Test methods

- Shore A, B, C, D,…

Handling

- Portable

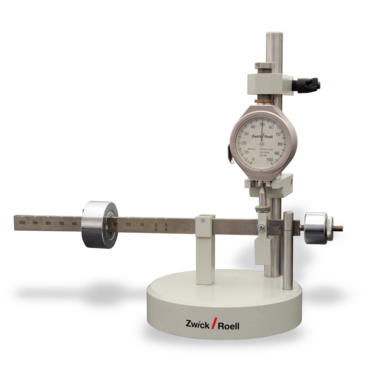

- Stationary

Standards

- ISO 48-4

- ASTM D2240

- ISO 868

Analog and digital durometer

The Shore hardness testers/durometers are used for determining the hardness of plastics and rubber according to standards ISO 48-4, ASTM D2240, ISO 868, NFT 51109 and BS 903 Part A26. For on-site testing on the product, analog versions with and without drag-pointer are available. The Shore hardness testers with drag pointers simplify testing, particularly in difficult-to-access locations, as the pointer still indicates the measured value after the test. The digital Shore hardness testers can be connected to testXpert III via data transfer.