ISO 15630-1 / ASTM E488 / BS 4449: Testing of concrete-reinforcing steel

Testing of concrete-reinforcing steel is described in standards ISO 15630-1, ASTM E488 or BS 4449. The applied tests are tensile tests, flexure tests and rebend tests, as well as fatigue tests.

Test Specimen specifications Tensile test Flexure (bend) test/rebend test Fatigue test Testing machines Brochure

Testing of reinforcing bars / reinforcing steel

Concrete-reinforcing steel turns plain concrete into steel reinforced concrete

Because concrete has high compressive strength but lower tensile strength, it is reinforced with embedded concrete-reinforcing steel. Concrete-reinforcing steel is divided into

- Reinforcing bars (rebars), reinforcing wire rod, reinforcing wire

- Welded mats and lattices

Reinforcing bars are steel products with a circular or nearly circular cross-section that are used for the reinforcement of concrete. Test methods for reinforcing bars, reinforcing wire rod and reinforcing wire are described in the ISO 15630-1 standard.

The smaller diameters are processed into mats or lattices before they are poured with concrete on site. Test methods for these products are described in the ISO 15630-2 standard.

A typical feature of concrete-reinforcing steel are ribs, which are coiled or rolled and serve to improve the bond between concrete and steel.

ISO 15630-1 specimen specifications

Concrete-reinforcing steel is manufactured from a long product and its surface shape varies according to the manufacturing standard.

The specimen has a constant cross-section over its length. In addition, the specimen’s shape must be straight without curvature. Specimens with curvature must be straightened before testing.

The cross-section of the specimen is significant for tensile tests. To determine the cross-section, the length of the specimen is measured and it is weighed. The cross-section is then mathematically calculated from these values.

Tensile test on concrete-reinforcing steel

Determination of physical characteristics in a classic tensile test is still the most common test performed on concrete-reinforcing steel. The tensile test is performed to ISO 6892 -1.

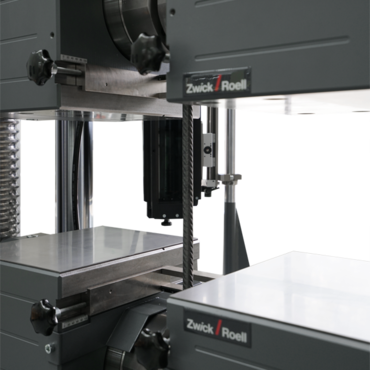

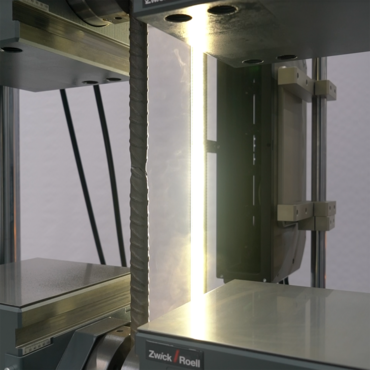

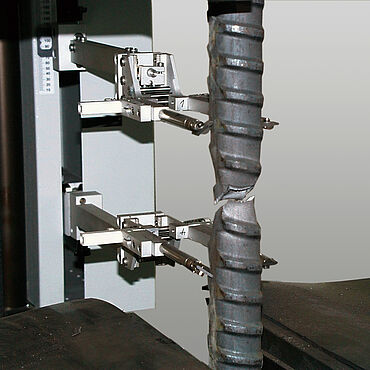

Strain measurement can be performed without making contact (image left + center with videoXtens) or by contact (image right with makroXtens).

Adaptations of ISO 15630-1

- For calculation of the upper yield strength ReH, the offset yield Rp0,2 and the tensile strength Rm, the nominal cross-sectional area is to be used

- The initial gauge length corresponds to five times the nominal diameter (d), if not otherwise specified in a manufacturer’s standard

- When using an extensometer, the percentage total extension at maximum force Agt must be > 0.2% of the maximum value before loss of tensile force

The most important characteristic values

- Tensile strength Rm [MPa]

- Yield point Re [MPa]

- Yield point ratio of tensile strength Rm to yield strength Re

- Ratio of yield strength to nominal yield strength Re, actual / Re, nominal

- Total extension at maximum load Agt [%]

- The nominal cross-sectional area is to be used for calculation of the strength properties, as long as this is not otherwise defined in the product standard concerned (see ISO 15630).

A test is not valid

- If the gradient of the measuring curve deviates >10% from the theoretical value of the Young’s modulus

- In case of breakage within the specimen grips +20 mm or d (whichever is the higher value) distance to the specimen grips.

Automated tensile tests on concrete-reinforcing steel

Concrete-reinforcing steel is produced in large quantities and must be continually tested for production monitoring. ZwickRoell has developed automated systems in which specimens cut to length from rod material or separated from mats and lattices are loaded manually into magazines, after which they are tested completely automatically. Artificial aging at 100° C can also be integrated into this type of testing system. Cross-sections are measured with high accuracy and in accordance with standards, and specimens can be sorted according to test result for later visual inspection.

- Customized total solutions

- Integration of all relevant tests

- High availability

- Useful options for forwarding fault reports

Flexure (bend) test / rebend test on concrete-reinforcing steel

The 3-point flexure test as well as the rebend test are used to determine the bending ability of concrete-reinforcing steel.

During the flexure test to EN ISO 15630-1 , the concrete-reinforcing steel is bent at a predetermined angle (usually 90°). The diameter of the upper anvil and the anvils, and the distance between the anvils are usually specified in the product standard and selected according to the nominal diameter of the concrete-reinforcing steel.

Then the rebend test is performed, in which the specimen is bent back to its initial position. For this test sliding shoes are used which slide away laterally under compression load. The test is successful if the specimen does not show any breakage or cracks. The assessment is performed visually.

The flexure test is performed at ambient temperature. The test can also be performed in a wider temperature range, but requires agreement of the parties concerned.

Fatigue tests on concrete-reinforcing steel to EN ISO 15630-1

- According to standard, concrete-reinforcing steel is required to have a defined fatigue strength or durability, which must be verified.

- These fatigue life tests are most quickly and economically performed using vibrophores (resonance pulsators). The ZwickRoell vibrophore is an ideal solution for this application up to 600 kN.

- Specimens can be up to 36 mm in diameter; from 14 mm they must be grouted, for which a grouting device is available.

Related products for tests to ISO 15630-1

Electromechanical testing machines up to 2,500 kN are used for testing on concrete-reinforcing steel.

For tensile tests, both hydraulic grips (up to 2,500 kN) and wedge grips (up to 600 kN) can be used.

For the performance of flexure (bend) tests flexure tables are used, which are fitted with different upper anvils and anvils, and are mounted on the specimen grips via adapter plates.

Strain measurement can be carried out using a contact-type makroXtens extensometer or a non-contact optical videoXtens extensometer. For non-contact strain measurement the surface structure of the reinforcing steel ribs is used as the gauge mark, which is automatically determined by the videoXtens extensometer.

With the re-run procedure it is possible to subsequently determine elongations within the free grip-to-grip separation Le in tensile tests. This presents the benefit that when a specimen breaks outside of a gauge length Le, the specimen is not invalid. The elongation can be newly measured within a newly set gauge length. Specimen breaks outside of the Le measurement range can thus be excluded.

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!