ASTM D256 - 一個涉及各種測試方法的標準

ASTM D256標準用於對所有塑膠進行 Izod 缺口衝擊試驗,以表述衝擊應力所導致之行為。 彎曲衝擊應力是以側向衝擊方式,施加於一端被夾持固定的缺口試樣上。該測試結果以試樣厚度相關的能量吸收量表示。

該標準支援多種程序、缺口尺寸和缺口排列,以便測試聚合物材料的缺口靈敏度

- 方法 A 適用於 Izod 缺口衝擊強度大於或等於 27 J/m 的塑膠。 在此情況下,請使用 0.25 mm 的缺口半徑。 結果直接依衝擊後擺錘上升高度計算而得。

- 方法 C 用於極脆塑膠材料,其 Izod 缺口衝擊強度小於 27 J/m。 內容與方法 A 相應,但測量衝擊能量需透過計算所得試樣離心功量而校正。

- 方法 D 用於表徵聚合物材料的缺口靈敏度。 此節針對有不同缺口半徑之試樣測量其缺口衝擊強度,缺口靈敏度則以缺口半徑的線性梯度計算。

- 方法 E 用於評估無缺口試樣的衝擊強度。 在此方法中,試樣需旋轉 180° 夾持,使缺口位於與衝擊方向相對的位置。其測試結果僅能有條件地與無缺口試樣的測試結果進行比較。

ASTM D256試樣及尺寸

符合 ASTM D256 標準的試樣其外部尺寸規定為長 2.5 英寸(63.5 mm),高 0.5 英寸(12.5 mm)。注塑成型試樣的寬度可介於 0.118 英吋(3.0 mm) 至 0.5 英吋(12.5 mm) 之間,其中最常見的試樣寬度為 1/8 英吋(3.2 mm)或 1/4 英吋(6.35 mm)。具體細節可參見待測材料的技術規範,或須由相關各方協調確認。若試樣係由部件上加工而成,其寬度通常由部件的壁厚所決定。若試樣取自較薄的壁厚,則依據 ASTM D1822 標準進行衝擊測試。

由於該方法是測量缺口衝擊強度,因此試樣必須預先加工出缺口。

- 針對常用的方法 A,在試樣上銑削半徑為 0.25 mm、45° 角之凹口,使凹口底部保留 0.40 英吋(10.16 角)的高度。

- 若需以方法 D 測量缺口靈敏度,則須準妥具有不同缺口半徑的試樣。 除依據方法 A 製作之標準缺口外,亦需加工製備缺口半徑為 0.04 吋(1.0 公釐)之試樣。

配有符合標準單齒刀具的 ZNO 電動切口切割機可用於準備切口。 針對數量較少之試樣,建議使用配有自動進料功能的手動開槽刨。

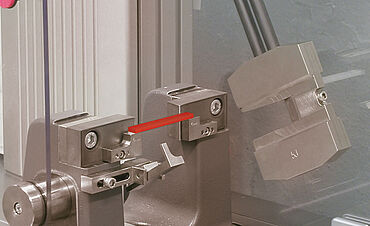

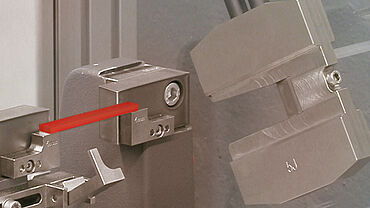

為確保測試準確,缺口必須精確地放置於最大彎矩區域。因此,試樣需以高度擋塊進行定位,或以整合於衝擊夾具中的缺口對準裝置,以便精確可靠地對準試樣。

根據 ASTM D256 執行Izod 懸臂梁缺口衝擊試驗

依據 ASTM D256 標準的 Izod 缺口衝擊測試,使用擺錘衝擊試驗機對塑膠材料進行測試。該擺錘由一根桿體構成,一端為衝擊頭,另一端則連接於低摩擦軸承上。

測量原理是基於一個具有特定能量容量和下落高度的擺錘,當擺錘錘擊試樣時,會釋放部分動能。因此,擺錘在衝擊後無法回到最初的下落高度。故所測量到的下落高度及回升高度之間的差值,即為被試樣吸收的能量。 透過測定下落高度,還可以定義衝擊速度,以便以可重現的應變率執行測試。

依據 ASTM D256 標準,標準擺錘的初始位能為 2.7 焦耳,對應的落下高度為 610 ± 2 mm。若需更高能量的擺錘,可在相同落下高度下,將初始位能加倍以獲得不同規格的擺錘。這將使所有擺錘錘頭的衝擊速度約為 3.46 公尺/秒。

每個擺錘錘頭皆可用於測量其初始勢能最高達 85% 的衝擊能量。若此處可使用多種錘頭尺寸,則應優先選用最輕的擺錘錘頭。

試樣以特定方向夾持,使其缺口正好位於夾持點邊緣,即最大彎矩區域。 由於夾持力度會影響結果,因此氣動夾持或夾持力的控制極有用處。

這種測量方式意味著所有的能量損失都歸因於試樣本身。因此,重要的是要盡量減少、修正或完全消除所有外部誤差來源。對於因空氣摩擦和擺錘軸承點摩擦而不可避免地產生的摩擦損失,我們制定了嚴格的規範,並在定期校正過程中進行檢查。修正值被測量出並分配給相應的擺錘。足夠的儀器質量以及將擺錘衝擊試驗機無振動地安裝在非常穩定的實驗檯面,並用螺栓固定在實心牆壁上的工作檯面或磚石平台上,這些要素對於測試的品質而言皆至關重要。透過設計,最大程度減少了儀器內部的振動。因此,ZwickRoell 使用由單向碳材料所製成的雙桿擺錘,這種材料質量極輕,同時可提供最佳的擺桿剛性,從而確保最小的振動損失。

