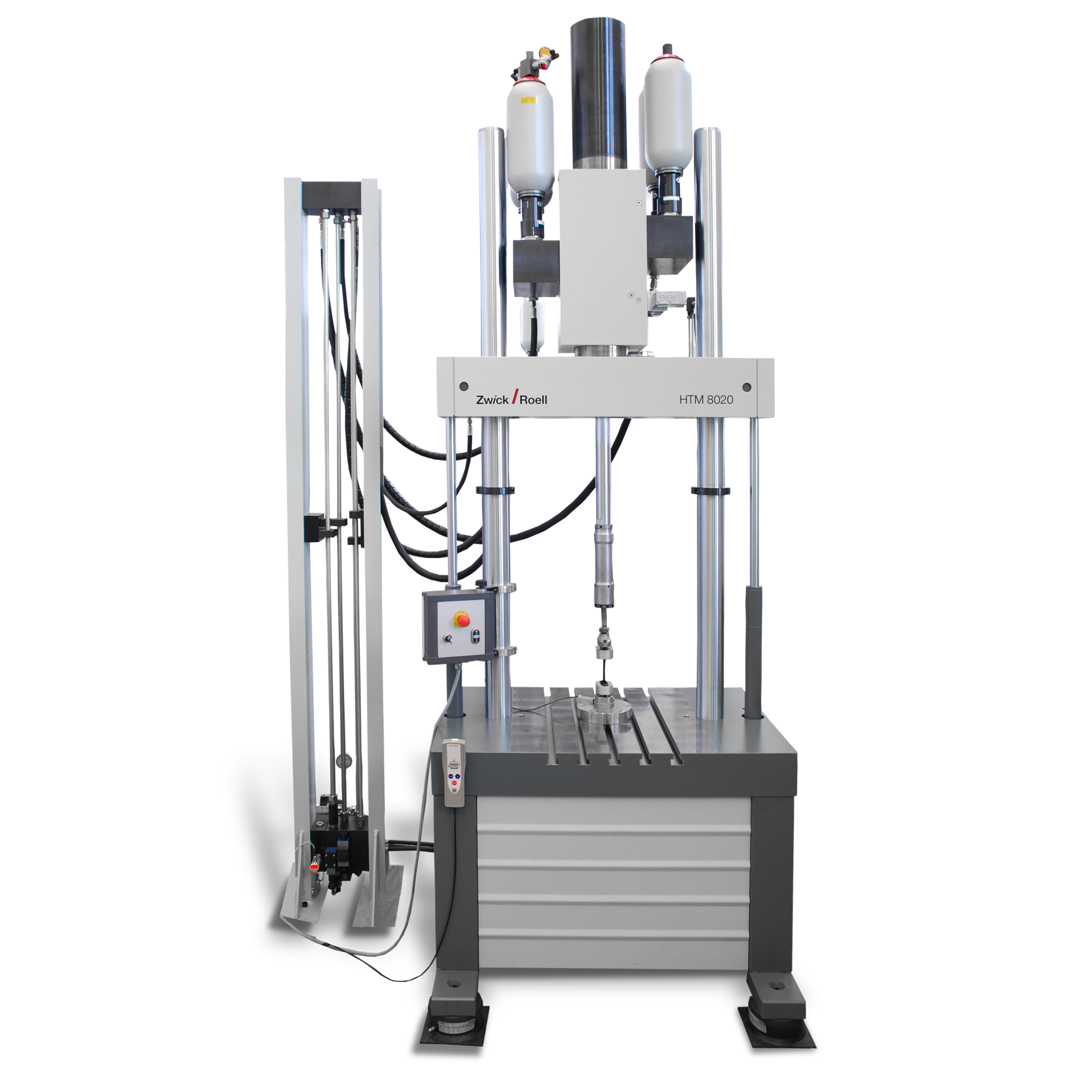

| Type HTM | 8020 | |

| Nominal force | 80 | kN |

| Piston speed | 20 / 0.001 | max/min m/s |

| Total piston stroke | 350 | mm |

| End cushioning | 2 x 50 | mm |

| Effective stroke | 250 | mm |

| Nominal pressure | 280 | bar |

| Actuator design | Double-rod actuator with hydrostatic bearings | |

| Force measurement | Piezo-electric | |

| Displacement transducer | Incremental | |

| Dimensions 1 | ||

| A - Height of test frame | 3000 | mm |

| AK - topple measure for installation | 3160 | mm |

| AG350 - Overall height with actuator | 3990 | mm |

| Max. width of test frame | 1200 | mm |

| Max. depth of test frame | 1130 | mm |

| D - Distance between columns | 670 | mm |

| E - Column diameter | 100 | mm |

| F - Height of upper edge of lower crosshead | 890 | mm |

| G - Max. test area height | 1705 | mm |

| H - Max. working test area height | 1670 | mm |

| J - Crosshead displacement range | 1150 | mm |

| Weight with T-slot platform | 3000 | kg |

| Item No. | ||

| HTM load frame with T-slot platform | 1038693 | |

| HTM actuator | 022354 | |

| HTM safety device | 022356 | |

| Required accessories2 | ||

| HTM hydraulic distribution unit B-I with hose-holder | 072574 | |

| Leak oil drain pump | 924785 | |

- Dimensions without safety housing

- The machine can be connected to a central 280 bar hydraulic supply or to a dedicated hydraulic power unit.

