Universal Hardness Tester

Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing. To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3-3,000 kg (optionally from 10 g) for tests on many different material and component geometries in a variety of industries.

ZwickRoell universal hardness testing machines test according to valid industry standards, including ISO 6506, ASTM E10 (Brinell), ISO 6507, ASTM E384, ASTM E92 (Vickers), ISO 6508, ASTME18 (Rockwell), ISO 4545 (Knoop), DIN51917 (carbon testing) as well as ISO 2039 (plastics testing).

Hardness testing not only applies to the determination of material characteristics in terms of hardness and forming processes, it is also used for quick and effective testing during production processes to ensure that the material meets the requirements and behaves optimally according to its intended application. Our universal hardness testing equipment ensures reliable test results in the lab, as well as in raw production environments.

Universal hardness tester overview Brinell hardness tester Test methods / standards Consultation request

Universal hardness tester overview

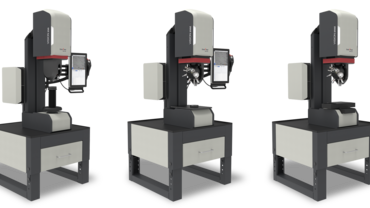

The various models of the VisionLine are software-controlled universal hardness testers with automated load application (closed loop) and fully automatic test point evaluation.

Our software-controlled instruments provide a variety of functions, including the use of templates, user-defined specimen grips, high resolution camera systems and electronically controlled load application. The fully automatic instruments can also be used to create a wide range of hardness curves and hardness mapping.

One significant benefit of universal hardness testing machines comes from the addition of a tool changing system (revolver), since these enable you to quickly change between individual test methods, without undergoing extensive machine conversion efforts.

Brinell hardness testing instrument

The method developed by Swedish engineer Johan August Brinell in 1900 is a worldwide implemented test method used to determine the hardness of soft to medium-hard metals (summary table of Brinell methods and materials to ISO 6506). The Brinell method can be used to test irregular microstructures, such as cast iron, because the large ball comes into contact with many crystals (different structural components of the material), thereby forming a mechanical average value.

A Brinell hardness tester must be able to accurately measure the hardness on materials of different hardness grades without damaging or deforming the specimen.

With our universal hardness testers, we cover the Brinell method extensively. We evaluate the indentation created with a hardmetal ball using a high-quality optical system.

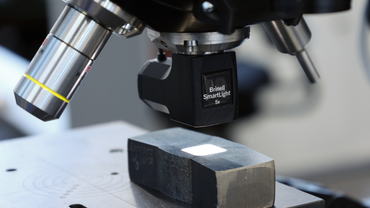

Since Brinell hardness testing has always been a challenge when testing very soft metals and difficult surfaces, we developed lenses with innovative illumination. With the special Brinell SmartLight lenses for our universal hardness testers, the edges of the indentation are much easier to detect despite significant deformation (bulging), further improving the precision of the evaluation.

Advantages of our ZwickRoell universal hardness testers

In the development of our ZwickRoell universal hardness testers we specifically focus on high precision and durability, easy and intuitive operation that minimizes operational errors, a future-proof testing software solution, easy access to the test area and extensive flexibility when it comes to specimen gripping.

How does a universal tester work?

A universal hardness testing machine uses either a pyramid-shaped diamond (Vickers), diamond cone (Rockwell) or hardmetal ball (Brinell) indenter to create an indentation in the material to be tested.

We differentiate between two common methods:

- Differential depth method (Rockwell): the distance between the main load and the preload is determined. The greater the distance, the softer the metal.

- Optical method (Brinell, Vickers, Knoop): the test piece is indented with an indenter and then the diagonals, or diameters are evaluated with the corresponding lens.

The level of automation determines the extent of the tasks that can be performed, ranging from individual measurements to multi-part tests or hardness curves.

Frequently asked questions about our hardness testers

A universal hardness tester is a hardness testing machine that covers various hardness test methods, including Brinell, Vickers and Rockwell. To cover these methods, a wide load range is required.

A typical universal hardness tester consists of a load application feature, an indenter, a test anvil and a system for optical evaluation of the specimen indentations, as well as a depth measurement system. ZwickRoell universal hardness testing machines are software-controlled instruments that evaluate the test indentation fully automatically.

The test methods are categorized into optical test methods (Vickers, Brinell, Knoop) and differential depth methods (Rockwell). For the optical methods, an indentation is made in the material with a diamond pyramid or hardmetal ball and evaluated with an optical system. For the differential depth method, a diamond cone or tungsten carbide ball is pressed into the material to be tested and the indentation depth is measured.

A Brinell hardness tester is used to determine the hardness of soft to medium-hard metals according to the Brinell method (ISO 6506, ASTM E10). A hardmetal ball is pressed into a test piece with a predetermined force. The indentation that is left behind is then measured optically and the Brinell hardness is determined.

Particular challenges come into play with very soft metals and difficult surfaces. ZwickRoell Brinell hardness testing instruments use a special lens with which it is much easier to recognize the edges of the indentation despite significant deformation (bulging), further improving the precision of the evaluation.