Kappa Multistation

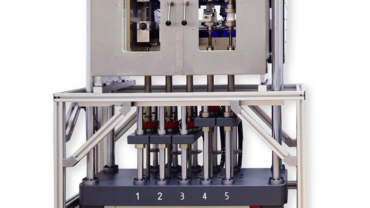

Electromechanical creep testing machine with up to six individually controllable test axes Download

Test load

- Up to 10 kN/axis

Temperature range

- -40 to +250°C

Type of test

- Creep

- Stress Relax

- SIM, FNCT

- Tensile

- Compression

- Flexure

Standards

- ISO 899-1

- ISO 899-2

- ASTM D2990

- ISO 3384-1

- ISO 16770

- ISO 527

- ASTM D638

The compact multi-axis testing system for a wide spectrum of specimens and test types up to 10,000 hours

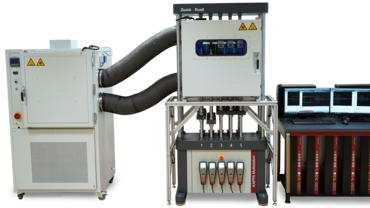

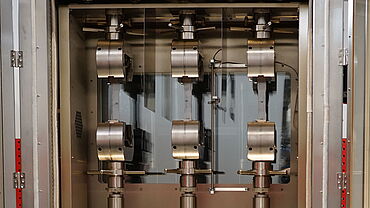

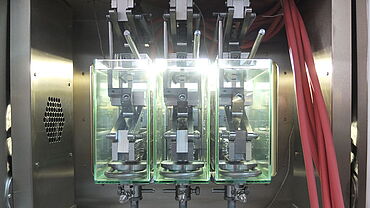

The Kappa Multistation is a compact and flexible electromechanical creep testing machine with up to six individually controlled load axes. This cost and space efficient testing system is ideal for a wide spectrum of specimen materials, and is considered the specialist for creep tests on plastics and composites. The flexible testing system is ideal for changing test tasks in modern development and testing laboratories, because it can be used for applications at ambient temperature, under low and elevated temperatures as well as in humidity conditions:

- Creep tests with constant load (tensile, flexure and compression tests)

- Creep tests up to break

- Creep rupture

- Stress rupture - Stress relaxation tests with constant elongation

- Force and strain controlled tests (closed loop) with force, strain and temperature sequences (stepless/in blocks)

- Tests with flexible loads, e.g. constant force increase rates

- Time-lapse testing methods, e.g. SIM, TTS, SSM

- Quasi-static tests can also be performed with this testing machine

Technical overview

| Type | Kappa Multistation |

| Test load per test axis, max. Fmax | 10 kN |

| Number of test axes | max. 6 |

| Distance between the axes | 105 mm |

| Crosshead travel, max. | 200 mm |

| Lateral guidance of the moving crosshead via precision bearings on two hard-chromed columns | Diameter 30 mm |

| Test speed range | 0,001 mm/h to 100 mm/min |

| Return speed | 100 mm/min |

| Test speed accuracy (measured over an interval of min. 5 s or 10 mm travel) | < ±0,1 % |

| Position transducer travel resolution | 0.0025 µm |

| Testing system dimensions | |

| Width | 1197 mm |

| Depth | 1233 mm |

| Height | 2116 mm |

| Weight | 1200 kg |

| Supply voltage | 230 VAC |

| Installed power load per test axis | 400 VA |

| Type | Kappa Multistation |

| Test load per test axis, max. Fmax | 10 kN |

| Number of test axes | max. 6 |

| Distance between the axes | 105 mm |

| Crosshead travel, max. | 200 mm |

| Lateral guidance of the moving crosshead via precision bearings on two hard-chromed columns | Diameter 30 mm |

| Test speed range | 0,001 mm/h to 100 mm/min |

| Return speed | 100 mm/min |

| Test speed accuracy (measured over an interval of min. 5 s or 10 mm travel) | < ±0,1 % |

| Position transducer travel resolution | 0.0025 µm |

| Testing system dimensions | |

| Width | 1197 mm |

| Depth | 1233 mm |

| Height | 2116 mm |

| Weight | 1200 kg |

| Supply voltage | 230 VAC |

| Installed power load per test axis | 400 VA |

Interesting equipment variations at a glance

More customers rely on a Kappa Multistation

EMS-GRIVORY Europe, Switzerland

EMS-GRIVORY Europe is one of the leading specialists for high-performance polyamides. At the main location in Domat/Ems, Switzerland, polyamides are developed that can be found in many areas of everyday life. In order to investigate the influence of humidity and temperature on the long-term properties of polyamides, the Kappa Multistation with climate chamber (20°C to 90°C, 20% to 90% humidity) was put into operation.