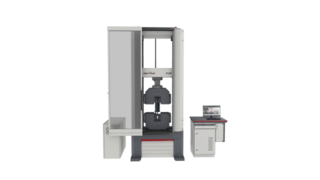

Tensile Testing Machine for High Test Loads From 330 kN

Z330E, Z400E, Z600E, Z1000E, Z1200E, Z1600E, Z2000E, Z2500E Download- Metals

- Composites

- Textiles

- 330 - 2,500 kN

- Tensile

- Compression

- Flexure

- Shear

- ISO 6892

- ISO 15630

- ISO 898

Testing machine with large test loads up to 2,500 kN

E-series electromechanical materials testing machines are used to perform tensile tests, flexure tests, or compression tests with large test loads. A robust frame ensures excellent guiding properties and high machine stiffness. Tensile testing machines from ZwickRoell are equipped with a ball-screw drive and are available in 330 kN, 400 kN, 600 kN, 1000 kN, 1200 kN, 1600 kN, 2000 kN and 2500 kN versions (33 - 250 tons).

The results are displayed in the testXpert testing software in the form of a force travel diagram or a stress strain curve, which is then used to determine material characteristic values such as tensile strength or yield points.

Measuring large specimens. Optically and without markings. With reliability and accuracy.

The videoXtens Array extensometers were developed for tensile tests on large specimens. High-resolution cameras capture the full length of the grip-to-grip separation.

Your benefits:

- Reliable test results for 100% of tests performed

- Measurement without the need for markings

- Wide range of applications for metals

- Strain control to ISO 6892-1 Method A1

Videos on tensile testing machines with high test loads

Technical overview

| Type | Standard | H1-500 | H1+500 | B1+400 | 2 test areas | |

| Item No. | 1012978 | 1013494 | 1013493 | 1013499 | 1013511 | |

| Load frame | ||||||

| Test load FN in tensile/compression directions | 330 | 330 | 330 | 330 | 330 | kN |

| Number of guide columns | 4 | 4 | 4 | 4 | 4 | |

| Number of lead screws | 2 | 2 | 2 | 2 | 2 | |

| Stiffness of load frame at H2 = 1000 mm | 511 | 511 | 511 | 469 | 511 | kN / mm |

| Height - H1 | 3036 | 2536 | 3536 | 3036 | 3010 | mm |

| Width - B1 | 1120 | 1120 | 1120 | 1520 | 1120 | mm |

| Depth - T1 | 775 | 775 | 775 | 775 | 775 | mm |

| Test area width - B2 | 660 | 660 | 660 | 1060 | 660/620 | mm |

| Test area height - H2 | 2130 | 1630 | 2630 | 2065 | 2130 | mm |

| Test stroke - H3 (with hydraulic grips) | 1400 | 900 | 1900 | 1400 | 1400 | mm |

| Weight without accessories | 1850 | 1700 | 1950 | 2600 | 2100 | kg |

| With hydraulic grips | 2250 | 2100 | 2350 | 3000 | 2500 | kg |

| Specific floor load (applied via the machine footprint), with hydraulic grips | 2.7 | 2.5 | 2.8 | 3.6 | 3.0 | kg/ cm2 |

| Noise level at maximum test speed | <70 | <70 | <70 | <70 | <70 | dBA |

| Drive | ||||||

| Drive travel resolution | 0.000197 | 0.000197 | 0.000197 | 0.000197 | ||

| Crosshead speed vmin ... vmax | 0.00005 ... 400 | 0.00005 ... 400 | 0.00005 ... 400 | 0.00005 ... 400 | ||

| Crosshead return speed, max.(at reduced force) | 520 | 520 | 520 | 520 | ||

| Drive travel resolution | 0.000197 | μm | ||||

| Crosshead speed vmin ... vmax | 0.00005 ... 400 | mm/min | ||||

| Crosshead return speed, max. | 520 | mm/min | ||||

| Dimensions |

| Type | Standard | H1-500 | H1+500 | B1+400 | 2 test areas | |

| Item Number | 1007988 | 1013457 | 1013456 | 1013466 | 1005183 | |

| Load frame | ||||||

| Test force FN in tens./comp. direction | 400 | 400 | 400 | 400 | 400 | kN |

| No. of guide columns | 4 | 4 | 4 | 4 | 4 | |

| No. of drive screws | 2 | 2 | 2 | 2 | 2 | |

| Stiffness of load frame at H2 = 1000 mm | 511 | 511 | 511 | 469 | 511 | kN/ mm |

