The Simple Rockwell Hardness Tester

N3

Standards

- ISO 6508

- ASTM E18

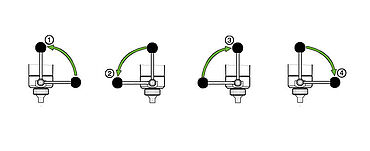

Test methods

- Rockwell

- HBT

- HVT

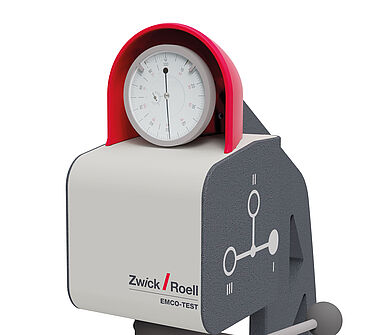

N3 - simple Rockwell hardness test

The N3 Rockwell hardness tester is ideal for simple and quick Rockwell tests in accordance with ISO 6508 and ASTM E18. It is also possible to test Brinell (HBT) and Vickers (HVT) using the differential depth method. The instrument is characterized by high precision and reliability and is ideal for workshop use. Thanks to its compact design and the absence of electronic components (no power supply required), it can be set up and used with a high level of flexibility. It is suitable for all sectors of the metalworking industry.

Hardness test methods

- In addition to the entire Rockwell range, the N3A also covers the Brinell and Vickers methods in depth in a load range of 15-187.5 kg.

- Carbon testing is also possible.

N3A technical data

| Load range | 15 ... 187.5 kg |

| Clamping insert outer diameter (standard) | Ø 15 mm |

| Clamping insert inner diameter (standard) | Ø 8 mm |

| Height adjustment | by manual dial |

| Test height (N1A unit and spring sleeves) | 285 mm |

| Throat | 170 mm |

| Max. work piece weight | 260 mm |

| Dimensions W x H x D | 205 x 830 x 470 mm |

| Weight of basic device | 35 kg |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |