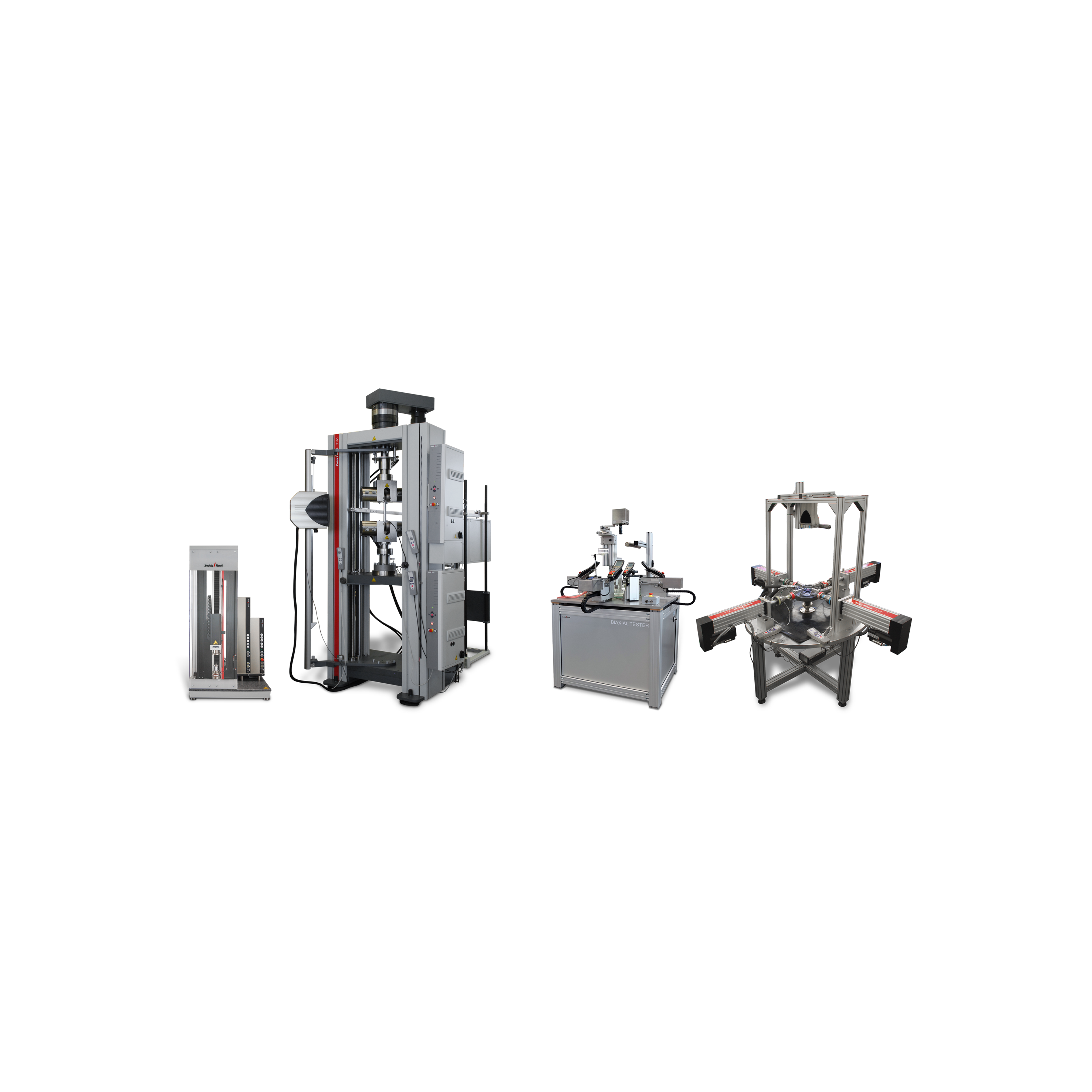

Static Materials Testing Machines

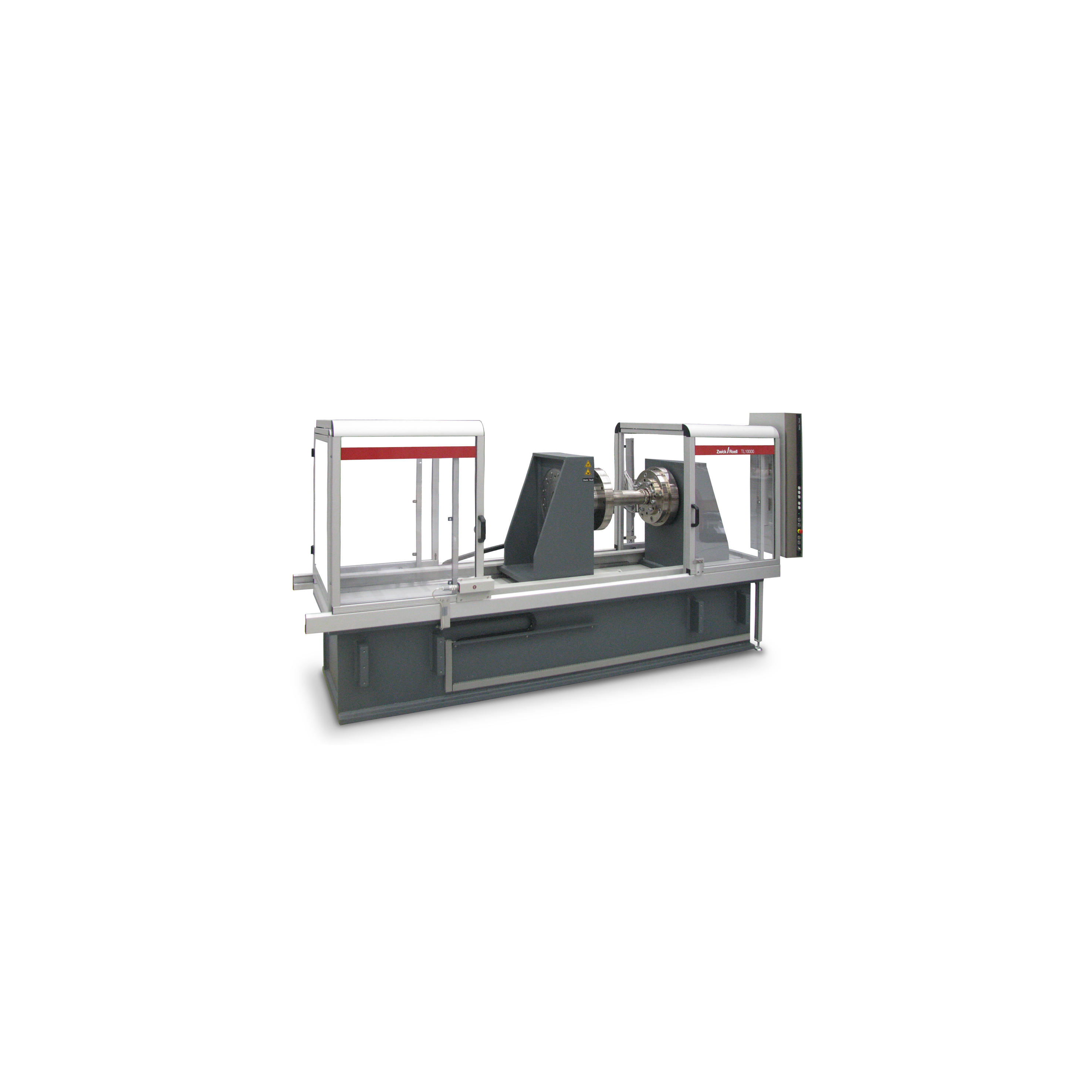

ZwickRoell is a worldwide leading supplier of static materials testing machines, specially designed for tensile, compression and flexure tests, as well as shear and torsion tests.

