Breakaway Force/Glide Force of Syringes, Carpules and Similar Drug-Delivery Systems

Because syringes are used in nearly every medical specialty, it is not just a requirement but also an obligation of syringe manufacturers to ensure maximum safety for patients.

The breakaway force and glide force are important parameters used in the selection of suitable syringes. These forces may not exceed or fall below certain limits to ensure that a safe drug dose is administered. The forces are influenced by the viscosity of the drug and the size of the cannula.

The glide force test is based on standards DIN EN ISO 7886 -1, DIN EN ISO 11499, ISO 11040-4 and ISO 11608-3.

Objective & applications Features of the test device Video Testing systems Testing software Downloads

Objective of determining the breakaway force and glide force on syringes

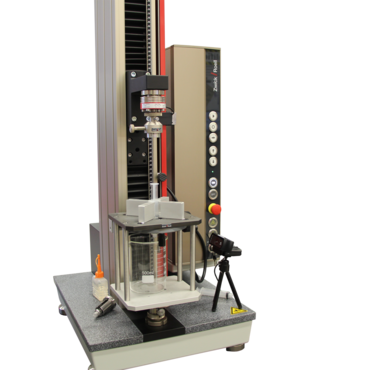

ZwickRoell has developed a special test fixture for tests on syringes, carpules, and similar drug delivery systems to determine the force to move the stopper (breakaway force and glide force).

The test fixture is used to determine the breakaway force and glide force of syringes, carpules and similar drug delivery systems.

With its adjustable specimen holder, the ZwickRoell universal test fixture can accommodate all common syringe geometries. The specimen diameter is adjusted steplessly using a handwheel, without the need for tools. Optional holders facilitate the testing of specimens without finger grips. ZwickRoell’s testXpert testing software enables you to easily test the maximum force and average glide force. The integration of a weigh module makes it possible to determine the dosing accuracy of single doses, such as those in insulin cartridges. A camera documents the glide force of the syringe plunger stopper. The Video Capture Plus option for testXpert III synchronously records the test results and the video signal. With the use of our non-contact video extensometer, you can also continuously measure the thickness of the stopper.

Benefits/features of the test device for determination of the breakaway force:

The test fixture is designed for test forces up to 1 kN and is ideal for syringes with a diameter of 5 to 50 mm and a length of 30 to 150 mm. ZwickRoell's flexible adapter system allows you to quickly install or remove the test fixture, which only weighs 3 kg, from the testing machine.

- Test device consists of a holder at the bottom and a die at the top.

- Includes a glass container to collect escaping fluids.

- Rotatable guide jaws with two different radii ensure optimal guidance.

- Die with concave seat ensures centering of the (syringe) plunger.

- Customized mounts can be easily attached. Fixture has apertures for visual monitoring of glide path.

- Insertion and removal of specimens via a quick release fastener maintains the specimen diameter setting.

- Cartridge holders available as an option for standard sizes 1.5 ml and 3.0 ml.

- testXpert provides the option to directly connect to a scale. The fixture can therefore also be used for dosing accuracy tests to DIN EN ISO 11608-3, for example.

- A safety door is recommended if testing glass syringes.

- This fixture can be used to perform tests on dental cartridges for local anesthesia to DIN EN ISO 11499.

Determination of the breakaway force and glide force

Determination of the breakaway force and glide force of syringes, carpules and similar drug-delivery systems with a zwickiLine

Traceable, tamper-proof test results in accordance with FDA 21 CFR Part 11

- Ever-increasing demands are placed on software used in the medical and pharmaceutical industries to document the traceability of completed actions.

- With the traceability option, testXpert III enables logging of all actions and changes before, during and after the test, making test results and the documentation traceable and protecting them from manipulation.

- Integrated user management and functions such as electronic records and electronic signature ensure that test results are always protected from tampering.

- Together with the organizational measures and procedure instructions that apply to the individual companies themselves, the requirements of FDA in 21 CFR Part 11 are fulfilled.

- ZwickRoell also offers a qualification service package (DQ/IQ/OQ) for validation support.

- testXpert III logs all test and system related actions and settings and can therefore always answer the question “When does who do what, why and who is responsible?”

Learn more about the testXpert III

Traceability option.