Test methods

- Vickers

- Knoop

- Brinell

- Rockwell

- Carbon testing

- Plastics testing

Test load

- 0.3 - 250 kg

- 3 - 3,000 kg

- Optionally from 0.01 kg

Versions

- Handwheel operated version

- Motorized Z-axis

- Fully automated component positioning

- Different test heights and load ranges

Standards

- ISO 6506

- ISO 6507

- ISO 4545

- ASTM E384

- ASTM E92

- ASTM E10

- ISO 6508

- ASTM E18

- DIN 51917

- ISO 2039

Hardness Testing Methods – Deep Insights with the Right Test Method

- Depending on the model, load ranges of 0.3-250 kg or 3-3,000 kg (optionally from 10 g) are covered.

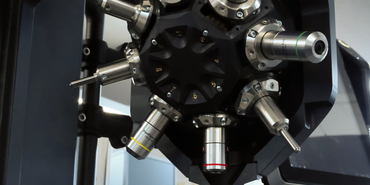

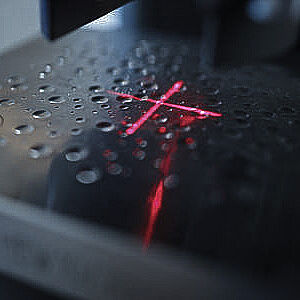

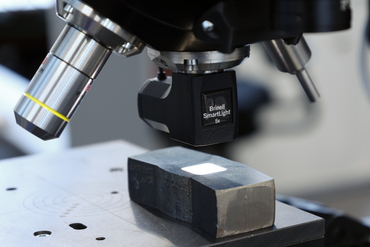

- The macro hardness tester covers optical methods and differential-depth methods for your hardness testing applications. This includes Vickers, Brinell, Knoop or Rockwell.

- Different lenses are based on material hardness and test load and display your test results in high resolution. Your test results can be converted into other hardness values in accordance with industry standards.

| Load range | 0.3-250 kg (optionally from 10 g) |

| Max. speed, Z-axis | - |

| Dimensions (WxDxH) | 305x680x1271.5 (mm) |

| Weight | 240 kg |

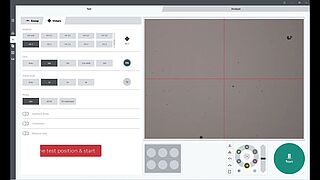

| Operation | 15.6" touch panel PC |

| Max. test height | 220 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120/50 W |

| Test table (W x D) | Ø 90 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 0.3-250 kg (optionally from 10 g) |

| Max. speed, Z-axis | 25 mm/s |

| Dimensions (WxDxH) | 305x680x1166.5 (mm) |

| Weight | 260 kg |

| Operation | 15.6" touch panel PC |

| Max. test height | 175 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 720/100 W |

| Test table (W x D) | Ø 90 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

|

| Load range | 3-3,000 kg (optionally from 10 g) |

| Dimensions (WxDxH) | 360x837x1517.5 (mm) |

| Weight | 405 kg |

| Operation | 15.6" touch panel PC |

| Max. test height | 350 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120/50 W |

| Test table (W x D) | Ø 90 mm + 447x370mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 3-3,000 kg (optionally from 10 g) |

| Max. speed, Z-axis | 25 mm/s |

| Operation | 15.6" touch panel PC |

| Dimensions (WxDxH) | 360x837x1545 (mm) |

| Weight | 425 kg |

| Max. test height | 300 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 720/100 W |

| Test table (W x D) | Ø 90 mm + 447x370mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 3-3,000 kg (optionally from 10 g) |

| Max. speed, Z-axis | 25 mm/s |

| Operation | External PC with monitor, not included |

| Dimensions (WxDxH) | 850x837x1545 (mm) |

| Weight | 450 kg |

| Max. test height | 180 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 600/100 W |

| Test table (W x D) | 440 x 250 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 50 kg |

| Protection class to EN 60529 | IP20 |