影片: 用於塑膠測試的擺錘衝擊試驗機

ZwickRoell HIT 系列用於塑膠產業的擺錘衝擊試驗機提供高精度且符合成本效益的解決方案。 擺錘衝擊試驗機的範圍為 5 至 50 焦耳,不僅能夠符合 ASTM D256 抗懸臂擺錘式衝擊標準的性能,還可以根據 ASTM、ISO 和 DIN 標準進行夏比、Dynstat 和拉伸衝擊測試。

Izod懸臂樑和Charpy簡支樑方法之間的差異

兩種方法都以非常相似的方式表徵材料的衝擊強度,因此結果很大程度地相關。

- ASTM 標準中通常使用 Izod 測試法,其中試樣被垂直放置。

- 採用三點彎曲配置的Charpy 衝擊試驗則為 ISO 標準中的首選方法。

- 這兩種方法都用於測量缺口衝擊強度,為此帶缺口的試樣被衝擊,使缺口位於由衝擊所引起的彎曲拉伸區。 對於Izod懸臂梁試驗,此拉伸區域位於擺錘的衝擊側,而對於Charpy試驗則位於相反側。

- Charpy 法在低溫下進行測試時具有多種優勢,因為擺錘衝擊試驗機中試樣的接觸點距離擺錘的衝擊點相對較遠。 如此一來,溫度就不會受到位於相關區域支撐件的影響或降低,並且可以輕鬆地從溫箱供給試樣。

使用 testXpert 軟體實現 ASTM D256 的最佳測試整合

測試軟體的全方位解決方案:符合 ASTM D256 的衝擊強度測試、拉伸測試、彎曲測試、熔體流動測試。 所有數據都能一起評估。

- 多種匯入及匯出可能性確保 testXpert 和 ASTM D256 將衝擊測試完美整合至您的製程。 這套測試軟體能自動將數據讀入其他系統,以及從其他系統讀出數據,例如公司的 ERP 或 LIMS 系統。

- 整合了 ASTM D256 試樣尺寸測量: 測量時,只需要按一下按鈕,試樣的剩餘寬度、高度和寬度就會從測量裝置傳送至 testXpert。

- 根據 ASTM D256 執行的衝擊強度測試、拉伸測試、彎曲測試和熔體流動測試等測得的所有特徵值皆儲存在同一個資料庫內, 所有產業應用的測試數據都能被輕鬆找到、評估以及再現。 透過網路瀏覽器輕鬆從您認為方便的任何位置取得數據。

- 我們的趨勢分析功能可製作出統計製程管制(SPC)圖,讓您能快速偵測出品質規格可能出現的變動。

關於依據 ASTM D256 進行 Izod 衝擊強度測試的常見問題

ASTM D256 是測定塑膠和絕緣材料衝擊強度的國際標準。

ASTM D256 標準描述了使用 Izod 測試法進行衝擊試驗的方式,用以測定塑膠材料的衝擊強度和缺口衝擊強度 。ISO 180 和 ASTM D4508 標準中也描述了 Izod 懸臂樑衝擊試驗。

依據 ASTM D256 的 Izod 懸臂樑缺口衝擊試驗,可在高應變速率下產生用於評估材料抗衝擊性與缺口敏感性的特徵值,這些數值以與厚度相關的能量值形式呈現。根據 ASTM D618,測試通常在 23° / 50% 相對濕度的正常氣候下進行。

本測試用於判定不同模塑材料的可比性、進料檢驗中的公差監控與品質保證、以加工試樣對成品零件進行測試、建立材料卡,以及評估老化效應的量測。

- ASTM D256懸臂樑缺口衝擊試驗以厚度相關能量值的形式生成高應變率下的抗衝擊性 和缺口敏感性特徵值。

- ASTM D4812,一種用於測量無缺口試樣衝擊強度的Izod測試方法

- ASTM D4508,一種用於測量小試片(薄片衝擊)的Izod式測試,它與符合 DIN 53435 的 Dynstat 彎曲衝擊測試相對應。

- ISO 180 描述了用於測定塑料衝擊強度和缺口衝擊強度的Izod衝擊試驗。 它以橫截面相關值的形式提供高應變率下衝擊強度的特徵值。

Charpy 衝擊試驗或 Izod 衝擊試驗測量擺錘撞擊試樣時釋放的衝擊能量可透過擺錘釋放高度與衝擊後上升高度之間的差異來確定。 在 ISO 標準中,衝擊能量與試樣的橫截面積有關,以 [kJ/m²] 為單位,而在 ASTM 標準中,該能量與試樣的厚度有關,以表示衝擊強度(例如以 [ft lbf/in] 為單位)。