| Height - H1 | 3036 | 2536 | 3539 | 3036 | 3010 | mm |

| Width - B1 | 1120 | 1120 | 1120 | 1520 | 1120 | mm |

| Depth - T1 | 775 | 775 | 775 | 775 | 775 | mm |

| Test-area width - B2 | 660 | 660 | 660 | 1060 | 660/620 | mm |

| Test-area height - H2 | 2130 | 1630 | 2630 | 2065 | 2130 | mm |

| Test stroke - H3 (with hydraulic grips) | 1400 | 900 | 1900 | 1400 | 1400 | mm |

| Weight without attachments | 1850 | 1700 | 2050 | 2700 | 2100 | kg |

| with hydraulic grips | 2250 | 2100 | 2450 | 3150 | 2500 | kg |

| Specific floor loading (with hydraulic grips) | 2.7 | 2.5 | 2.8 | 3.6 | 3.0 | kg/ cm2 |

| Noise level at maximum test speed | <70 | <70 | <70 | <70 | <70 | dBA |

| Drive | ||||||

| Crosshead speed | 0.00005 to 400 | 0.00005 to 400 | 0.0001 ... 400 | 0.00005 to 400 | 0.00005 to 400 | mm/ min |

| Increased crosshead return speed (at reduced force) | 520 | 520 | 520 | 520 | 520 | mm/ min |

| Drive travel resolution | 0.000197 | 0.000197 | 0.000197 | 0.000197 | 0.000197 | μm |

| Type | Standard | H1-500 | H1+500 | H1 +1000 | B1+400 | 2 test areas | |

| Item No. | 1004693 | 1011837 | 1011835 | 1011838 | 1011892 | ||

| Load frame | |||||||

| Test load FN in tensile/compression directions | 600 | 600 | 600 | 600 | 600 | kN | |

| Number of guide columns | 4 | 4 | 4 | 4 | 4 | 4 | |

| Number of lead screws | 2 | 2 | 2 | 2 | 2 | ||

| Stiffness of load frame at H2 = 1000 mm | 925 | 925 | 925 | 853 | 853 | kN / mm | |

| Height - H1 | 3050 | 2550 | 3550 | 4050 | 3050 | 3075 | mm |

| Width - B1 | 1220 | 1220 | 1220 | 1220 | 1620 | 1220 | mm |

| Depth - T1 | 880 | 880 | 880 | 980 | 900 | 880 | mm |

| Test area width - B2 | 710 | 710 | 710 | 710 | 1110 | 710 | mm |

| Test area height - H2 | 2000 | 1500 | 2500 | 3000 | 2000 | 2000 | mm |

| Test stroke - H3 (with hydraulic grips) | 1130 | 630 | 1630 | 2130 | 1130 | 1130 | mm |

| Weight without accessories | 2930 | 2700 | 3100 | 3260 | 4100 | 3350 | kg |

| With hydraulic grips | 3600 | 3350 | 3760 | 3920 | 4740 | 4000 | kg |

| Specific floor load (applied via the machine footprint), with hydraulic grips | 4.3 | 4.0 | 4.5 | 4.7 | 4.8 | kg/ cm2 | |

| Noise level at maximum test speed | <70 | <70 | <70 | <70 | <70 | <70 | dBA |

| Drive | |||||||

| Drive travel resolution | 0.000193 | 0.000193 | 0.000193 | 0.000193 | 0.000193 | 0.000193 | μm |

| Crosshead speed vmin ... vmax | 0.00005 ... 400 | 0.00005 ... 400 | 0.00005 ... 400 | 0.00005 ... 400 | 0.00005 ... 400 | 0.00005 ... 400 | mm/min |

| Increased crosshead return speed (at reduced force) | 520 | 520 | 520 | 520 | 520 | 520 | mm/min |

| Item Number | 1011792 | ||||||

| Test load FN in tensile and compression directions | 600 | ||||||

| Number of lead screw drives | 2 | ||||||

| Rigidity of the load frame at H2 = 1000 mm | 781 | ||||||

| Specific floor load (applied via the machine footprint)(with hydraulic grips) | 5.7 |