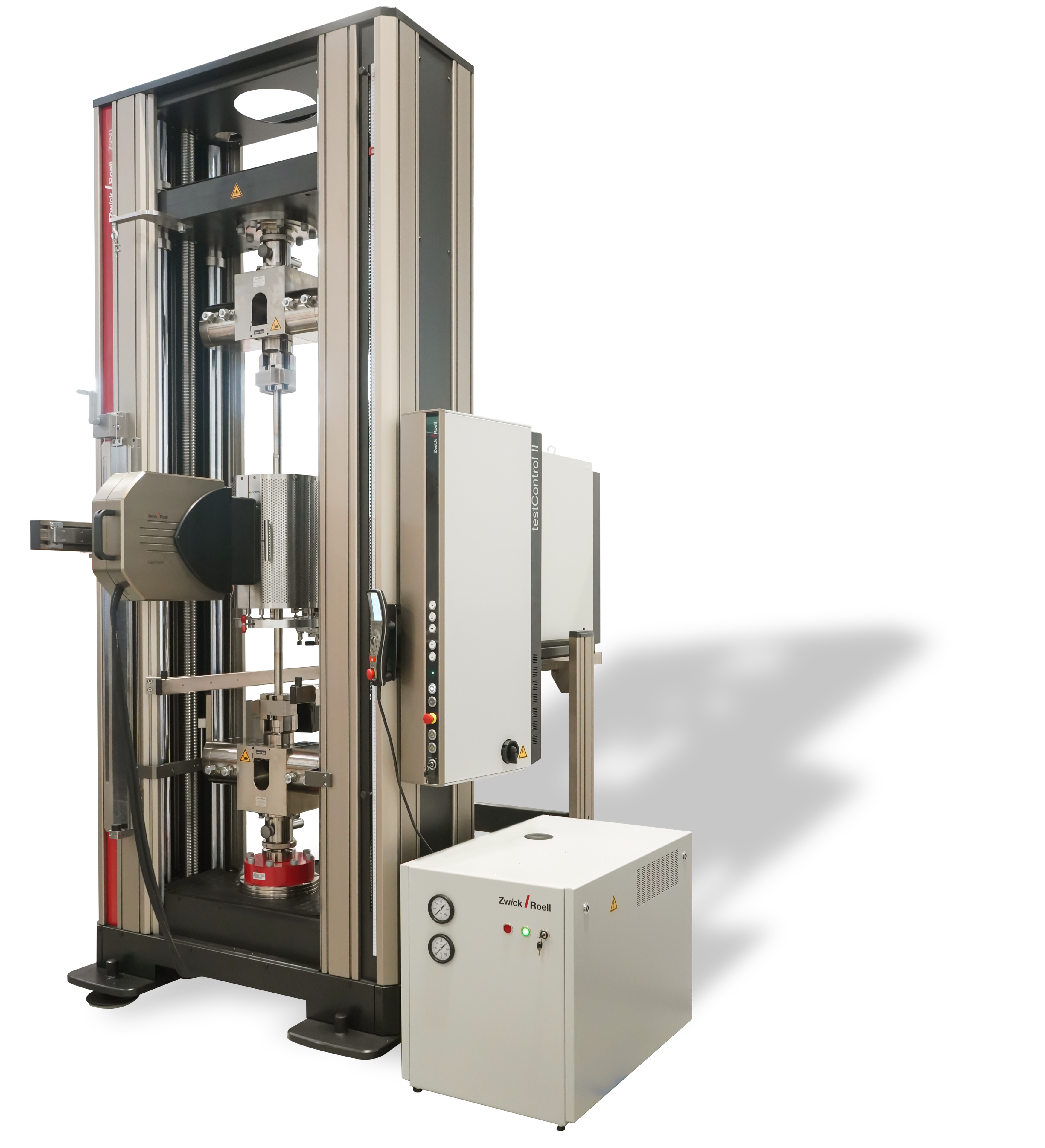

Our static materials testing machines are ideal for testing applications in all areas, whether it be quality control or research projects, delivering outstanding performance in challenging materials and component testing situations.

Developed by our experts, these materials testing machines for the 200 N to 2,500 kN force range offer a wide span of test strokes and speeds and feature high-quality load frames combined with intelligent drive systems.

Products Application examples Testing software and electronics Accessories Customer projects

testXpert III testing software & testControl II electronics - a powerful combination

testControl, our sophisticated measurement and control electronics system is the heart of each testing machine. It is easy to operate and extremely reliable. testXpert is our intuitive testing software, specifically designed for materials testing and components testing. It can intelligently adapt to each task and guarantees maximum accuracy and reproducibility in test results. testXpert and testControl work together to ensure efficient and safe operation of the materials testing machine.

Flexible and simple integration of accessories for all materials testing machines

At ZwickRoell, quality and reliability means realizing our customers’ requirements—and we are able to achieve this through our flexible, well designed machines, the reliable test results we deliver and in the high quality standards that apply to all our testing machines and our wide range of accessories.