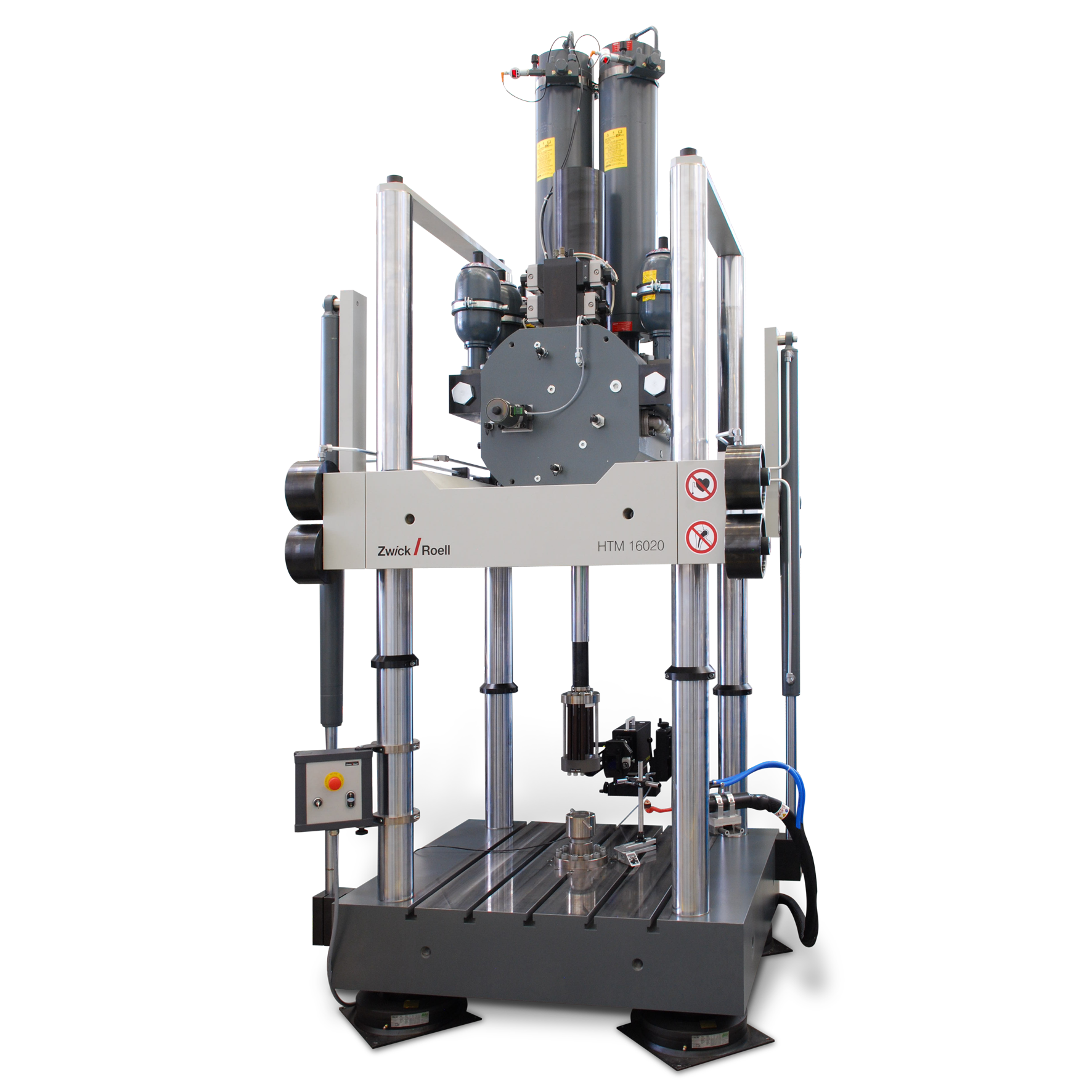

| Type HTM | 16020 | |

| Nominal force, static | 160 | kN |

| Piston speed | 20 / 0.001 | max/min m/s |

| Total piston stroke | 400 | mm |

| End cushioning | 2 x 50 | mm |

| Effective stroke | 300 | mm |

| Nominal pressure | 280 | bar |

| Actuator design | Double-rod actuator with hydrostatic bearings | |

| Force measurement | Piezo-electric | |

| Displacement transducer | Incremental | |

| T-slots | To DIN650-22H8, spacing 200 mm | |

| Dimensions 1 | ||

| A - Min. height of test frame | 2793 | mm |

| AK - Tilted dimension for installation | 3552 | mm |

| AG400 - Overall height with actuator | 4264 | mm |

| Max. width of test frame | 1560 | mm |

| Max. depth of test frame | 1353 | mm |

| D - Distance between columns | 880 | mm |

| E - Column diameter | 120 | mm |

| F - Height of upper edge of lower crosshead | 432 | mm |

| G - Max. test area height | 1800 | mm |

| H - Max. working test area height | 1718 | mm |

| J - Crosshead displacement range | 1200 | mm |

| Weight with actuator | 13000 | kg |

| Item No. | ||

| HTM load frame with T-slot platform | 026388 | |

| HTM actuator | 026390 | |

| HTM safety device | 026392 | |

| Required accessories2 | ||

| HTM hydraulic distribution unit B-II with hose-holder | 072577 | |

| 2x leak oil drain pump | 924785 | |

- Dimensions without safety housing and pipe brackets

- The machine can be connected to a central 280 bar hydraulic supply or to a dedicated hydraulic power unit.

Common Tests

Particular uses for HTM high-speed testing machines include puncture tests and high-speed tensile tests, as well as peel and shear tests at high test speeds. They are ideally suited for the determination of the material behavior under crash loading. Their maximum piston speed of 20 m/s (72 km/h) is faster than the 64 km/h test speed used in the Euro NCAP frontal impact crash test.