| Type | Standard | H1-500 | H1+500 | B1+400 | |

| Item Number | 1085472 | 1085474 | 1085476 | 1085479 | |

| Load frame | |||||

| Test force FN in tens./comp. direction | 1000 | 1000 | 1000 | 1000 | kN |

| No. of guide columns | 4 | 4 | 4 | 4 | |

| No. of drive screws | 2 | 2 | 2 | 2 | |

| Stiffness of load frame at H2 = 1000 mm | 1330 | 1330 | 1330 | 950 | kN / mm |

| Height - H1 | 3350 | 2850 | 3850 | 3350 | mm |

| Width - B1 | 1390 | 1390 | 1390 | 1790 | mm |

| Depth - T1 | 943 | 903 | 903 | 903 | mm |

| Test-area width - B2 | 800 | 800 | 800 | 1200 | mm |

| Test-area height - H2 | 2154 | 1654 | 2654 | 2154 | mm |

| Test stroke - H3 (with hydraulic grips) | 900 | 400 | 1400 | 900 | mm |

| Weight without attachments | 4465 | 4070 | 4670 | 5270 | kg |

| with hydraulic grips | 5870 | 5570 | 6170 | 6770 | kg |

| Specific floor loading (with hydraulic grips) | 173 | 164 | 182 | 200 | kN/m2 |

| Noise level at maximum test-speed | <68 | <68 | <68 | <68 | dBA |

| Drive | |||||

| Crosshead speed | 0.00005 ... 400 | 0.00005 ... 400 | 0.00005 ... 400 | 0.00005 ... 400 | mm/min |

| Increased crosshead return speed (at reduced force) | 550 | 520 | 520 | 520 | mm/min |

| Displacement resolution of drive | 0.000188 | 0.000188 | 0.000188 | 0.000188 | μm |

| Type | Standard | H1-500 | H1+500 | H1+1000 | B1+400 | |

| Item Number | 1015376 | 1021338 | 1021335 | 1021339 | 1021340 | |

| Load frame | ||||||

| Test force FN in tens./comp. direction | 1200 | 1200 | 1200 | 1200 | 1200 | kN |

| No. of guide columns | 4 | 4 | 4 | 4 | 4 | |

| No. of drive screws | 2 | 2 | 2 | 2 | 2 | |

| Stiffness of load frame at H2 = 1000 mm | 1972 | 1972 | 1972 | 1972 | 1034 | kN/ mm |

| Height - H1 | 3635 | 3135 | 4135 | 4635 | 3635 | mm |

| Width - B1 | 1470 | 1470 | 1470 | 1470 | 1870 | mm |

| Depth - T1 | 1063 | 1063 | 1063 | 1063 | 1063 | mm |

| Test-area width - B2 | 830 | 830 | 830 | 830 | 1230 | mm |

| Test-area height - H2 | 2340 | 1840 | 2840 | 3340 | 2340 | mm |

| Test stroke - H3 (with hydraulic grips) | 1080 | 580 | 1580 | 2080 | 1080 | mm |

| Weight without attachments | 6700 | 6200 | 7000 | 7200 | 7600 | kg |

| with hydraulic grips | 8200 | 7600 | 8400 | 8600 | 9000 | kg |

| Specific floor loading (with hydraulic grips) | 2.5 | 2.3 | 2.5 | 2.4 | 2.7 | kg/ cm2 |

| Noise level at maximum test-speed | <68 | <68 | <68 | <68 | <68 | dBA |

| Drive | ||||||

| Crosshead speed | 0.00005 to 400 | 0.00005 to 400 | 0.00005 to 400 | 0.00005 to 400 | 0.00005 to 400 | mm/ min |

| Increased crosshead return speed (at reduced force) | 550 | 550 | 550 | 550 | 550 | mm/ min |

| Displacement resolution of drive | 0.000254 | 0.000254 | 0.000254 | 0.000254 | 0.000254 | μm |

| Type | Z1600E | |

| Item No. | 1022551 | |

| Load frame | ||

| Test load Fmax | 1600 | kN |

| Number of guide columns | 4 | |

| Number of lead screws | 2 | |

| Stiffness of load frame at H2 = 1000 mm | 2200 | kN/mm |

| Height - H1 | 3969 | mm |

| Width - B1 | 1620 | mm |

| Depth - T1 | 1050 | mm |

| Test area width - B2 | 980 | mm |

| Test area height - H2 | 2590 | mm |

| Test stroke - H3 (with hydraulic grips) | 1048 | mm |

| Weight without accessories | 7615 | kg |

| With hydraulic grips | 9835 | kg |

| Specific floor load (applied via the machine footprint), with hydraulic grips | 3. | kg/cm2 |

| Noise level at maximum test speed | <70 | dBA |

| Drive | ||

| Crosshead speed | 0.00005 ... 350 | mm/min |

| Increased crosshead return speed (at reduced force) | 440 | mm/min |

| Drive travel resolution | 0.000167 | μm |

| Description | Value | |

| Type | Z2000E | |

| Item No. | 1019978 | |

| Load frame | ||

| Test load Fmax | 2000 | kN |

| Number of guide columns | 4 | |

| Number of lead screws | 2 | |

| Stiffness of load frame at H2 = 1000 mm | 1643 | kN/mm |

| Height - H1 | 4310 | mm |

| Width - B1 | 2000 | mm |

| Depth - T1 | 1160 | mm |

| Test area width - B2 | 1120 | mm |

| Test area height - H2 | 2736 | mm |

| Test stroke - H3 (with hydraulic grips) | 1200 | mm |

| Weight without accessories | 11819 | kg |

| With hydraulic grips | 14429 | kg |

| Specific floor load (applied via the machine footprint), with hydraulic grips | 212 | kN/m2 |

| Noise level at maximum test speed | <70 | dBA |

| Drive | ||

| Crosshead speed | 0.0001 ... 325 | mm/min |

| Increased crosshead return speed (at reduced force) | 400 | mm/min |

| Drive travel resolution | 0.000124 | μm |

| Description | Value | |

| Type | Z2500E | |

| Item No. | 1017639 | |

| Load frame | ||

| Test load Fmax | 2500 | kN |

| Number of guide columns | 4 | |

| Number of drive lead screws | 2 | |

| Stiffness of load frame at H2 = 1000 mm | 1643 | kN/mm |

| Height - H1 | 4310 | mm |

| Width - B1 | 2000 | mm |

| Depth - T1 | 1160 | mm |

| Test area width - B2 | 1120 | mm |

| Test area height - H2 | 2736 | mm |

| Test stroke - H3 (with hydraulic grips) | 1150 | mm |

| Weight without accessories | 12486 | kg |

| With hydraulic grips | 16052 | kg |

| Specific floor load (applied via the machine footprint), with hydraulic grips | 236 | kg/m2 |

| Noise level at maximum test speed | <70 | dBA |

| Drive | ||

| crosshead speed | 0.0001 ... 275 | mm/min |

| Increased crosshead return speed (at reduced force) | 350 | mm/min |

| Drive travel resolution | 0.000124 | μm |

Information on 600 kN materials testing machines for fiber-reinforced composites can be found on a separate web page.

Typical Test Methods

High-load tensile testing machines are commonly used for metals testing. One specific area of application is testing steel for reinforcement or prestressing of concrete. High test loads are also often required for tests on screws and nuts.

Downloads

- Product information: Electromechanical testing machine 330 kN PDF 496 KB

- Product information: Electromechanical testing machine 400 kN PDF 496 KB

- Product information: Electromechanical testing machine 600 kN PDF 497 KB

- Product Information:Electromechanical testing machine 1000 kN PDF 601 KB

- Product information: Electromechanical testing machine 1200 kN PDF 568 KB

- Product information: Electromechanical testing machine 1600 kN PDF 559 KB

- Product information: Electromechanical testing machine 2000 kN/2500 kN PDF 585 KB

- Product information: Electromechanical testing machine Z330RED PDF 629 KB

- Product information: Electromechanical testing machine Z400RED PDF 393 KB

- Product information: Electromechanical testing machine Z330ES to Z1600ES with side test area PDF 496 KB

- Product information: Electromechanical testing machine Z2000ES / Z2500ES with side test area PDF 655 KB